The paint industry is a highly demanding industry, with strict regulations on product quality and safety. In order to meet these regulations, paint manufacturers need to ensure that their pipelines are clean and free of contamination. Pigging systems are a reliable and effective way to clean pipelines in the paint industry.

What is pigging?

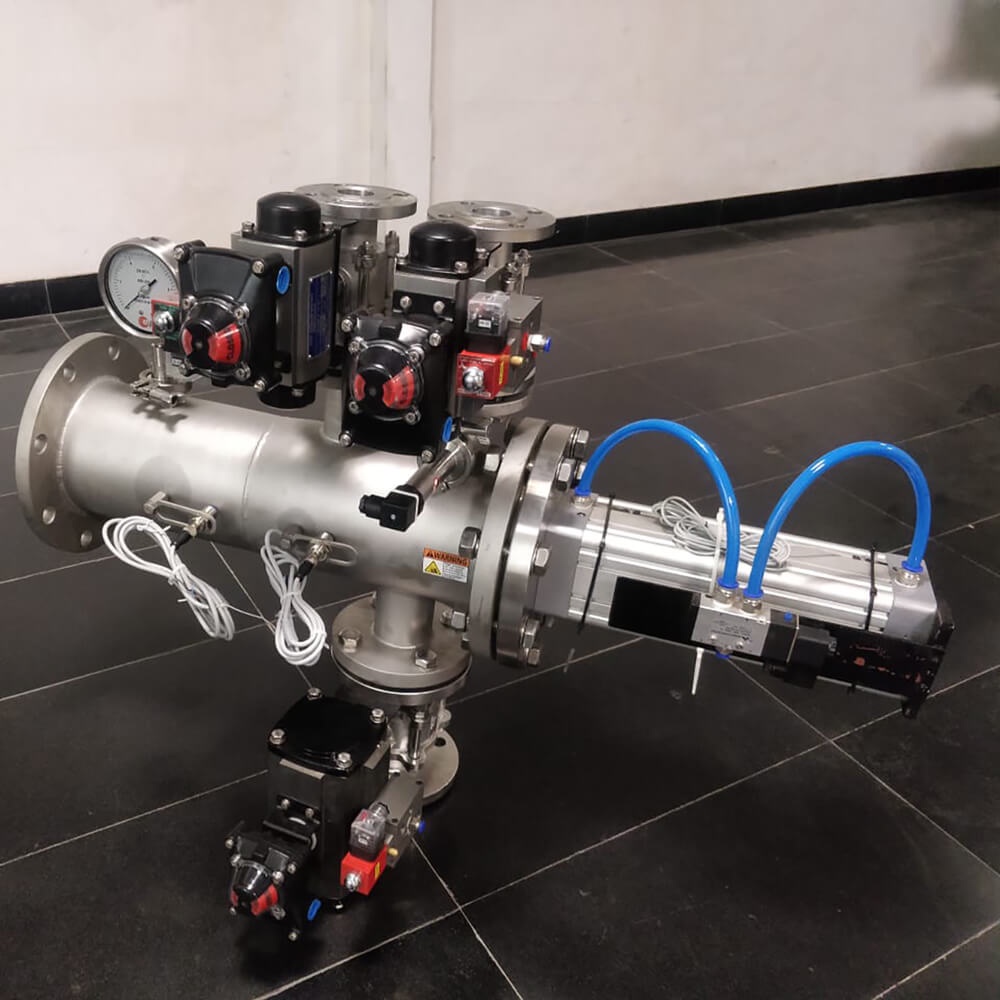

Pigging is a process that uses a device called a pig to clean pipelines. The pig is a cylindrical object that is slightly larger than the inside diameter of the pipeline. It is made of a durable material, such as plastic or metal, and it has a number of bristles or scrapers on its surface. When the pig is propelled through the pipeline, it scrapes away any residual product that is left behind.

Benefits of pigging for the paint industry

There are many benefits to using pigging systems for the paint industry. These benefits include:

Reduced product waste: Pigging systems can help to reduce product waste by recovering residual product from the pipeline. This can save manufacturers money and help to protect the environment.

Improved product quality: Pigging systems can help to improve product quality by removing any contaminants from the pipeline. This can help to prevent product spoilage and ensure that the product meets quality standards.

Increased plant safety: Pigging systems can help to increase plant safety by reducing the risk of leaks and spills. This is because the pigs help to clean the pipeline and remove any potential hazards.

Reduced downtime: Pigging systems can help to reduce downtime by allowing for faster and more efficient cleaning of pipelines. This can help manufacturers to get their plants back up and running more quickly.

Types of pigging systems

There are two main types of pigging systems: manual pigging systems and automatic pigging systems. Manual pigging systems are the simplest type of pigging system. They are operated by hand and are typically used for small-scale applications. Automatic pigging systems are more complex, but they are also more efficient. They are typically used for large-scale applications and can be operated remotely.

Conclusion

Pigging systems are a valuable tool for paint manufacturers. They can help to reduce product waste, improve product quality, increase plant safety, and reduce downtime. If you are a paint manufacturer, you should consider investing in a pigging system.

No comments yet