In the world of modern electronics, where devices are becoming increasingly compact and interconnected, the need to address electromagnetic interference (EMI) has become more critical than ever. EMI can disrupt the proper functioning of electronic devices, leading to malfunctions, data corruption, and potential safety hazards. This is where EMI gaskets come into play as crucial components in designing electronic systems that can withstand EMI challenges effectively. In this article, we'll explore best practices for designing with EMI gaskets to ensure the reliability and performance of electronic devices.

Understanding EMI and Its Impact

Before delving into EMI gasket design practices, it's essential to understand what electromagnetic interference is and how it can affect electronic devices. EMI refers to the unwanted electromagnetic emissions or disturbances that can disrupt the normal operation of electronic systems. These disturbances can originate from various sources, including nearby electronic devices, power lines, and wireless communications.

EMI can manifest as:

- Radiated EMI: EMI that propagates through the air as electromagnetic waves, affecting nearby electronic devices.

- Conducted EMI: EMI that travels through electrical conductors, such as power lines or data cables, impacting devices connected to those conductors.

- Coupling EMI: EMI that occurs when electromagnetic fields couple with electronic circuits, inducing unwanted electrical currents and voltages.

The consequences of EMI can range from minor inconveniences, such as audio static in headphones, to critical safety hazards, such as EMI affecting medical equipment or automotive electronics.

The Role of EMI Gaskets in Design

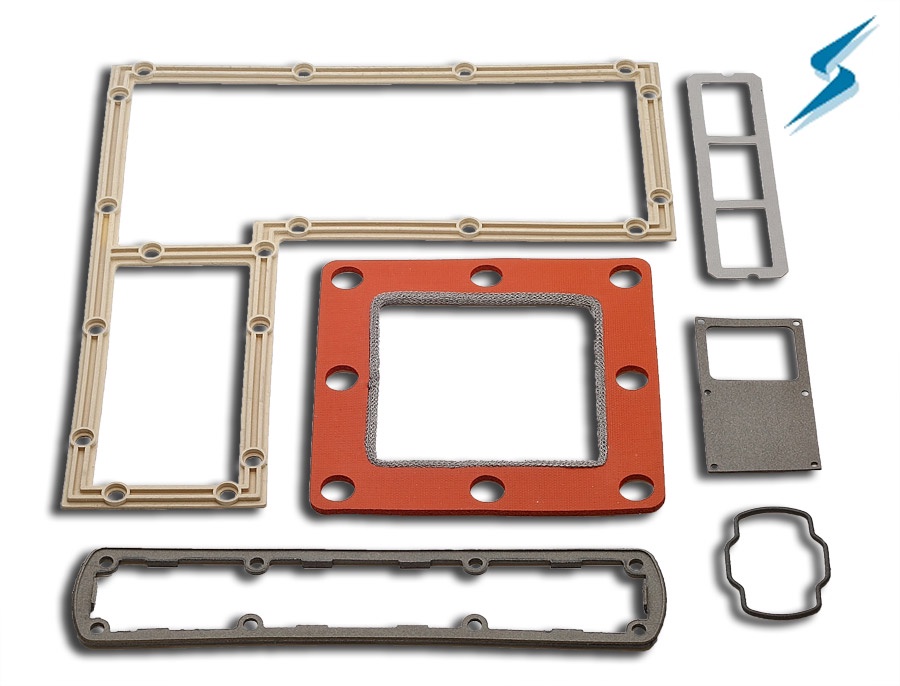

EMI gaskets are specialized sealing components designed to create a conductive or shielding barrier around sensitive electronic components or enclosures. These gaskets prevent electromagnetic interference from either escaping or entering electronic devices. They are a fundamental part of EMI suppression strategies and are used to ensure the reliable operation of electronic systems.

Now, let's explore some best practices for effectively designing with EMI gaskets:

- Early Integration into Design

To maximize the effectiveness of EMI gaskets, it's essential to incorporate them into the design process from the beginning. Waiting until the final stages of a project to address EMI concerns can lead to costly redesigns and delays. By involving EMI gasket design early on, you can seamlessly integrate them into your electronic system's layout.

- Comprehensive EMI Analysis

Conduct a thorough analysis of the electromagnetic interference environment your electronic device will be exposed to. Identify potential EMI sources, frequencies, and the levels of interference. This analysis will help you determine the types and locations of EMI gaskets needed for effective protection.

- Material Selection

Choose the appropriate EMI gasket material for your specific application. EMI gaskets come in various materials, including conductive elastomers, metal foils, and conductive fabrics. The choice of material should consider factors such as the frequency range of interference, environmental conditions, and sealing requirements.

- Customization and Precision

EMI gaskets should be custom-designed to fit the specific dimensions and shapes of your electronic enclosures and components. Precisely engineered gaskets ensure a secure and effective EMI shield.

- Proper Compression

Achieving the right compression level is crucial for EMI gasket performance. Over-compression can damage the gasket, while under-compression may result in ineffective shielding. Follow the manufacturer's guidelines to ensure the correct compression level.

- EMI Gasket Mounting

Pay attention to how EMI gaskets are mounted within your electronic device. Proper mounting techniques, such as using conductive adhesives or mechanical fasteners, ensure good electrical contact and consistent shielding.

- Continual Testing and Validation

Throughout the design and development process, regularly test and validate the effectiveness of your EMI gasket solutions. This can involve conducting EMI tests, such as radiated emissions and susceptibility testing, to ensure that your designs meet the required EMI standards.

- Environmental Considerations

Consider the environmental conditions in which your electronic device will operate. EMI gaskets should not only provide electromagnetic interference shielding but also protect against moisture, dust, and other environmental factors that can compromise device performance.

- Compliance with Standards

Ensure that your EMI gasket designs comply with relevant industry standards and regulations. This is particularly important in industries like automotive, aerospace, and healthcare, where EMI standards are stringent and non-compliance can have serious consequences.

- Collaboration and Expertise

Seek collaboration with EMI experts or consult with EMI gasket manufacturers who can provide valuable insights and guidance in designing effective EMI shielding solutions.

In conclusion, designing electronic systems with EMI gaskets in mind is crucial to ensuring the reliable and interference-free operation of modern electronic devices. By incorporating these best practices into your design process, you can effectively address EMI challenges and deliver electronic products that meet performance and compliance standards while minimizing the risk of interference-related issues. EMI gaskets play a vital role in modern electronics, enabling us to enjoy the benefits of increasingly compact and interconnected devices without compromising on reliability and performance.

No comments yet