Electromagnetic interference (EMI) can be a significant nuisance in our digitally-driven world, where electronic devices are foundational to our daily lives. EMI can disrupt or degrade the performance of electrical circuits, an issue particularly pressing in sensitive environments like hospitals or aerospace applications. Enter EMI gaskets: the unsung heroes in the battle against unwanted electromagnetic noise. In this article, we take a closer look at EMI gasket technology and its applications, shedding light on how this critical component is helping to ‘shut out the static’ in various industries.

Shutting Out the Static: A Closer Look at EMI Gasket Technology and Applications

Fundamentals of EMI Gaskets

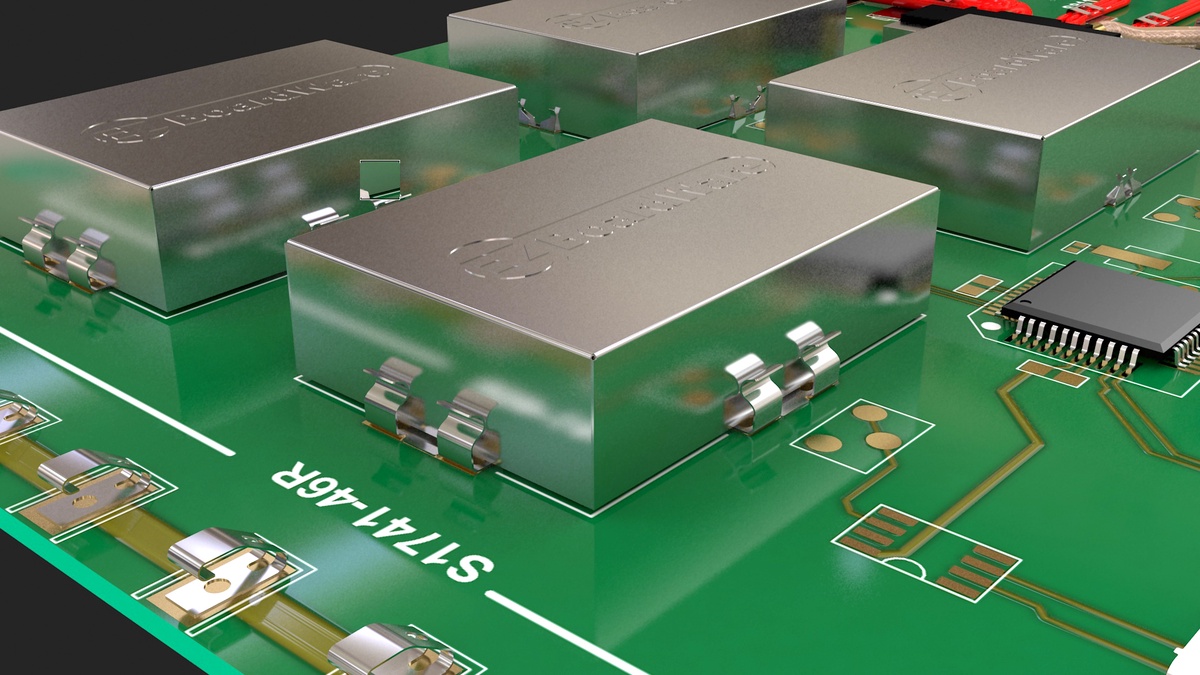

EMI gaskets are specialized components designed to protect electronic equipment from external and internal electromagnetic interference. These gaskets create a conductive seal, bridging gaps between metal surfaces in electronic enclosures, preventing the leakage of electromagnetic fields that can disrupt electronic signals. The effectiveness of an EMI gasket is often determined by its material properties, shape, and the application in which it is used.

Materials Used in EMI Gaskets

The materials chosen for EMI gaskets are pivotal in their performance. Conductive silicones, elastomers, and metals are commonly used, with each offering unique benefits. For instance, conductive silicone gaskets provide excellent environmental sealing in addition to EMI shielding. Metals like beryllium copper or aluminum are chosen for their high conductivity and resilience, making them suitable for demanding applications such as military or aerospace equipment.

Innovations in EMI Gasket Design

Recent technological advances have enabled the development of EMI gaskets that are more efficient and easier to install. For example, fabric-over-foam gaskets offer a soft, compressible structure with a conductive exterior, ideal for uneven surfaces. Advances in materials science have also led to the creation of EMI gaskets that can withstand extreme temperatures and environmental conditions, ensuring reliable performance in any scenario.

Applications of EMI Gasket Technology

The applications of EMI gasket technology are extensive and varied. In the medical field, EMI gaskets are crucial in ensuring that sensitive equipment, such as MRI machines and patient monitors, are free from interference that could lead to misdiagnoses or equipment malfunction. In the consumer electronics sector, they are used in devices like smartphones and laptops to prevent interference that can affect performance and data integrity.

The aerospace and defense industries particularly benefit from EMI gaskets. Aircraft, satellites, and military equipment often operate in environments with high levels of electromagnetic noise. EMI gaskets are vital in these applications, ensuring that navigation, communication, and operational systems function without interference.

The Role of EMI Gaskets in Compliance

Regulatory standards such as the FCC in the United States and the EMC Directive in the European Union necessitate the use of EMI gaskets in various electronic devices. These regulations are in place to ensure that electronic devices do not emit interference that could affect other equipment. EMI gaskets play a crucial role in enabling companies to meet these regulatory requirements, thereby avoiding the costly implications of non-compliance.

Looking to the Future

As the proliferation of electronic devices continues, and with the advent of 5G technology and the Internet of Things (IoT), the importance of EMI gasket technology is only set to increase. The future may see the development of ‘smart’ gaskets that can adapt their shielding properties in real-time, offering dynamic protection against EMI.

Conclusion

EMI gaskets are an essential component in protecting electronic equipment from electromagnetic interference. Their use across a wide array of industries underscores their importance in today’s electronic-centric society. With ongoing advances in materials and design, EMI gasket technology is well-positioned to meet the growing demand for reliable electromagnetic shielding solutions. By shutting out the static, EMI gaskets ensure that our devices and equipment continue to operate at their best, free from the potentially disruptive forces of EMI.

No comments yet