In today's fast-paced industrial landscape, ensuring the safety and integrity of your products is paramount. Whether you're shipping delicate electronics or heavy machinery parts, choosing the right packaging can make all the difference. Industrial packaging offers a comprehensive solution to safeguard your goods throughout the supply chain, from manufacturing to delivery. Let's delve into why industrial packaging is essential and explore some key considerations for selecting the right solution for your needs.

The Importance of Industrial Packaging

Industrial packaging serves as a shield against various external factors that can compromise the quality and condition of your products. From moisture and dust to impact and vibration, the journey from production facility to end-user can subject goods to numerous hazards. Proper packaging minimizes the risk of damage, reducing the likelihood of costly returns and repairs.

Furthermore, industrial packaging plays a crucial role in optimizing logistics and storage efficiency. By providing sturdy containers and pallets, it facilitates safe handling and stacking, maximizing space utilization in warehouses and transportation vehicles. This not only streamlines operations but also reduces transportation costs and environmental impact.

Key Features to Look for in Industrial Packaging

When selecting industrial packaging solutions, several factors should be taken into account to ensure maximum protection and efficiency:

- Durability: Choose packaging materials that are robust enough to withstand the rigors of transportation and storage. Corrugated cardboard, wood, plastic, and metal are popular options known for their strength and resilience.

- Customization: Every product has unique requirements, so opt for packaging solutions that can be tailored to fit your specific dimensions and specifications. Customized packaging minimizes excess space and reduces the need for additional cushioning materials.

- Safety Features: Look for packaging designs that incorporate features such as cushioning, bracing, and shock absorption to safeguard your products against impact and vibration during transit. Foam inserts, inflatable airbags, and corrugated dividers are examples of effective protective measures.

- Moisture and Environmental Protection: If your products are susceptible to moisture damage or corrosion, consider packaging solutions with moisture-resistant coatings or barrier films. Additionally, eco-friendly packaging options made from recyclable or biodegradable materials can help reduce your carbon footprint and appeal to environmentally conscious consumers.

- Compliance with Regulations: Ensure that your chosen packaging meets relevant industry standards and regulations, particularly if you're shipping hazardous materials or perishable goods. Compliance with regulations not only protects your products but also mitigates the risk of legal liabilities.

Types of Industrial Packaging

Industrial packaging includes a broad range of products designed for different markets and uses. Some common types include:

- Boxes and Cartons: Corrugated cardboard boxes and cartons are versatile packaging options suitable for a wide range of products, from small components to large equipment. They offer excellent protection against impact and can be customized to accommodate different shapes and sizes.

- Crates and Pallets: Wooden crates and pallets are ideal for heavy-duty applications where durability and stability are essential. They provide secure containment and easy handling, facilitating efficient loading and unloading processes.

- Flexible Packaging: Flexible packaging, such as plastic bags, pouches, and shrink wrap, offers lightweight and cost-effective solutions for protecting products from moisture, dust, and contaminants. It's particularly well-suited for items with irregular shapes or sizes.

- Drums and Barrels: For liquids, powders, and bulk materials, drums and barrels made of steel, plastic, or fiberboard provide secure containment and easy dispensing. They're commonly used in industries such as chemicals, pharmaceuticals, and food processing.

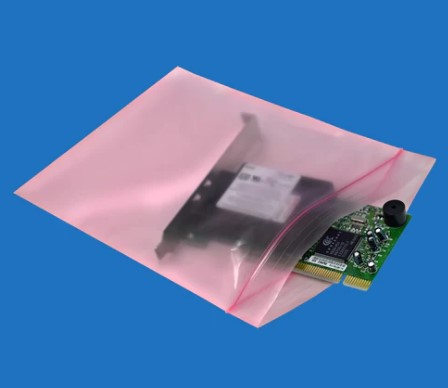

- Specialty Packaging: Some products require specialized packaging solutions to address specific needs, such as temperature-sensitive pharmaceuticals or static-sensitive electronics. Specialty packaging may include insulated containers, anti-static bags, and tamper-evident seals.

Industrial packaging plays a vital role in safeguarding your products throughout the supply chain, ensuring they reach their destination safely and intact. By choosing the right packaging solutions and considering factors such as durability, customization, and compliance, you can protect your investments and enhance customer satisfaction. Invest in industrial packaging today and keep your products safe and secure.

No comments yet