Industrial packaging is a critical component of modern supply chains, serving to protect, preserve, and transport a wide range of products and materials across diverse industries. At its core lies a complex interplay of materials, design, and functionality aimed at ensuring the safe and efficient handling of goods. This blog will delve into the secrets of industrial packaging, shedding light on the importance of its structure, versatility, and impact across various sectors.

Material Selection and Strength

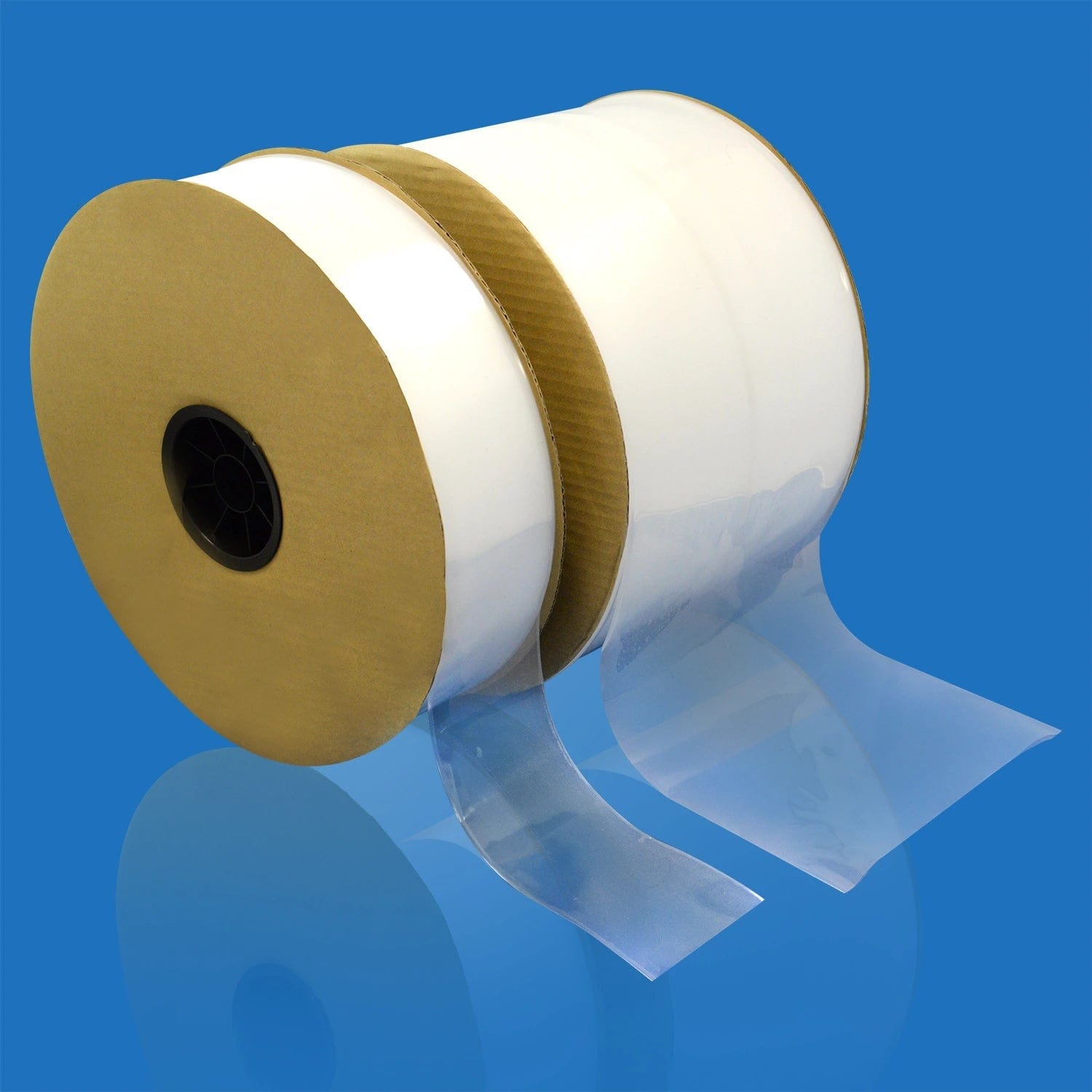

Layered Protection: Industrial packaging often involves layered materials to provide strength, durability, and protection against environmental factors. This may include corrugated cardboard, foam inserts, plastic wraps, and metal reinforcements.

Customization: The ability to tailor the material composition and thickness to specific goods ensures optimal protection, making industrial packaging suitable for items ranging from delicate electronics to heavy machinery parts.

Environmental Considerations

Sustainability: The adoption of recyclable and biodegradable materials in industrial packaging supports eco-friendly practices and aligns with the growing emphasis on sustainability. Packaging designed with minimized environmental impact contributes to a circular economy.

Protection Against Elements: Industrial packaging is designed to shield goods from moisture, temperature variations, and other environmental stressors, ensuring their integrity throughout the supply chain.

Efficient Handling and Transport

Weight Distribution: Industrial packaging is engineered to distribute the weight of goods evenly, facilitating safe and stable handling during loading, unloading, and transportation operations.

Integration of Handling Features: The inclusion of handles, forklift cut-outs, and stacking features enhances the maneuverability and compatibility of industrial packaging with various handling equipment, streamlining logistics processes.

Customization and Innovation

Product-Specific Solutions: Industrial packaging can be tailored to the unique requirements of diverse products, considering factors such as size, weight, fragility, and shelf life, demonstrating its versatility across industries.

Advanced Design Technologies: The incorporation of technologies such as 3D modeling, rapid prototyping, and structural analysis allows for the development of innovative and efficient packaging solutions that meet specific industrial needs.

Compliance and Safety Standards

Regulatory Requirements: Industrial packaging must adhere to global and local safety regulations, including those related to hazardous materials, transportation, and storage, ensuring the protection of both products and personnel.

Impact Resistance: Industrial packaging undergoes rigorous testing to ensure its ability to withstand impacts, vibrations, and sudden movements, safeguarding the goods against damage or breakage.

Just-in-Time Manufacturing and Distribution

Optimized Production Processes: Industrial packaging plays a pivotal role in just-in-time manufacturing and distribution by enabling efficient inventory management, reduced wastage, and timely delivery of goods to end users.

Supply Chain Integration: Packaging that aligns seamlessly with automated handling and distribution systems supports the fluidity and cost-effectiveness of just-in-time operations.

Future Innovations and Sustainability Efforts

Smart Packaging Solutions: The integration of IoT sensors, RFID tags, and smart tracking systems into industrial packaging is poised to offer real-time monitoring, supply chain transparency, and enhanced security for goods in transit.

Circular Economy Initiatives: Continued research and development in reusable, returnable, and recyclable industrial packaging solutions will drive significant reductions in waste and environmental impact across industries.

Industrial packaging, with its multifaceted roles in safeguarding goods, logistics optimization, and sustainability, encapsulates the strength in layers. Its intricate design, adaptability, and compliance with safety standards have far-reaching implications for the safe and efficient movement of goods globally. As industry demands and environmental consciousness continue to evolve, the secrets of industrial packaging will continue to be unlocked through innovation, customization, and sustainable practices.

No comments yet