Plastic mold injection technology has played a pivotal role in shaping modern manufacturing processes, enabling the production of intricate and complex plastic components. As industries continue to evolve, innovations in plastic injection molds have become crucial for enhancing efficiency, precision, and sustainability. In this article, we will delve into the latest advancements in plastic mold injection technology, highlighting how these innovations are reshaping the manufacturing landscape.

Industry 4.0 Integration

One of the most significant trends in plastic mold injection technology is the integration of Industry 4.0 principles. This involves the use of smart technology, data exchange, and automation to create a more connected and efficient manufacturing environment. Injection molding machines are now equipped with sensors and actuators that collect real-time data on various parameters such as temperature, pressure, and cycle times.

This data is then analyzed using advanced algorithms to optimize the injection molding process, ensuring higher precision and reducing waste. Moreover, the integration of Industry 4.0 allows for remote monitoring and control of the injection molding machines, enhancing overall operational efficiency and reducing downtime.

3D Printing for Mold Prototyping

The advent of 3D printing has revolutionized the prototyping phase of plastic mold injection. Traditional methods of creating molds for prototypes were time-consuming and expensive. With 3D printing, manufacturers can now rapidly prototype molds, allowing for quicker iterations and design improvements.

This innovation not only accelerates the product development cycle but also enables designers to experiment with complex geometries and innovative designs that were previously challenging to achieve. 3D-printed molds are cost-effective and can significantly reduce lead times in the early stages of product development.

Advanced Materials for Molds

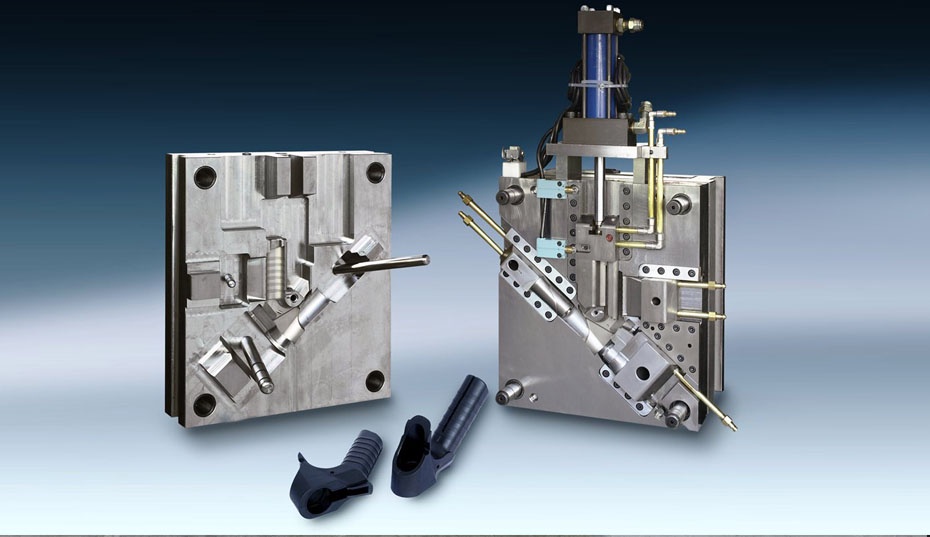

The choice of materials for injection molds has a direct impact on the quality and durability of the final plastic components. Recent innovations in materials science have led to the development of advanced materials specifically designed for injection molding applications. These materials offer improved thermal conductivity, wear resistance, and longevity.

In particular, the use of high-performance alloys and coatings has become more prevalent, extending the lifespan of molds and reducing the need for frequent replacements. This not only contributes to cost savings but also aligns with the growing emphasis on sustainability by reducing material waste.

Micro-Injection Molding for Miniaturized Components

As electronic devices and medical equipment continue to shrink in size, there is a growing demand for the production of miniaturized plastic components. Micro-injection molding has emerged as a specialized technique to meet this demand, allowing for the precise and efficient manufacturing of tiny parts with high tolerances.

This innovation in plastic mold injection technology opens up new possibilities in industries such as electronics, medical devices, and automotive, where the size and precision of components are critical. Micro-injection molding enables the production of intricate and detailed parts that were once thought to be too small for traditional injection molding processes.

Gas-Assisted Injection Molding

Gas-assisted injection molding is a technique that involves the introduction of nitrogen gas into the mold cavity after the initial injection of plastic. This creates channels or voids within the plastic part, reducing material usage and cycle times. This innovative approach results in components with improved surface finish, reduced warpage, and lower production costs.

The use of gas-assisted injection molding is gaining popularity in the production of large, complex parts where maintaining uniform wall thickness is crucial. It is also an effective method for reducing the weight of plastic components without compromising structural integrity, contributing to the overall goal of lightweight and fuel-efficient products.

Biodegradable and Recycled Materials

In response to the global push for sustainability, there is a growing interest in the use of biodegradable and recycled materials in plastic mold injection. Manufacturers are exploring ways to incorporate these eco-friendly materials into their processes without compromising product quality.

Innovations in material formulations and processing techniques have led to the development of biodegradable plastics that meet the performance standards required for various applications. Additionally, the integration of recycled plastic materials into injection molding processes not only reduces environmental impact but also addresses concerns about the disposal of plastic waste.

Conclusion

The continuous evolution of plastic mold injection technology is reshaping the landscape of manufacturing, with a focus on efficiency, precision, and sustainability. From Industry 4.0 integration to the use of advanced materials and techniques like 3D printing and micro-injection molding, these innovations are driving the industry forward.

As we move towards a future that demands more sustainable practices, the adoption of biodegradable and recycled materials in plastic mold injection is a positive step. The combination of these advancements not only enhances the capabilities of plastic injection molds but also aligns with the broader goal of creating a more environmentally conscious and efficient manufacturing ecosystem. The journey of exploration and innovation in plastic mold injection technology continues, promising exciting possibilities for the future of manufacturing.

No comments yet