In the manufacturing industry, the implementation of efficient filtration systems is crucial for maintaining product quality and reducing operational costs.

One such filtration system that has gained popularity is the Saifilter Candle Filter.

This article will provide a comprehensive cost-benefit analysis of implementing Saifilter Candle Filters in manufacturing processes.

What are Saifilter Candle Filters?

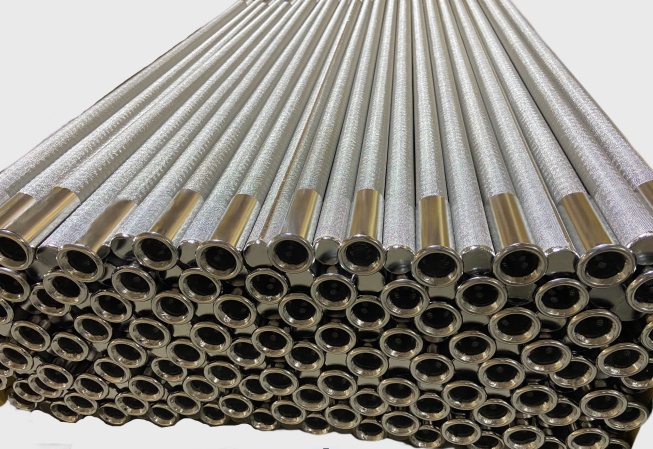

Saifilter Candle Filters are advanced filtration systems designed to remove impurities and contaminants from various manufacturing processes.

These filters consist of cylindrical filter elements, known as candle filters, which are made from high-quality materials such as stainless steel or ceramic.

The unique design of these filters allows for efficient filtration while minimizing pressure drop and maximizing throughput.

Benefits of Implementing Saifilter Candle Filters

Implementing Saifilter Candle Filters in manufacturing processes offers several benefits:

- Improved Product Quality: Saifilter Candle Filters effectively remove impurities and contaminants, resulting in higher product quality and reduced defects.

- Increased Operational Efficiency: These filters have a high filtration capacity and low pressure drop, allowing for increased production rates and reduced downtime.

- Cost Savings: By removing impurities and contaminants, Saifilter Candle Filters help extend the lifespan of equipment and reduce maintenance costs.

- Environmental Sustainability: Saifilter Candle Filters contribute to environmental sustainability by reducing waste generation and minimizing the use of chemicals.

- Regulatory Compliance: Implementing these filters ensures compliance with regulatory standards and requirements related to product quality and environmental impact.

Cost Analysis

When considering the implementation of Saifilter Candle Filters, it is essential to conduct a thorough cost analysis.

This analysis should include the initial investment costs, operational costs, and potential cost savings.

Initial Investment Costs

The initial investment costs of implementing Saifilter Candle Filters include the purchase of the filtration system, installation costs, and any necessary modifications to existing manufacturing processes.

While these costs may vary depending on the specific requirements of each manufacturing facility, they are generally offset by the long-term benefits provided by these filters.

Operational Costs

The operational costs associated with Saifilter Candle Filters include regular maintenance, filter replacement, and energy consumption.

However, these costs are typically lower compared to alternative filtration systems due to the high efficiency and durability of Saifilter Candle Filters.

Potential Cost Savings

Implementing Saifilter Candle Filters can result in significant cost savings for manufacturing facilities:

- Reduced Equipment Maintenance: By removing impurities and contaminants, these filters help prevent equipment damage and reduce the frequency of maintenance activities.

- Extended Equipment Lifespan: Saifilter Candle Filters contribute to the longevity of equipment by minimizing wear and tear caused by impurities.

- Increased Production Efficiency: The high filtration capacity and low pressure drop of these filters allow for increased production rates and reduced downtime, resulting in higher overall operational efficiency.

- Lower Waste Generation: Saifilter Candle Filters effectively remove impurities, reducing the amount of waste generated during manufacturing processes. This can lead to cost savings associated with waste disposal and treatment.

- Minimized Chemical Usage: The efficient filtration provided by these filters reduces the need for additional chemical treatments, resulting in cost savings and a more sustainable manufacturing process.

Implementation Considerations

Before implementing Saifilter Candle Filters, there are several key considerations that manufacturing facilities should take into account:

Process Compatibility

It is essential to assess the compatibility of Saifilter Candle Filters with existing manufacturing processes.

This includes evaluating factors such as temperature, pressure, and chemical compatibility to ensure optimal performance and longevity of the filters.

Installation and Integration

The installation and integration of Saifilter Candle Filters should be carefully planned to minimize disruption to ongoing manufacturing operations.

It is crucial to work closely with the filter manufacturer or supplier to ensure proper installation and seamless integration with existing equipment.

Training and Maintenance

Proper training should be provided to manufacturing personnel responsible for operating and maintaining Saifilter Candle Filters.

Regular maintenance and filter replacement schedules should be established to ensure optimal performance and longevity of the filtration system.

Performance Monitoring

Manufacturing facilities should implement a robust performance monitoring system to track the efficiency and effectiveness of Saifilter Candle Filters.

This can help identify any potential issues or areas for improvement and ensure continuous optimization of the filtration process.

Regulatory Compliance

Manufacturing facilities must ensure that the implementation of Saifilter Candle Filters complies with relevant regulatory standards and requirements.

This includes adherence to product quality standards and environmental regulations related to waste management and emissions control.

Conclusion

Implementing Saifilter Candle Filters in manufacturing processes offers numerous benefits, including improved product quality, increased operational efficiency, cost savings, environmental sustainability, and regulatory compliance.

While there are initial investment costs and operational expenses associated with these filters, the long-term cost savings and overall performance improvements outweigh these costs.

By considering the implementation considerations outlined in this article, manufacturing facilities can successfully integrate Saifilter Candle Filters into their operations and reap the benefits of enhanced filtration.

No comments yet