Fluid control systems play a crucial role in industrial settings, regulating the flow of liquids or gases to ensure smooth operations and safety. Here's an overview:

- Purpose: Fluid control systems manage the flow, pressure, and direction of liquids or gases within industrial processes.

- Components: These systems consist of various components such as valves, pumps, actuators, and sensors.

- Functionality: Valves are fundamental in fluid control, directing or stopping the flow as needed.

- Types of Valves: There are different types of valves including ball valves, butterfly valves, and solenoid valves.

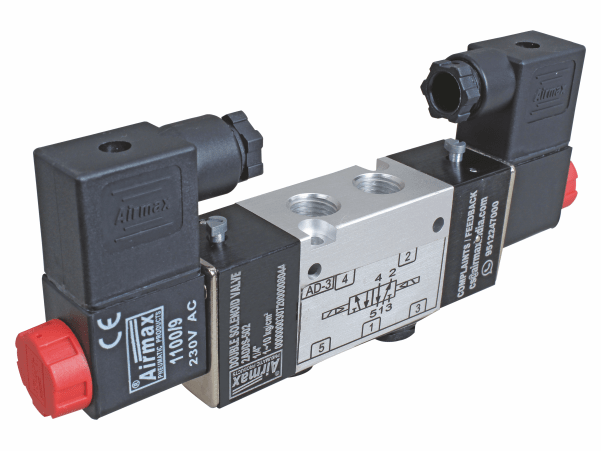

- 5/2 Way Double Solenoid Valve: This particular valve configuration is commonly used for controlling the flow direction in pneumatic systems, offering flexibility and precision control.

- Applications: Fluid control systems find applications across industries like manufacturing, chemical processing, oil and gas, and food processing.

- Importance: These systems enhance efficiency, reduce waste, and ensure safety in industrial processes.

Understanding fluid control systems is essential for optimizing industrial processes and maintaining operational excellence.

Understanding the Basics of Solenoid Valve Functionality

Solenoid valves are electromechanical devices used to control the flow of fluids or gases. They are commonly found in various industries, including manufacturing, automotive, and HVAC systems.

Operating Principle:

- Solenoid valves utilize an electromagnetic coil to generate a magnetic field when energized.

- This magnetic field attracts a plunger or armature, which in turn opens or closes the valve, allowing or stopping the flow of the fluid.

Types of Solenoid Valves:

- 2-Way: Controls the flow of a fluid by opening or closing a single passageway.

- 3-Way: Diverts the flow between two ports.

- 5/2 Way Double Solenoid Valve: A type of valve with five ports and two positions controlled by double solenoids, commonly used for complex control systems.

Applications:

- Used in pneumatic and hydraulic systems for automation and control tasks.

- Found in irrigation systems, medical equipment, and industrial machinery.

Understanding the functionality of solenoid valves is crucial for efficient system design and operation, especially in the case of specialized valves like the 5/2 Way Double Solenoid Valve.

Exploring the Specifics of 5/2 Way Double Solenoid Valves

Functionality:

- Control the flow of air in pneumatic systems.

- Comprise five ports and two states: open and closed.

Operation:

- Utilize two solenoids to control the valve.

- In the default state, the valve maintains a certain position until energized.

Applications:

- Widely used in automation and industrial applications.

- Found in machinery, robotics, and manufacturing processes.

Versatility:

- Offer versatility in controlling the direction of airflow.

- Enable precise control over pneumatic actuators.

Benefits:

- Enhance efficiency by enabling quick switching between different states.

- Facilitate complex automation processes with their flexible control options.

5/2 Way Double Solenoid Valve stands as a cornerstone component in pneumatic systems, ensuring efficient control and operation across various industrial applications.

Importance of Fluid Flow Control in Industrial Processes

Fluid flow control is crucial in industrial processes for optimizing efficiency, maintaining safety, and ensuring consistent product quality. Here's why it's essential:

- Optimized Performance: Proper fluid flow control ensures that processes run smoothly, maximizing productivity and minimizing downtime.

- Safety: Regulating fluid flow prevents overpressure situations, leaks, and other hazards, safeguarding both equipment and personnel.

- Quality Assurance: Precise control of fluid flow helps maintain consistent product quality by ensuring accurate mixing ratios and temperatures.

- Energy Efficiency: Effective flow control reduces energy consumption by avoiding unnecessary pumping or heating of fluids.

- Process Flexibility: Adjustable flow rates allow for flexibility in production, accommodating variations in demand or process requirements.

In achieving these benefits, components like the 5/2 Way Double Solenoid Valve play a critical role, providing reliable control over fluid flow direction and rate. Efficient fluid flow control is indispensable for the smooth operation and success of industrial processes.

Applications of 5/2 Way Double Solenoid Valves in Various Industries

Used in pneumatic systems for controlling air flow in engines and transmissions. Enables precise actuation in automated assembly lines for vehicle manufacturing.

Manufacturing Sector:

- Employed in CNC machines for tool changing operations, ensuring efficient production processes.

- Facilitates the operation of pneumatic actuators in robotic arms for material handling.

Medical Equipment:

- Utilized in medical devices like dental chairs and surgical instruments for precise control of airflow.

- Enables the automation of processes in medical equipment manufacturing, ensuring accuracy and reliability.

Packaging Industry:

- Integrated into packaging machines for controlling the movement of conveyor belts and pneumatic cylinders.

- Ensures accurate filling, sealing, and labeling processes in automated packaging lines.

Agricultural Sector:

- Used in agricultural machinery for controlling the operation of pneumatic actuators in equipment like seeders and harvesters.

- Enables efficient automation in irrigation systems, enhancing crop yield and resource utilization.

5/2 Way Double Solenoid Valves play a crucial role in enhancing operational efficiency and precision across various industries, offering reliable control over pneumatic systems and processes.

Advantages of Using 5/2 Way Double Solenoid Valves for Fluid Control

5/2 way double solenoid valves offer significant benefits for fluid control applications due to their design with two solenoids and three or five ports. Here are some key advantages:

- Versatile Flow Control: A single 5/2 way double solenoid valve can handle both directional control and shut-off functions. This versatility makes them ideal for a wide range of fluid power applications compared to simpler valves that might require multiple units to achieve the same outcome.

- Fast Response Times: These valves feature two solenoids for independent control of each flow path. This enables rapid switching between functions and minimizes downtime in fluid systems.

- High Reliability: The double solenoid design provides redundancy. Even if one solenoid malfunctions, the other can still operate the valve, ensuring continued operation.

Improved Speed in High-Demand Applications: Separate exhaust paths in a Top 5/2 way double solenoid valve allow for quicker exhaust of air pressure. This results in faster actuation times, making them well-suited for high-speed applications like packaging lines or sorting systems.

In applications requiring precise movement control, like robotics or precision machining, separate exhaust paths offer more refined control over the speed of actuation in both directions.

Integration of 5/2 Way Double Solenoid Valves in Automated Systems

In the realm of automated systems, the integration of 5/2 Way Double Solenoid Valves presents a pivotal advancement, optimizing operations across various industries. Here’s how:

- Versatility: 5/2 Way Double Solenoid Valves offer flexible control over pneumatic actuators, enabling precise regulation of airflow direction and pressure.

- Enhanced Efficiency: By facilitating rapid switching between two air flow paths, these valves streamline processes, minimizing downtime and maximizing productivity.

- Improved Control: Integration of these valves allows for precise manipulation of actuator movements, leading to smoother and more accurate operations.

- Cost-Effectiveness: The efficient utilization of compressed air, coupled with the durability and reliability of 5/2 Way Double Solenoid Valves, results in long-term cost savings.

- Compatibility: These valves seamlessly integrate with existing automated systems, offering a hassle-free upgrade path for enhanced functionality.

The integration of 5/2 Way Double Solenoid Valves marks a significant stride towards optimizing automation processes, promoting efficiency, and driving productivity to new heights.

Factors Influencing Selection and Installation of Solenoid Valves

Application Requirements:

- Consider the specific function the solenoid valve needs to perform.

- Evaluate factors such as flow rate, pressure, temperature, and fluid compatibility.

Environmental Conditions:

- Assess the operating environment for factors like humidity, temperature variations, and exposure to chemicals or contaminants.

- Choose materials and coatings resistant to corrosion and wear.

Electrical Considerations:

- Determine voltage, current, and power requirements for proper operation.

- Ensure compatibility with existing electrical systems and controls.

Size and Configuration:

- Select the appropriate size and configuration based on space constraints and system design.

- Consider factors such as port size, mounting options, and accessibility for maintenance.

Reliability and Durability:

- Opt for solenoid valves from reputable manufacturers known for quality and reliability.

- Assess factors like lifespan, maintenance requirements, and warranty coverage.

When selecting and installing solenoid valves, such as the 5/2 Way Double Solenoid Valve, careful consideration of these factors ensures optimal performance and longevity in various industrial applications.

Maintenance and Troubleshooting Guidelines for 5/2 Way Double Solenoid Valves

Regular maintenance and proper troubleshooting are essential for ensuring the efficient operation of 5/2 Way Double Solenoid Valves. Here are some guidelines to follow:

- Regular Inspection: Conduct routine visual inspections to check for any signs of wear, corrosion, or leaks.

- Cleanliness: Keep the valve and its surrounding area clean to prevent dirt or debris from interfering with its operation.

- Lubrication: Apply appropriate lubricants to moving parts to ensure smooth operation and prevent friction-related issues.

- Testing: Perform regular testing of the valve to ensure it functions correctly and responds promptly to control signals.

- Troubleshooting: In case of malfunctions, follow a systematic approach to diagnose and rectify the issue promptly.

- Component Replacement: Replace any worn-out or damaged components promptly to prevent further damage to the valve.

Remember, proper maintenance and troubleshooting practices are crucial for maximizing the lifespan and performance of your 5/2 Way Double Solenoid Valve.

No comments yet