2 Layer PCBs are the maximum not unusualplace sort of PCB. Plus, 2 layer PCBs also are called double-sided PCBs due to the fact they've additives on each facets of the board.

The 2-layer pcb fabrication is via way of means of bonding layers of copper collectively with a dielectric fabric in among. And the dielectric fabric may be both an FR-forty two or an FR-44.

Furthermore, the copper on every facet can bring specific electric alerts, which makes them best for programs wherein excessive pace and/or dense packaging is necessary. 2 layer pcb also are the maximum low cost sort of PCB to manufacture.

How does a double-layer PCB work?

A 2 layer PCB works via way of means of having electric alerts routed among the 2 layers of copper. Interestingly, those alerts may be both virtual or analog. Plus, the dielectric fabric withinside the center of the board enables to hold those alerts from interfering with every other.

So how thick is a 2 layer PCB?

A 2 layer PCB may be everywhere from 0.010” to 0.060” thick. In addition, the thickness of the board will depend upon the dielectric fabric which you use and the dimensions of the additives set up at the board. Also, the thicker the board, the higher it's far at decreasing crosstalk among the sign traces.

2 layer board stack-up

It's clean that layer 1, or the pinnacle layer is a sign layer on the two layers PCB stack up. Both the pinnacle layer and the lowest layer are copper layers.

Internal layer

he 2-layer pcb has an internal layer which is likewise a copper layer. And that is wherein maximum of the vias get located. Plus, vias are the tiny little holes that join the pinnacle and backside layers collectively. More importantly, they permit for electric alerts to float from one layer to another.

Floor aircraft

The strong floor aircraft is to assist lessen noise in electric alerts. Therefore, we also can use it to offer an area for the electric alerts to go back. Besides that, it additionally enables to distribute warmness higher, and you may use it as a strength or floor layer.

Sign layers

The sign layers are the layers that bring the electric alerts. The 2 layer PCB has sign layers, one for the pinnacle and one for the lowest. Usually, the pinnacle layer that we use for the alerts that want to be routed at the outdoor of the board. While the lowest layer, you may use for the alerts that want to be routed at the internal of the board.

Strength Layer

The strength layer we use to distribute strength to the specific elements of the board. Also, you may use it as a go back route for the floor alerts.

Prepreg Layer

The prepreg layer is a skinny layer of dielectric fabric. And it is able to offer insulation among the copper layer. Besides, it is able to additionally offer assist for the copper layers. The dielectric steady of the prepreg layer is two. 2, that's decrease than the FR-408 dielectric steady.

Solder Masks Layer

The solder masks layer is a skinny layer of fabric that covers the uncovered copper. In addition, it is able to defend the copper from oxidation and corrosion.

Silkscreen Layer

The silkscreen layer is a skinny layer of fabric this is used to print the legends at the board. Also, you may use it to print the board's call and component numbers.

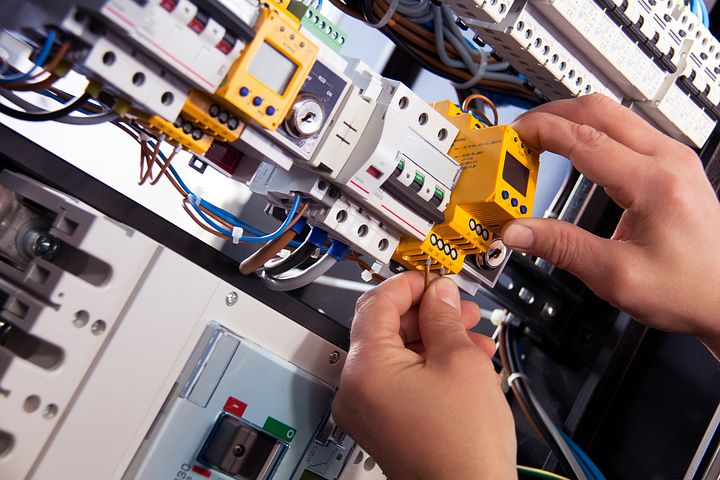

How do You Make a 2-layer PCB /double-sided Circuit Board?

To make a 2 layer PCB, you want first of all a substrate. And the maximum not unusualplace substrate is FR-4. Once you've got got your substrate, you want to feature the copper in layers.

The first layer you introduced is the sign layer. This is wherein it'll bring the electric alerts.

The 2d layer you introduced is the floor layer. And that is wherein the electric alerts will go back to it. Once you've got got your copper layers, you want to feature the prepreg layer.

The prepreg layer is an insulating fabric. As a result, It presents insulation among the layers.

After the prepreg layer, you want to feature the solder masks. The solder masks is a skinny layer of inexperienced or black plastic that enables to defend the copper from brief circuits and corrosion.

Finally, you want to feature the silkscreen. The silkscreen is a white or yellow printing at the PCB that suggests the call of the additives and their values.

Click Here: https://www.nextpcb.com/blog/2-layer-print-circuit-boardpcb-manufacturer

No comments yet