Table of Contents:

- Introduction

- What is CNC?

- How Does CNC Work?

- Types of CNC Machines

- Advantages of CNC

- Disadvantages of CNC

- Applications of CNC

- Future of CNC Technology

- Frequently Asked Questions (FAQ)

Introduction:

In today's rapidly advancing technological landscape, acronyms like CNC have become commonplace. But what exactly does CNC mean, and how does it impact various industries? This article aims to provide a comprehensive understanding of CNC, its functionalities, applications, and much more.

1. What is CNC?

cnc meaning stands for Computer Numerical Control. It refers to the automation of machine tools through the use of computers executing pre-programmed sequences of commands. These commands, also known as G-codes and M-codes, dictate the movement and operation of the machine, allowing for precise and efficient manufacturing processes.

2. How Does CNC Work?

CNC works by converting design specifications into numerical data that can be interpreted by the machine. This data typically includes coordinates, speeds, and tooling information. The CNC machine then follows these instructions to shape raw materials into finished products with exceptional accuracy and repeatability.

3. Types of CNC Machines

There are various types of CNC machines, each designed for specific applications. Some common examples include:

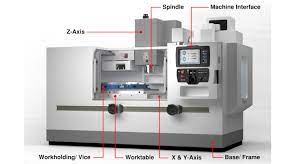

- CNC Milling Machines: Used for cutting and drilling operations, milling machines are capable of producing complex shapes and designs.

- CNC Lathes: Lathes rotate workpieces while cutting tools remove material to create cylindrical shapes.

- CNC Routers: These machines are ideal for cutting and shaping wood, plastic, and other soft materials.

- CNC Plasma Cutters: Employing a high-velocity jet of ionized gas, plasma cutters can effortlessly slice through metal sheets with precision.

4. Advantages of CNC

The adoption of CNC technology offers numerous advantages, including:

- Enhanced Precision: CNC machines can achieve incredibly tight tolerances, ensuring consistent quality in manufactured parts.

- Increased Efficiency: Automation reduces the need for manual intervention, leading to higher production rates and lower labor costs.

- Flexibility: CNC machines can be reprogrammed to produce different parts without extensive retooling, making them highly adaptable to changing manufacturing needs.

- Improved Safety: By minimizing human involvement in hazardous tasks, CNC machines help create safer working environments.

5. Disadvantages of CNC

Despite its many benefits, CNC technology also has some drawbacks:

- High Initial Costs: The acquisition and installation of CNC equipment can be expensive, especially for small-scale operations.

- Skilled Labor Requirements: Operating and programming CNC machines requires specialized training, which may pose challenges for companies lacking skilled personnel.

- Maintenance Complexity: CNC machines demand regular maintenance to ensure optimal performance, adding to operational costs and downtime.

6. Applications of CNC

CNC technology finds applications across various industries, including:

- Aerospace: CNC machining is used to manufacture precision components for aircraft and spacecraft.

- Automotive: CNC plays a crucial role in producing engine parts, chassis components, and other automotive accessories.

- Electronics: CNC is employed in the fabrication of circuit boards, connectors, and other electronic components.

- Medical: CNC machining is utilized to produce surgical instruments, implants, and prosthetic devices with exceptional accuracy.

7. Future of CNC Technology

As technology continues to evolve, the future of CNC looks promising. Advancements in artificial intelligence, machine learning, and automation are expected to further enhance the capabilities and efficiency of CNC systems. Additionally, the integration of IoT (Internet of Things) technology will enable real-time monitoring and predictive maintenance, minimizing downtime and optimizing production processes.

8. Frequently Asked Questions (FAQ)

Q: What industries commonly use CNC technology?

A: CNC technology is prevalent in industries such as aerospace, automotive, electronics, medical, and manufacturing.

Q: How precise are CNC machines?

A: CNC machines can achieve precision levels within micrometers, ensuring exceptional accuracy in manufactured parts.

Q: What programming languages are used to operate CNC machines?

A: CNC machines are typically programmed using G-code, a standardized language for specifying machine operations and movements.

Q: Can CNC machines be retrofitted with new technology?

A: Yes, CNC machines can often be upgraded with the latest software and hardware advancements to improve performance and functionality.

Q: Are CNC machines environmentally friendly?

A: CNC machines can contribute to environmental sustainability by minimizing material waste and energy consumption through optimized manufacturing processes.

In conclusion, CNC technology revolutionizes manufacturing processes by combining precision, automation, and versatility. Understanding its fundamentals and applications is essential for staying competitive in today's industrial landscape. As technology continues to advance, embracing CNC will undoubtedly drive innovation and efficiency across various industries.

No comments yet