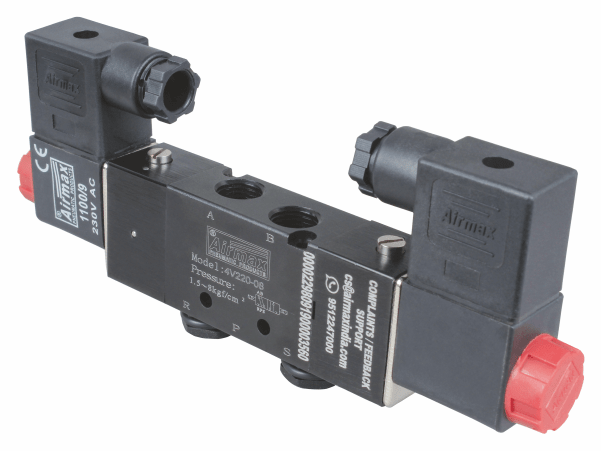

Solenoid valves control fluid flow with electrical signals, making them versatile workhorses in various industries. But within this category lies a critical decision: single or double coil? Understanding their differences empowers you to choose the right valve for your application.

Single Coil:

- Cost-effective: Simple design for budget-conscious projects.

- Power-driven state: Requires constant power to maintain open or closed position.

- Spring-based reset: Automatically returns to default state when power stops.

- Ideal for: On/off applications where power consumption isn't crucial.

Double Coil:

- Bi-stable operation: Maintains state (open or closed) without continuous power.

- Independent control: Each coil activates different flow positions.

- Power-efficient: Saves energy in applications with frequent state changes.

- Versatile: Enables complex flow control and bi-directional operations.

- Ideal for: Applications requiring specific state retention, power conservation, or multi-directional flow control.

By understanding the nuances of single and double coil solenoid valves, you're empowered to make an informed decision for your application. And when it comes to double coil solutions, prioritize top quality manufacturers in India to guarantee optimal performance and value.

Pros and Cons of Single Coil Solenoid Valves: A Detailed Analysis

Single coil solenoid valves offer a simple and cost-effective solution for controlling fluid flow. But are they the best fit for your application? Let's explore their key advantages and disadvantages:

Pros:

- Cost-effective: Single coils are generally cheaper than their double coil counterparts, making them suitable for budget-conscious projects.

- Simple design: Their straightforward construction facilitates easy installation, maintenance, and repair.

- Fast response: They offer rapid opening and closing times, ideal for applications requiring quick fluid flow changes.

- Low power consumption: They typically operate on low power, reducing energy costs and heat generation.

- Compact size: Their smaller size allows for integration into space-constrained applications.

Cons:

- Limited control: They only offer two positions (open/closed), lacking the flow control options available in double coil valves.

- Susceptible to pressure fluctuations: Performance can be affected by variations in fluid pressure, potentially leading to leaks or incomplete closure.

- Higher operating temperature: They may operate at higher temperatures compared to double coils, requiring appropriate materials and cooling strategies.

- Not ideal for high-pressure applications: Their design limitations make them less suitable for handling high-pressure fluids.

For simple on/off flow control in low-pressure applications, single coil valves can be a viable choice. However, for precise flow control, high-pressure handling, or demanding environments, consider exploring top quality double coil solenoid valve manufacturers in India. They offer greater versatility and control, ensuring optimal performance for your specific needs.

Examining the Advantages of Double Coil Solenoid Valves in Control Systems

In control systems demanding high accuracy and reliability, double coil solenoid valves stand out as a powerful solution. These valves leverage two independent coils to deliver precise flow control, making them ideal for various applications. Let's explore their key advantages:

- Enhanced Flow Control: Each coil independently controls a specific flow path, enabling fine-tuning and bi-directional flow manipulation. This level of control surpasses single-coil valves, offering greater flexibility and responsiveness.

- Multiple Flow Configurations: Double coil valves offer diverse flow configurations, including normally closed, normally open, and multi-position options. This versatility caters to a wide range of control needs, from simple on/off switching to complex, multi-stage processes.

- Faster Response Times: The independent coils allow for quicker energization and de-energization, leading to faster response times and improved system dynamics. This is crucial for applications requiring rapid response to changing conditions.

- Reduced Power Consumption: By selectively energizing individual coils, double coil valves can achieve efficient power management, especially in applications requiring frequent switching. This translates to lower operating costs and reduced environmental impact.

- Increased Reliability: The redundant coil design enhances system reliability. If one coil fails, the other can still operate, ensuring continued functionality and minimizing downtime risk.

To unlock the full potential of double coil solenoid valves, partnering with a reputable manufacturer is essential. Look for a company known for its commitment to top quality materials, rigorous testing procedures, and a proven track record of performance.

Comparative Analysis: Response Time of Single Coil vs. Double Coil Solenoids

Solenoid valves play a vital role in automating processes across diverse industries. Selecting the right valve type, however, is crucial for optimal performance. When considering response time, which is the time taken for the valve to fully open or close, both single coil and double coil solenoids offer distinct advantages:

Single Coil Solenoids:

- Faster response time: Simpler design leads to quicker actuation, ideal for high-speed applications.

- Compact size: Requires less space, making them suitable for space-constrained setups.

- Cost-effective: Generally more affordable than double coil solenoids.

Double Coil Solenoids:

- Enhanced control: Separate coils allow for independent control of opening and closing speeds, enabling precise flow regulation.

- Lower power consumption: Holding current is minimal once desired position is reached, reducing energy usage.

- Higher flow rates: Larger size often accommodates higher flow capacities compared to single coils.

The optimal choice depends on your specific application needs. If rapid response and cost-effectiveness are primary concerns, single coil solenoids might be ideal. For applications demanding precise flow control and energy efficiency, double coil solenoids offer distinct advantages.

Energy Efficiency Considerations: Single Coil vs. Double Coil Solenoid Valves

Choosing the right solenoid valve for your application can significantly impact your energy consumption. Here's a breakdown of energy efficiency considerations for single coil and double coil valves:

Single Coil:

- Lower initial cost: Less complex design makes them generally cheaper.

- Continuous power required: Valve relies on constant power to maintain its state, leading to ongoing energy use.

- Suitable for short activation cycles: Efficient for applications where the valve is frequently switched on and off.

Double Coil (Bistable):

- Higher initial cost: More complex design with two coils.

- Low power consumption: Only requires power to change state, not to maintain it, leading to significant energy savings over time.

- Ideal for long activation cycles: Efficient for applications where the valve remains in one state for extended periods.

Looking for a top-quality double coil solenoid valve manufacturer in India? Explore the offerings from leading companies known for their energy-efficient designs and commitment to sustainability.

Reliability and Redundancy: How Single and Double Coil Valves Differ

Solenoid valves are the workhorses of automation, controlling fluid flow in countless applications. But when it comes to reliability and redundancy, understanding the difference between single and double coil options is crucial.

Single Coil Valves:

- Cost-effective: Simple design translates to lower initial cost.

- Compact size: Ideal for space-constrained applications.

- Susceptible to failure: A single coil malfunction renders the valve inoperable.

Double Coil Valves:

- Enhanced reliability: Each coil acts independently, ensuring operation even if one fails.

- Redundancy for critical systems: Ideal for applications where downtime is unacceptable.

- Increased complexity: Requires additional wiring and control logic, raising costs.

Choosing the Right Valve:

The choice between single and double coil valves depends on your specific needs:

- For basic applications with minimal downtime risk, single coil valves offer a cost-effective solution.

- For critical systems or applications demanding maximum uptime, double coil valves provide essential redundancy.

If you require the superior reliability and redundancy of double coil valves, consider sourcing them from a reputable manufacturer in India. Look for a company with a proven track record of quality, reliability, and customer service.

Installation and Wiring Challenges: Single Coil vs. Double Coil Solenoids

Choosing the right solenoid valve for your application requires considering multiple factors, including installation and wiring complexities. Let's explore how single and double coil solenoids differ in these aspects:

Single Coil:

- Installation: Generally easier to integrate due to a single set of connections.

- Wiring: Simpler setup with one power source needed.

- Limitations: Offers limited control over flow direction or speed regulation.

Double Coil:

- Installation: Requires more planning for separate connections to each coil.

- Wiring: More complex, involving individual control of each coil, potentially needing additional control circuitry.

- Benefits: Enables bi-directional flow control, variable flow rates, and potentially faster response times.

For simple on/off applications, a single coil solenoid might suffice. However, if your project demands precise flow control, bi-directional operation, or speed adjustments, a double coil solenoid offers greater flexibility. Remember, the added complexity comes with a slightly higher cost and installation effort.

No comments yet