In the realm of manufacturing, injection molding stands as a beacon of efficiency, producing intricate and versatile components that form the backbone of countless industries. At the heart of this transformative process lies the artistry of injection molded plastics, a method that has revolutionized the way we manufacture intricate and precise parts.

Understanding Injection Molding

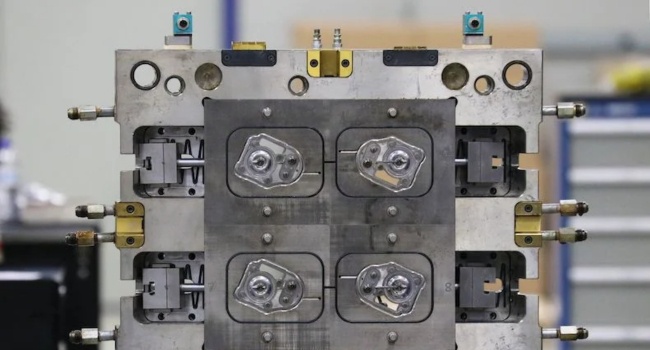

Injection molding is a manufacturing process that involves injecting molten material, typically plastic, into a mold cavity to create a specific shape. This method is widely employed in the production of a myriad of items, ranging from everyday household items to complex automotive components and medical devices.

The Magic Behind Injection Molded Plastics

The key to the success of injection molding lies in its ability to produce high volumes of identical parts with exceptional precision. The process begins with the selection of a thermoplastic resin, which is heated until it reaches a molten state. This molten material is then injected into a carefully crafted mold, where it cools and solidifies, taking the shape of the mold cavity.

Benefits of Injection Molded Plastics

-

Precision and Consistency One of the primary advantages of injection molding is its ability to produce parts with a high degree of accuracy and consistency. The molds used are precisely designed and machined, ensuring that each finished product is an exact replica of the mold.

-

Efficiency in Mass Production Injection molding is a highly efficient method for mass production. The ability to create multiple copies of a part in a single cycle significantly reduces production time, making it a cost-effective solution for large-scale manufacturing.

-

Versatility in Design The versatility of injection molding allows for the creation of intricate and complex shapes. This flexibility in design is particularly beneficial for industries where product aesthetics and functionality are paramount.

-

Material Variety Injection molding supports a wide range of thermoplastic materials, providing manufacturers with the flexibility to choose materials that suit the specific requirements of the end product. From lightweight and durable components to those requiring special characteristics like flame resistance or flexibility, injection molding accommodates diverse material needs.

Applications Across Industries

-

Automotive Sector Injection molded plastics play a crucial role in the automotive industry, providing lightweight and durable components that contribute to fuel efficiency and overall vehicle performance.

-

Medical Devices The medical field benefits from the precision and sterility that injection molding offers. Components such as syringes, medical casings, and surgical instruments are frequently produced using this method.

-

Consumer Goods Everyday items such as kitchen utensils, packaging materials, and electronic device casings owe their uniformity and affordability to injection molding.

Environmental Considerations

While injection molding offers numerous advantages, there is a growing awareness of the environmental impact of plastics. Manufacturers are actively exploring sustainable alternatives, including biodegradable and recyclable materials. The industry is also adopting more energy-efficient processes and recycling programs to minimize the ecological footprint of injection molded plastics.

Future Trends in Injection Molding

As technology continues to advance, the future of injection molding looks promising. The integration of artificial intelligence and automation is enhancing efficiency and reducing production costs. 3D printing is also making its mark, allowing for more intricate and customized mold designs.

Conclusion

The world of injection molded plastics is a testament to the marriage of precision and efficiency. Injection molded plastics have become an integral part of our daily lives, contributing to the advancement of various industries. As technology evolves, the artistry behind injection molding will continue to shape the way we manufacture and interact with the products that define modern life.

No comments yet