In industrial settings, the presence of mist and droplets can be a major concern.

These tiny particles can cause a range of issues, from reduced efficiency and productivity to health and safety hazards.

That's why it's crucial for industries to invest in effective mist elimination systems, such as Saifilter filter bed mist eliminators.

What are Saifilter Filter Bed Mist Eliminators?

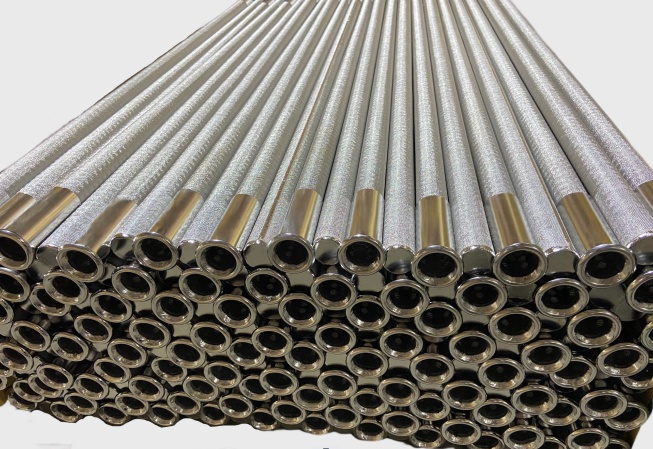

Saifilter filter bed mist eliminators are advanced filtration systems designed to remove mist and droplets from industrial processes.

They consist of a series of filter beds that capture and separate liquid particles from gas streams, ensuring clean and dry air is released into the environment.

The Benefits of Saifilter Filter Bed Mist Eliminators

- Improved Air Quality: Saifilter filter bed mist eliminators effectively remove mist and droplets, improving the overall air quality in industrial settings.

This helps create a healthier and safer working environment for employees. - Increased Efficiency: By eliminating mist and droplets, Saifilter filter bed mist eliminators prevent equipment corrosion and fouling.

This leads to increased efficiency and reduced maintenance costs. - Compliance with Regulations: Many industries are subject to strict regulations regarding emissions and air quality.

Saifilter filter bed mist eliminators help businesses meet these requirements and avoid penalties or legal issues. - Protection of Equipment: Mist and droplets can damage sensitive equipment and machinery.

Saifilter filter bed mist eliminators provide an additional layer of protection, extending the lifespan of valuable assets. - Energy Savings: When mist and droplets are removed from gas streams, the energy required for downstream processes is reduced.

This results in significant energy savings for industrial facilities.

Applications of Saifilter Filter Bed Mist Eliminators

Saifilter filter bed mist eliminators are versatile and can be used in a wide range of industrial applications.

Some common applications include:

1. Oil and Gas Industry

In the oil and gas industry, Saifilter filter bed mist eliminators are used to remove mist and droplets from natural gas streams.

This ensures the gas meets quality standards and prevents damage to downstream equipment.

2. Chemical Manufacturing

Chemical manufacturing processes often produce mist and droplets that need to be eliminated.

Saifilter filter bed mist eliminators are effective in capturing these particles, ensuring clean air is released into the environment.

3. Power Generation

In power generation plants, Saifilter filter bed mist eliminators are used to remove mist and droplets from flue gas streams.

This helps reduce pollution and improve the efficiency of the power generation process.

4. Food and Beverage Industry

In the food and beverage industry, Saifilter filter bed mist eliminators are used to remove mist and droplets generated during various processes, such as cooking, frying, and sterilization.

This helps maintain a clean and hygienic production environment.

5. Pharmaceutical Industry

In the pharmaceutical industry, Saifilter filter bed mist eliminators are used to remove mist and droplets generated during manufacturing processes.

This ensures the production of high-quality and contamination-free pharmaceutical products.

How Saifilter Filter Bed Mist Eliminators Work

Saifilter filter bed mist eliminators work on the principle of impingement and coalescence.

The mist-laden gas enters the filter bed, where the droplets collide with the filter media and impinge on its surface.

This causes the droplets to coalesce and form larger droplets that are then drained away.

The filtered gas then passes through subsequent filter beds, where any remaining mist and droplets are captured and removed.

The clean and dry gas is then released into the environment.

Choosing the Right Saifilter Filter Bed Mist Eliminator

When selecting a Saifilter filter bed mist eliminator for an industrial application, several factors need to be considered:

1. Gas Flow Rate

The gas flow rate determines the size and capacity of the mist eliminator required.

It's important to choose a mist eliminator that can handle the specific flow rate of the gas stream.

2. Particle Size

The particle size of the mist and droplets in the gas stream will determine the efficiency of the mist eliminator.

It's essential to select a mist eliminator that can effectively capture and remove particles of the desired size.

3. Material Compatibility

The mist eliminator material should be compatible with the gas stream and the process conditions.

It should be resistant to corrosion, fouling, and other potential issues that may arise in the specific industrial setting.

4. Maintenance Requirements

Consider the maintenance requirements of the mist eliminator, such as cleaning and replacement of filter media.

Choose a mist eliminator that is easy to maintain and does not disrupt the overall operations of the industrial facility.

5. Cost-effectiveness

Finally, consider the cost-effectiveness of the mist eliminator.

Evaluate the initial investment, operational costs, and potential energy savings to determine the overall value of the system.

Conclusion

Saifilter filter bed mist eliminators play a crucial role in maintaining air quality, protecting equipment, and ensuring compliance with regulations in industrial settings.

By investing in these advanced filtration systems, industries can improve efficiency, reduce maintenance costs, and create a safer working environment for their employees.

With their versatility and effectiveness, Saifilter filter bed mist eliminators are an essential component of any industrial operation.

No comments yet