In the rapidly evolving landscape of industrial automation, maximizing the performance of Automated Guided Vehicles (AGVs) is paramount. These autonomous workhorses are revolutionizing logistics and manufacturing processes, driving efficiency, and productivity to new heights. However, ensuring optimal performance, especially in low-light conditions, presents a unique challenge. This is where the integration of low light USB 3.0 cameras comes into play, offering a game-changing solution that enhances AGV functionality and reliability.

The Importance of Low-Light USB 3.0 Camera Integration

AGVs operate in diverse environments, from well-lit warehouses to dimly lit production floors. In scenarios where lighting conditions are less than ideal, traditional cameras may struggle to capture clear and accurate images, hampering the AGV's ability to navigate effectively. This is where low-light USB 3.0 cameras shine, quite literally.

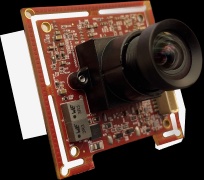

By integrating these advanced cameras into AGV systems, companies can overcome the limitations posed by low-light environments. The high sensitivity of low light USB 3.0 cameras enables them to capture crisp, high-resolution images even in challenging lighting conditions. This ensures uninterrupted operation and reliable performance of AGVs regardless of the ambient light levels.

Key Benefits of Low-Light USB 3.0 Camera Integration for AGVs

-

Enhanced Visibility: Low-light USB 3.0 cameras leverage advanced sensor technology to deliver superior image quality in low-light environments. This enhanced visibility allows AGVs to detect obstacles, read barcodes, and navigate accurately, minimizing the risk of collisions and errors.

-

Improved Efficiency: By operating efficiently in varying lighting conditions, AGVs equipped with low-light USB 3.0 cameras can maintain consistent performance levels throughout the day. This translates to improved productivity and throughput in warehouse and manufacturing operations.

-

Cost Savings: The integration of low-light USB 3.0 cameras eliminates the need for additional lighting equipment or infrastructure modifications to improve visibility for AGVs. This not only reduces upfront costs but also lowers ongoing maintenance expenses, contributing to long-term cost savings.

-

Enhanced Safety: Clear visibility is crucial for ensuring the safety of both AGVs and human operators in shared workspaces. With low light USB 3.0 cameras, AGVs can detect obstacles and hazards with precision, reducing the risk of accidents and injuries in the workplace.

Applications of Low-Light USB 3.0 Camera Integration

The versatility of low-light USB 3.0 cameras extends beyond navigation and obstacle detection. These cameras find applications in various AGV tasks, including:

-

Barcode Reading: Low-light USB 3.0 cameras excel at reading barcodes on packages, pallets, and shelves, facilitating seamless inventory management and order fulfillment processes.

-

Quality Inspection: In manufacturing environments, AGVs equipped with low-light USB 3.0 cameras can perform quality inspections on products with exceptional accuracy, identifying defects and deviations from specifications.

-

Navigation in Unstructured Environments: From dimly lit storage areas to outdoor environments with fluctuating light conditions, low-light USB 3.0 cameras enable AGVs to navigate through diverse landscapes with confidence and precision.

Future Perspectives and Innovations

As technology continues to advance, the integration of low light USB 3.0 cameras is poised to become even more sophisticated. Future innovations may include:

-

AI-Driven Image Processing: Leveraging artificial intelligence (AI) algorithms for real-time image processing, enabling AGVs to make intelligent decisions based on visual data captured by low-light USB 3.0 cameras.

-

Multi-Sensor Fusion: Integration of low-light USB 3.0 cameras with other sensors, such as LiDAR and radar, to provide AGVs with comprehensive situational awareness in complex environments.

-

Miniaturization and Integration: Shrinking the form factor of low-light USB 3.0 cameras for seamless integration into compact AGV designs without compromising performance.

Conclusion

In the realm of AGV technology, maximizing performance and adaptability is crucial for staying ahead in today's competitive market. By integrating low-light USB 3.0 cameras into AGV systems, companies can unlock new levels of efficiency, safety, and reliability, empowering their autonomous fleets to operate seamlessly in any lighting conditions. As we continue to push the boundaries of innovation, the marriage of AGVs and low light USB 3.0 cameras promises a brighter, more efficient future for industrial automation.

for more details visit below website

https://www.vadzoimaging.com/product/imx291-low-light-1080p-usb-camera

No comments yet