Brushless motor encoders represent a pivotal advancement in the field of motor technology, offering precision, efficiency, and enhanced control in various applications. In this blog, we delve into the intricacies of brushless motor encoders, exploring their functions, advantages, and applications across industries.

Understanding Brushless Motor Encoders

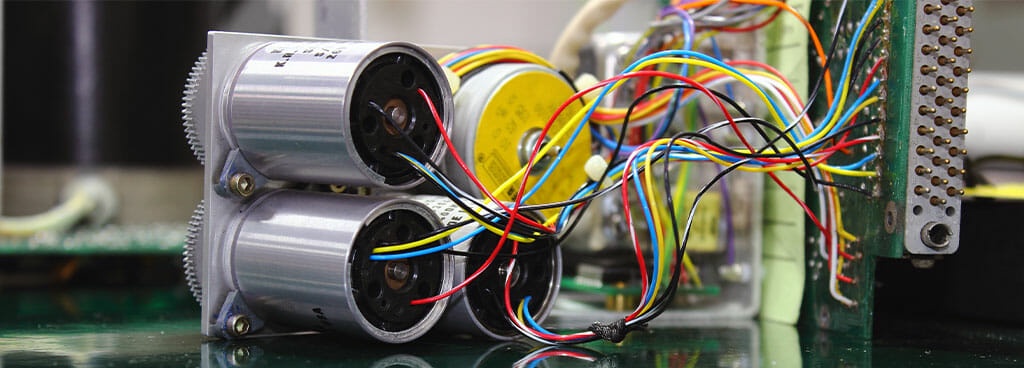

A Brushless Motor Encoder is a device that provides feedback to control systems by measuring the rotational position and speed of a brushless motor. It consists of a sensor and a disc or ring with patterns or slots that interact with the sensor to generate electrical signals. These signals are then processed to determine the motor's position, speed, and direction of rotation.

Key Functions of Brushless Motor Encoders

- Position Sensing: Brushless motor encoders accurately determine the angular position of the motor shaft, allowing precise control over its movement and orientation. This is crucial in applications requiring precise positioning, such as robotics, CNC machines, and automation systems.

- Speed Measurement: By monitoring changes in the encoder signals, brushless motor encoders provide real-time feedback on the motor's speed. This information enables control systems to adjust speed dynamically, ensuring optimal performance and efficiency.

- Direction Detection: Brushless motor encoders detect changes in the direction of rotation, enabling control systems to adjust operation accordingly. This capability is essential for applications where reversible motion is required, such as conveyor systems and actuators.

Advantages of Brushless Motor Encoders

- Precision Control: Brushless motor encoders offer high-resolution feedback, allowing for precise control of motor position and speed. This precision enhances overall system accuracy and performance, particularly in applications with stringent requirements.

- Increased Efficiency: By providing real-time feedback on motor parameters, brushless motor encoders enable efficient operation by optimizing energy consumption and minimizing waste. This leads to improved system efficiency and reduced operating costs.

- Enhanced Reliability: The use of brushless motor encoders improves system reliability and durability by preventing issues such as stalling, overheating, and mechanical wear. This results in longer motor lifespan and reduced maintenance requirements.

- Smooth Operation: With accurate feedback and control, brushless motor encoders contribute to smooth and stable motor operation, reducing vibrations, noise, and oscillations. This is beneficial for applications requiring precise and consistent motion, such as robotics and machining.

Applications of Brushless Motor Encoders

Brushless motor encoders find wide-ranging applications across various industries, including:

- Robotics: In robotic systems, brushless motor encoders enable precise control of robot arms, joints, and end-effectors, ensuring accurate movement and manipulation tasks.

- Industrial Automation: Brushless motor encoders are used in automated machinery and equipment to control conveyor belts, positioning systems, and production processes with high accuracy and reliability.

- Medical Devices: In medical equipment such as surgical robots and imaging devices, brushless motor encoders play a crucial role in achieving precise movements and diagnostic accuracy.

- Aerospace and Defense: Brushless motor encoders are employed in aerospace applications for controlling actuators, drones, and satellite positioning systems, where reliability and precision are paramount.

Choosing the Right Brushless Motor Encoder

When selecting a brushless motor encoder, consider factors such as resolution, compatibility with motor specifications, environmental conditions (e.g., temperature, humidity), and communication interface (e.g., analog, digital, serial). Consulting with motor and encoder experts can help in choosing the most suitable encoder for your specific application requirements.

Conclusion

Brushless motor encoders represent a technological leap in motor control and feedback systems, offering precision, efficiency, and reliability across diverse industries. Their ability to provide accurate position, speed, and direction feedback enhances the performance of motors and automated systems, making them indispensable in modern engineering and manufacturing processes.

Also Read:

Exploring the Power and Precision of AGV Drive Units in Industrial Automation

The Versatility of Side Mount Casters in Industrial Applications

No comments yet