You can't overstate the role and importance of cranes in the modern-day construction and industrial sectors. These giant structures of steel and precision stand as the hoisting power of our cities. Since their launch in the 1980s, cranes have continued to assist humans in optimizing material management, transportation, construction, and several types of labor-intensive operations.

In this blog, we’ve particularly talked about the connection between crane equipment and human-machine interfaces. It will help you understand how crane equipment is now more efficient and precise than ever, all thanks to AI, machine learning, and continuous technological advancements.

Cranes: The Architects of Modern Construction

To understand the significance of human-machine collaboration in crane operations, it's imperative to recognize the role of cranes in shaping the modern world.

Cranes have been instrumental in constructing some of humanity's most iconic structures, from towering skyscrapers to intricate bridges. Their evolution has led to the development of modern construction methods, spurring innovation in materials, engineering, and safety protocols.

A Historical Perspective on Crane Equipment and Its Role in Construction Sector’s Growth

Cranes trace their origins back to ancient civilizations, where they were powered by human or animal labor. The Greeks and Romans developed early iterations of cranes to lift heavy stones for their architectural marvels. These primitive cranes laid the foundation for the construction techniques that would later define the construction industry.

The Industrial Revolution in the Construction Sector

The Industrial Revolution in the 18th and 19th centuries brought significant advancements in crane technology. Steam-powered cranes and, later, electric cranes revolutionized construction by providing more power and precision. The ability to lift heavier loads and operate with greater efficiency led to the construction of taller buildings and longer bridges.

The Digital Age of Crane Operations and Its Revolutionary Power

In the digital age, cranes have evolved into highly sophisticated machines equipped with state-of-the-art technology. The fusion of advanced materials, powerful engines, and precise control systems has elevated crane operations to unprecedented levels of precision and safety. However, these advancements also highlight the need for seamless human-machine collaboration to harness the full potential of modern crane technology.

How Do Cranes Bridge the Human-Machine Interfaces Gap?

In today's digital age, crane operations have transitioned from manual controls to advanced human-machine interfaces (HMIs). These interfaces empower operators with real-time data, precise control, and enhanced safety features, revolutionizing the way cranes are operated. Here are some notable HMIs reshaping crane operations:

1. Load Moment Indicators (LMIs) and Rated Capacity Indicators (RCIs)

LMIs and RCIs are instrumental in load management. They provide operators with real-time data on load weight, load radius, and crane stability. Integrated with load charts and safety limits, these systems enable operators to make informed decisions, preventing overloads and ensuring safe lifts.

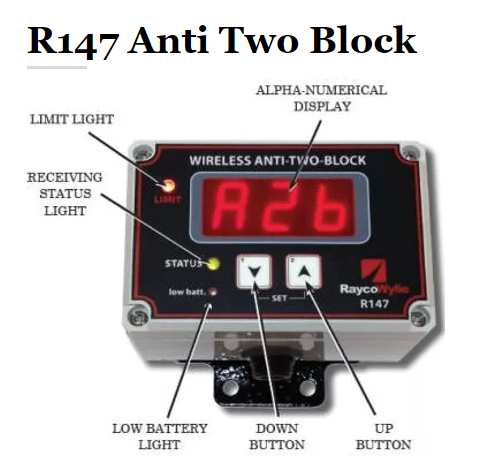

2. Anti-Two Block (ATB) Systems

ATB systems, coupled with HMIs, prevent one of the most hazardous crane conditions: the two-block scenario. When the hook block reaches the boom tip or another component, ATB systems issue warnings or disable the crane to avert accidents.

3. Crane Camera Systems

Intricate crane operations often suffer from limited visibility. Crane camera systems, such as the CCS2 and CCS4, provide operators with comprehensive views of their surroundings. These systems eliminate blind spots, enhancing safety during lifts and maneuvers.

4. Remote Monitoring and Control

Digital interfaces enable remote monitoring and control of crane operations. Supervisors can access real-time data, intervene in emergencies, and optimize crane utilization, all from a safe distance.

5. Sensor Integration

Sensors, including wind speed indicators and load sensors, are seamlessly integrated with HMIs. These sensors provide critical data for safe crane operations, allowing operators to adjust based on environmental conditions and load factors.

6. GPS and Telematics

GPS technology combined with telematics systems offers precise location tracking, route optimization, and real-time alerting. These features are invaluable for large construction sites and complex logistics.

Partner with Crane Warning Systems Atlanta to Boost Your Equipment’s Safety and Robustness

Crane Warning Systems Atlanta offers the most comprehensive suite of crane systems products on the market. Their commitment to excellence and innovation ensures that your construction site is equipped with the best crane warning system available. Don't compromise on safety—choose Crane Warning Systems Atlanta and elevate your crane safety standards today.

Author’s Bio

This post’s author is an experienced and professional crane equipment inspector. He has been associated with OSHA as a technical crane inspection manager and a regular contributor to Crane Warning Systems Atlanta’s website blog section. He loves sharing his knowledge and market insights with crane operators, inspectors, riggers, and spotters.

No comments yet