Saifilter sinter filters are a type of filtration system that offers numerous benefits for various industries.

These filters are designed to remove impurities and contaminants from liquids and gases, ensuring a clean and safe environment.

In this comprehensive guide, we will explore the features and benefits of Saifilter sinter filters, providing you with all the information you need to make an informed decision.

What are Saifilter Sinter Filters?

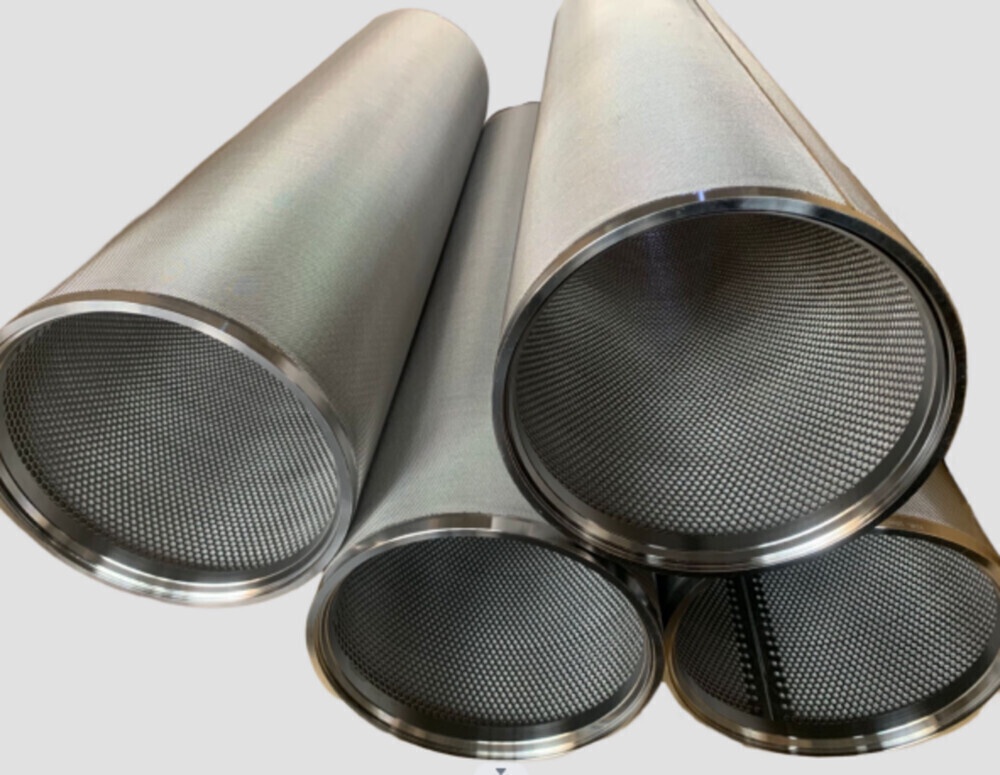

Saifilter sinter filters are advanced filtration systems that utilize sintered metal materials to effectively remove impurities from liquids and gases.

The filters consist of multiple layers of metal particles that are bonded together through a process called sintering.

This creates a porous structure with precise filtration capabilities, allowing only clean fluids or gases to pass through while trapping contaminants.

How do Saifilter Sinter Filters Work?

Saifilter sinter filters work based on the principle of mechanical filtration.

The porous structure of the filter traps particles larger than its pore size, preventing them from passing through.

The sintered metal material used in these filters provides excellent strength and durability, ensuring long-lasting performance even in demanding applications.

The filtration process begins when the fluid or gas enters the filter.

As it passes through the porous structure, contaminants such as dirt, debris, and solid particles are trapped within the filter media.

The clean fluid or gas then exits the filter, ready for further processing or use.

Features of Saifilter Sinter Filters

Saifilter sinter filters offer a range of features that make them highly effective and reliable filtration solutions:

- Precise Filtration: Saifilter sinter filters have a precise filtration capability, with pore sizes ranging from a few microns to sub-micron levels. This allows them to effectively remove even the smallest particles and contaminants.

- High Flow Rates: Despite their efficient filtration capabilities, Saifilter sinter filters offer high flow rates, ensuring optimal performance without compromising productivity.

- Chemical Compatibility: These filters are compatible with a wide range of chemicals, making them suitable for various applications in different industries.

- Temperature and Pressure Resistance: Saifilter sinter filters can withstand high temperatures and pressures, making them ideal for demanding environments.

- Easy Maintenance: These filters are easy to clean and maintain, reducing downtime and ensuring continuous operation.

Benefits of Saifilter Sinter Filters

Saifilter sinter filters offer numerous benefits that make them a preferred choice for many industries:

- Improved Product Quality: By removing impurities and contaminants, Saifilter sinter filters help improve the quality of the final product, ensuring it meets the required standards.

- Extended Equipment Life: The use of sinter filters prevents particles from entering sensitive equipment, reducing wear and tear and extending the lifespan of machinery.

- Cost Savings: Saifilter sinter filters help reduce maintenance costs by preventing clogging and damage to equipment, resulting in fewer repairs and replacements.

- Enhanced Safety: These filters play a crucial role in maintaining a safe working environment by removing harmful contaminants that could pose health risks to employees.

- Environmental Protection: Saifilter sinter filters contribute to environmental protection by preventing the release of pollutants and contaminants into the air or water.

Applications of Saifilter Sinter Filters

Saifilter sinter filters find applications in various industries where the removal of impurities and contaminants is essential.

Some common applications include:

1. Oil and Gas Industry

In the oil and gas industry, Saifilter sinter filters are used to remove solid particles, water, and other contaminants from crude oil, natural gas, and refined products.

This ensures the quality and purity of the fuel and prevents damage to equipment.

2. Pharmaceutical Industry

In the pharmaceutical industry, Saifilter sinter filters are utilized to purify liquids and gases used in drug manufacturing processes.

These filters help maintain the sterility and integrity of the products, ensuring compliance with regulatory standards.

3. Food and Beverage Industry

Saifilter sinter filters play a crucial role in the food and beverage industry by removing impurities, bacteria, and other contaminants from liquids such as water, juices, and beverages.

This helps ensure the safety and quality of the final products.

4. Chemical Industry

In the chemical industry, Saifilter sinter filters are used to purify chemicals and solvents, ensuring they meet the required specifications.

These filters help prevent contamination and maintain the integrity of chemical processes.

5. Automotive Industry

In the automotive industry, Saifilter sinter filters are employed in various applications, including engine oil filtration, fuel filtration, and air intake filtration.

These filters help protect critical components and improve the performance and efficiency of vehicles.

Conclusion

Saifilter sinter filters are highly efficient and reliable filtration systems that offer numerous benefits for a wide range of industries.

With their precise filtration capabilities, high flow rates, and chemical compatibility, these filters provide effective solutions for removing impurities and contaminants from liquids and gases.

By investing in Saifilter sinter filters, industries can improve product quality, extend equipment life, reduce costs, enhance safety, and contribute to environmental protection.

Whether it's in the oil and gas, pharmaceutical, food and beverage, chemical, or automotive industry, Saifilter sinter filters are a trusted choice for achieving clean and safe processes.

No comments yet