Factory automation engineering holds immense promise for revolutionizing industries and driving progress. This article explores the potential of factory automation engineering in empowering various sectors, its evolution, key components, advantages, and strategies to overcome challenges.

1. Introduction to Factory Automation Engineering

Factory automation engineering involves the utilization of automated systems and technologies to streamline manufacturing processes. It aims to enhance efficiency, productivity, and quality while reducing costs and optimizing resource utilization.

2. The Potential of Factory Automation Engineering in Empowering Industries

Factory automation engineering has the potential to empower industries across sectors by enabling them to achieve higher levels of efficiency, competitiveness, and innovation. From automotive and electronics to pharmaceuticals and consumer goods, factory automation can transform production processes and drive growth.

3. Evolution of Factory Automation Engineering

The evolution of factory automation engineering has been marked by advancements in technology and changing industry needs. From the early days of mechanical automation to the era of digitalization and smart manufacturing, the field has undergone a rapid transformation, paving the way for next-generation solutions.

4. Key Components of Factory Automation Systems

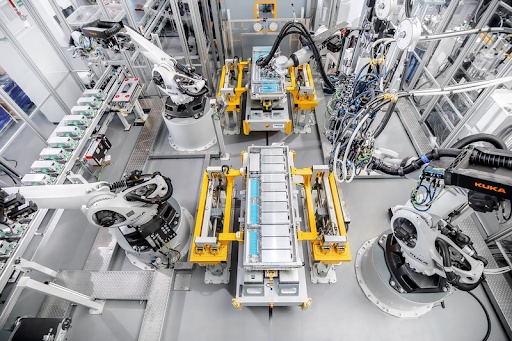

Robotics and Automation

Collaborative Robots (Cobots)

Cobots work alongside human workers, enhancing productivity and safety in manufacturing environments. They perform a variety of tasks, from assembly and material handling to quality inspection, with precision and efficiency.

Automated Guided Vehicles (AGVs)

AGVs are autonomous vehicles used for material handling and logistics within factories. They navigate autonomously, optimizing workflow efficiency and reducing manual labor requirements.

Internet of Things (IoT) Integration

Sensor Networks

IoT integration involves the use of sensor networks to collect real-time data from equipment and processes. These sensors monitor various parameters, providing valuable insights for optimization and decision-making.

Real-time Data Analytics

Real-time data analytics processes the data collected by IoT sensors, providing actionable insights into production processes. By analyzing this data in real-time, manufacturers can identify inefficiencies, predict maintenance needs, and optimize production schedules.

Artificial Intelligence (AI) Applications

Machine Learning Algorithms

Machine learning algorithms optimize production processes, predict equipment failures, and improve overall efficiency by analyzing data and making intelligent decisions autonomously.

Predictive Maintenance Systems

Predictive maintenance systems use AI algorithms to predict equipment failures before they occur, minimizing downtime and maximizing productivity.

5. Advantages of Factory Automation Engineering in Empowering Industries

Factory automation engineering empowers industries by enhancing productivity, improving product quality, reducing costs, and enabling faster time-to-market. By automating repetitive tasks, optimizing workflows, and leveraging advanced technologies, industries can achieve sustainable growth and competitiveness.

6. Overcoming Challenges and Implementation Strategies

While factory automation offers numerous benefits, challenges such as high initial costs, integration complexity, and workforce training may arise. However, by addressing these challenges proactively and implementing a phased approach to automation, industries can maximize the potential of factory automation engineering and drive success.

7. Conclusion

In conclusion, factory automation engineering holds the promise of empowering industries and driving progress across sectors. By embracing advanced technologies, overcoming challenges, and implementing effective strategies, industries can harness the full potential of factory automation engineering and pave the way for a brighter future.

No comments yet