Silicone, known for its incredible flexibility and resilience, has undoubtedly made its mark in a plethora of industries. Whether you glance at automotive parts, kitchen tools, or even electronics, it’s everywhere. While the inherent properties of silicone make it a favorite, what if we told you there’s a way to boost its performance even further? Enter the game-changer: carbon black for silicone. By incorporating this unique additive, silicone’s features can be enhanced in several ways, setting new standards and broadening horizons. Let’s delve deep into this synergy and understand its significance.

Improved Mechanical Properties

One of the primary reasons for blending carbon black with silicone is the enhancement of its mechanical properties. The combination leads to better strength, durability, and even elongation. When carbon black for silicone is introduced, it serves as a filler, lending more rigidity and toughness to the material. This means that products made from this amalgamation can withstand greater physical stresses, making them ideal for applications where durability is paramount.

Enhanced Thermal Stability

Heat can sometimes be a foe to many materials, causing them to degrade or lose their intended properties. However, the union of carbon black and silicone proves to be a winning formula against this challenge. Carbon black for silicone offers an impressive increase in thermal stability. With this elevated heat resistance, silicone products can maintain their integrity and functionality even under extreme temperatures. Whether it’s under the hood of a car or within a high-performance electronic device, this pairing ensures longevity and reliable performance.

Superior Electrical Conductivity

Silicone, by its nature, is an insulator. However, certain applications demand electrical conductivity. This is where the role of carbon black comes into play. By incorporating carbon black for silicone, the blend transforms into a conductive material. This conductivity is not just about passing electrical current but also aids in static dissipation. Such a feature is vital in industries where static buildup can be detrimental, such as electronics or fuel hoses. With carbon black in the mix, silicone can cater to a broader spectrum of needs without compromising safety or efficiency. For more details visit us at https://www.cficarbonproducts.com/.

Resistance to UV and Ozone

The elements are often relentless, and materials exposed to the environment have to contend with factors like ultraviolet (UV) radiation and ozone. Over time, these elements can deteriorate the quality of materials, leading to discoloration, loss of strength, or premature aging. However, when we talk about carbon black for silicone, we’re discussing a partnership that provides a formidable shield against such environmental challenges. Carbon black, by its nature, absorbs UV rays, preventing them from breaking down the silicone matrix. Moreover, its integration improves silicone’s resistance to ozone, ensuring that the material remains robust and unaffected even in challenging outdoor conditions.

Versatility in Coloring and Aesthetics

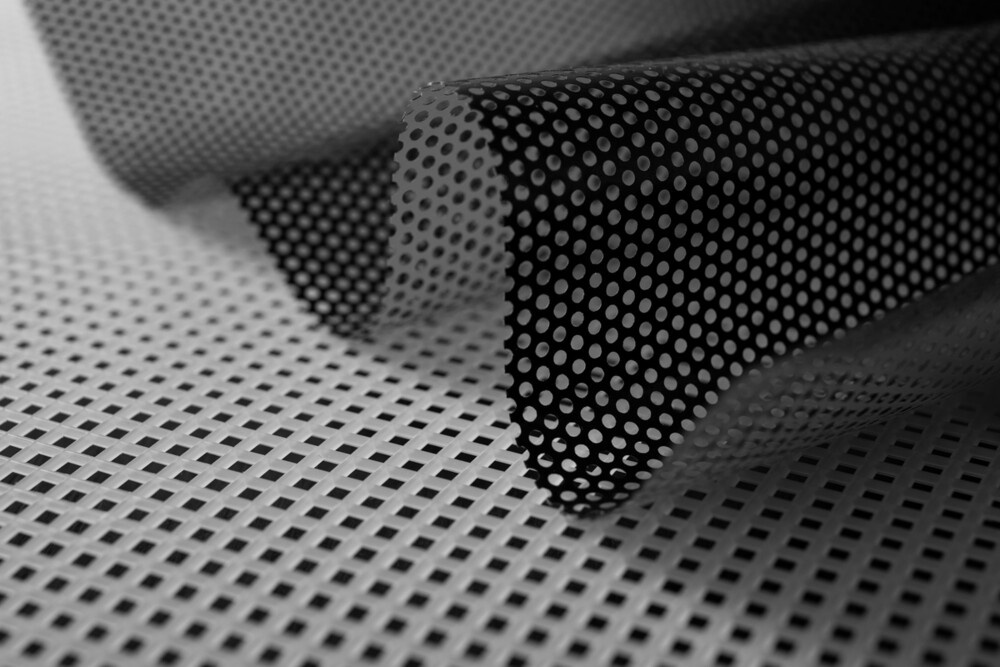

While functionality is paramount, aesthetics can’t be ignored, especially in consumer-facing products. Carbon black for silicone not only augments the performance of the material but also imparts a deep, rich black color. This inclusion offers manufacturers an avenue to produce products that are not just high-performing but also visually appealing. From sleek automotive parts to stylish kitchen gadgets, the blend allows for a perfect balance between form and function.

Cost-Effective Solutions

Optimizing the performance of a material often comes with the perception of added costs. Surprisingly, with carbon black for silicone, industries find a cost-effective means to upgrade. Carbon black, being a robust and readily available additive, doesn’t break the bank. When incorporated into silicone, it allows manufacturers to create superior products without a steep rise in production costs. This affordability ensures that end consumers get the best of both worlds – top-notch products without a hefty price tag.

Conclusion

In the world of materials and their applications, evolution is the key to progress. As industries move forward, the demand for more resilient, efficient, and versatile materials will only increase. Silicone, already a favorite for its distinct attributes, finds an incredible ally in carbon black. Together, they redefine the possibilities, setting new standards for durability, resilience, and versatility.

From enhancing mechanical strengths to offering protection against environmental factors, and even adding a touch of aesthetics – carbon black for silicone proves that sometimes, it’s the right combination that makes all the difference. For manufacturers and industries alike, this blend not only promises superior product performance but also assures cost-effectiveness.

In the end, as we stand at the intersection of innovation and application, the union of carbon black and silicone showcases a promising path forward, lighting the way for a future where materials are not just better but are tailored to meet the ever-evolving needs of our modern world.

Learn More:

Carbon Black in Plastic

Carbon Black

No comments yet