The Foundation of Assembling: The Significance of CNC Drills

Introduction

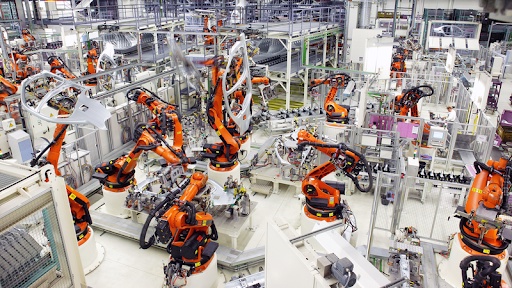

CNC (PC Mathematical Control) drills act as the foundation of present-day fabricating, assuming an urgent role in molding the effectiveness, accuracy, and efficiency of creation processes. This article digs into the meaning of CNC drills in assembling, featuring their significance in driving development and progress in different enterprises.

Outline

Advancement of CNC Drills in Assembling

Key Advantages and Uses of CNC Drills

Accuracy Designing

Improved Efficiency

Flexible Applications

Influences on Assembly Effectiveness and Quality

Background

Conclusion

FAQs

Development of CNC Drills in Assembling

Throughout the long term, CNC drills have evolved from basic mechanical gadgets to modern PC controlled frameworks fit for performing complex tasks with unmatched precision and productivity. Progressions in innovation have changed assembling processes, making CNC drills essential resources in current creation offices.

Key Advantages and Utilizations of CNC Drills

Accuracy Designing

CNC drills succeed in accurate design, considering the making of multifaceted shapes, examples, and openings with micron-level precision. This accuracy guarantees consistency and quality in assembly, limiting mistakes and boosting yield.

Upgraded Efficiency

Via robotizing boring cycles and upgrading apparatus ways, CNC penetrates essentially to increase efficiency and throughput compared with manual boring techniques. They can work constantly for extended periods, lessening personal time and expanding, generally speaking, their effectiveness.

Adaptable Applications

CNC drills track down applications across different enterprises, including car, aviation, gadgets, and clinical gadget fabricating. From boring openings in metal parts to making multifaceted plans in composite materials, CNC drills offer flexibility and versatility for different creation necessities.

Influences on Assembly Effectiveness and Quality

The mix of CNC drills into assembling work processes significantly affects effectiveness and quality. By smoothing out tasks, limiting human blunder, and upgrading asset use, CNC drills contribute to further developed effectiveness, decreased squander, and improved item quality.

Background

CNC drills have become vital devices in present day production, driving advancement, seriousness, and progress in the worldwide market. Makers ceaselessly put resources into CNC innovation to remain on top of things, embracing progressions in computerization, mechanical technology, and advanced availability to streamline creation processes.

Conclusion

CNC drills assume a crucial role in the assembling business, filling in as the foundation of creation processes and empowering organizations to accomplish new degrees of effectiveness, accuracy, and quality. As innovation keeps on progressing, CNC drills will remain imperative resources, forming the fate of assembly and driving development across enterprises.

FAQs

What is CNC penetrating, and how can it vary from regular boring techniques?

CNC penetrating includes the utilization of PC controlled machines to exactly bore openings and make designs in different materials. Not at all like customary boring strategies, CNC penetrating offers more prominent accuracy, mechanization, and flexibility.

What are the essential advantages of utilizing CNC drills in assembly?

CNC drills offer accuracy in designing, upgraded efficiency, and adaptable applications, prompting further developed productivity, quality, and seriousness in assembling tasks.

How do CNC drills contribute to assembling proficiency and quality?

By computerizing penetrating cycles, limiting mistakes, and upgrading asset use, CNC drills increment efficiency, decrease waste, and improve item quality in assembling tasks.

What ventures ordinarily use CNC drill innovation?

CNC drills find applications in businesses, for example, auto, aviation, hardware, and clinical gadget fabricating, where accuracy, productivity, and quality are fundamental.

What variables should organizations consider while incorporating CNC drill innovation into their assembly processes?

Organizations ought to consider factors like creation prerequisites, financial plan imperatives, preparation needs, and an accessible foundation while coordinating CNC drill innovation to guarantee effective execution and augment benefits.

No comments yet