One of the most crucial choices in PCB design is PCB colour. To create a distinctive style, you can select from a selection of different hues. Yellow, blue, purple, and green are the most typical PCB colours. There are additional alternatives, though, that you might want to think about. You could pick a non-glossy finish, for example.

Green

The printed circuit board, or PCB color, is one of the most significant electronic components on a circuit board. On one or both sides of the board, there is a thin layer of copper called a PCB. A solder mask is then placed over the PCB.

Despite the fact that PCBs come in a variety of hues, green is the most popular. There are several causes for this. First of all, it is the hue that human eyes can see the easiest. Additionally, it respects the environment.

Second, obtaining it is simple. Additionally, it is reasonably priced. If you buy green paint, that is.

White, red, and blue are additional PCB colours. They are not as helpful as the colour green.

Blue

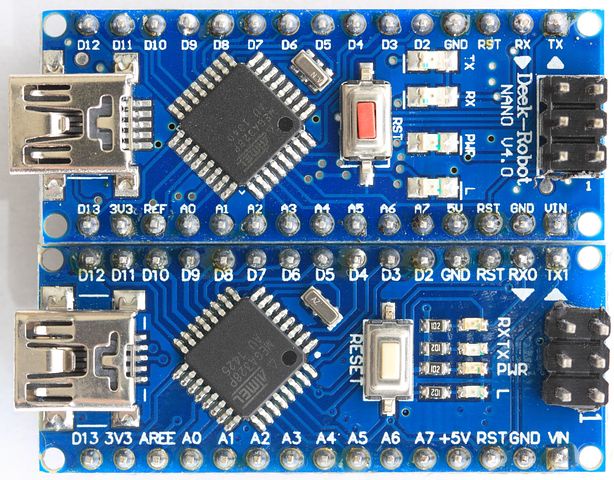

One of the most preferred PCB color for printed circuit boards is blue, according to experts. Consumer electronics, auto parts, navigation systems, sensors, and transmission controls can all make use of it.

Before making your final decision, there are a few things to consider. For instance, you must be aware of how to handle a blue PCB if you wish to use it for repair. Price is another factor to take into account. The blue PCB is less expensive than other PCBs, yet it can still be rather costly.

There are many colours available. Red and green are the most typical. You can choose pink or purple if you want to go with a distinctive colour. They are less vibrant than green or red but more interesting to look at.

Purple

Not only are portable devices but also commercial electronic products a great fit for a purple PCB. Its design is both strong and little. The board is now simple to build and maintain.

There are several techniques to create the purple PCB. For example, you can select a single-sided board that uses the substrate's one side or a double-sided board that utilises both sides.

A solder mask can also be used. The characteristics of the PCB are determined by the solder mask's hue. By selecting a purple solder mask, you might be able to boost your device's performance.

Although having a purple PCB is not necessary, it is a great feature. Before choosing, you need take a few factors into account.

Yellow

Yellow is one of the most striking PCB colours. It is an adaptable hue that may meet many demands. Light-colored residues are simple to remove, and the colour is simple to clean.

Many manufacturers choose colour selections based on aesthetic considerations. Reflectivity, heat conduction, and saleability can all be significantly impacted by colour. For the board's operation, it is not very crucial.

Yellow is a PCB colour that is often used. It ranks as the second most common colour. Despite being widely used, it might be challenging to use in typical applications. It's crucial to take the PCB's intended use and the contrast between the PCB and its components into account when selecting a colour.

A common alternative colour is red. Red isn't always the greatest option, though. For example, it contrasts less than green, which can make it more difficult to inspect. This could lead to issues when making repairs.

Non-glossy

There are numerous colours available for printed circuit boards. While green is the hue chosen by the majority of manufacturers, buyers may find blue, purple, and red to be more appealing. However, these hues may also cost more or present more issues.

Consumers frequently base their decisions on the PCB's colour. A product can be distinguished from a boring, unattractive one by using the proper colour. Additionally, since LED illumination is frequently reliant on the colour of the board, it may be a concern.

A PCB can be finished glossy or non-glossy. Although the fabricator normally decides this, many customers prefer to leave it up to the designer. Glossy surfaces are typically more reflecting. In comparison to their matte counterparts, they are frequently a little brighter and less reflecting.

No comments yet