Air motors are invaluable tools in various industries, known for their reliability and efficiency. To ensure your air motor operates at its best for years to come, proper maintenance is essential. In this guide, we'll provide you with maintenance tips to help prolong the lifespan of your air motor.

Understanding Your Air Motor:

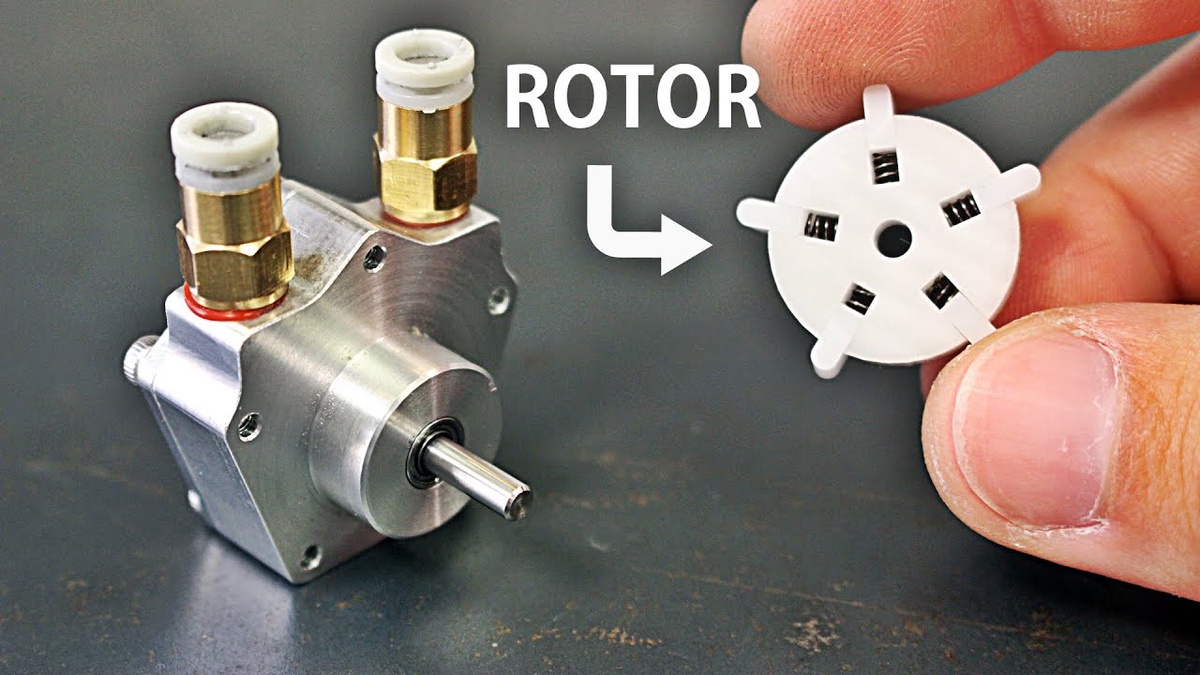

Before diving into maintenance, it's crucial to understand the basic components and operation of your air motor. Air motors use compressed air to generate rotational motion, powering various applications such as pneumatic tools, pumps, and actuators. Depending on the type of air motor—whether it's a vane motor, piston motor, or turbine motor—the maintenance requirements may vary slightly. Familiarize yourself with your specific air motor's manual for detailed maintenance instructions.

Regular Inspection and Cleaning:

Regular inspection and cleaning are fundamental to keeping your air motor in optimal condition. Before each use, visually inspect the motor for any signs of damage, wear, or leaks. Pay close attention to seals, bearings, and moving parts, as these areas are prone to wear over time. Additionally, clean the exterior of the motor regularly to remove dirt, dust, and debris that can affect performance.

Lubrication:

Proper lubrication is crucial for the smooth operation and longevity of your air motor. Refer to the manufacturer's recommendations for the type and frequency of lubrication required for your specific air motor. Apply lubricant to the appropriate points as indicated in the manual, ensuring that the motor remains well-lubricated to reduce friction and wear. Over-lubrication can lead to buildup and performance issues, so be sure to follow the recommended guidelines.

Air Filter Maintenance:

Air quality is essential for the proper functioning of your air motor. Make sure to regularly inspect and clean or replace the air filter according to the manufacturer's recommendations. A clogged or dirty air filter can restrict airflow, leading to reduced performance and potential damage to the motor. Keep the air filter clean and free from debris to maintain optimal air quality and prolong the lifespan of your air motor.

Temperature Control:

Temperature control is critical for air motor performance and longevity, as excessive heat can lead to premature wear and damage. Avoid operating the air motor in extreme temperatures or environments where the motor may be exposed to heat sources or direct sunlight. Additionally, monitor the temperature of the compressed air supply to ensure it remains within the recommended range for your air motor.

Proper Storage:

When not in use, store your air motor in a clean, dry, and well-ventilated environment. Avoid storing the motor in areas prone to moisture, dust, or temperature fluctuations, as these conditions can degrade the motor's components over time. Use protective covers or cases to shield the motor from dust and debris, and ensure that it is stored securely to prevent accidental damage.

Regular Maintenance Schedule:

Establishing a regular maintenance schedule is key to ensuring the longevity of your air motor. Create a checklist of maintenance tasks, including inspection, cleaning, lubrication, and filter replacement, and adhere to it consistently. Depending on the frequency of use and operating conditions, you may need to perform maintenance tasks daily, weekly, or monthly. By staying proactive and disciplined with maintenance, you can catch potential issues early and prevent costly repairs or downtime.

Training and Education:

Invest in proper training and education for yourself and your team members on the operation and maintenance of air motors. Ensure that everyone who operates or works with the air motor understands proper procedures for inspection, cleaning, lubrication, and safety precautions. Regular training sessions and refresher courses can help reinforce good maintenance practices and promote a culture of safety and efficiency in your workplace.

Seek Professional Assistance:

While regular maintenance can help prevent many issues, there may be times when professional assistance is necessary. If you encounter any problems or notice unusual noises, vibrations, or performance issues with your air motor, don't hesitate to seek assistance from a qualified technician or service provider. Prompt attention to maintenance and repairs can help prevent further damage and ensure the continued reliability of your air motor.

Final Thoughts:

In conclusion, proper maintenance is essential for prolonging the lifespan and ensuring the reliable performance of your air motor. By following these maintenance tips and establishing a regular maintenance schedule, you can keep your air motor operating at its best for years to come, maximizing productivity and minimizing downtime in your operations.

No comments yet