HP Jet Fusion-Revolutionizing 3D Printing in HP Design and Manufacturing

Introduction:

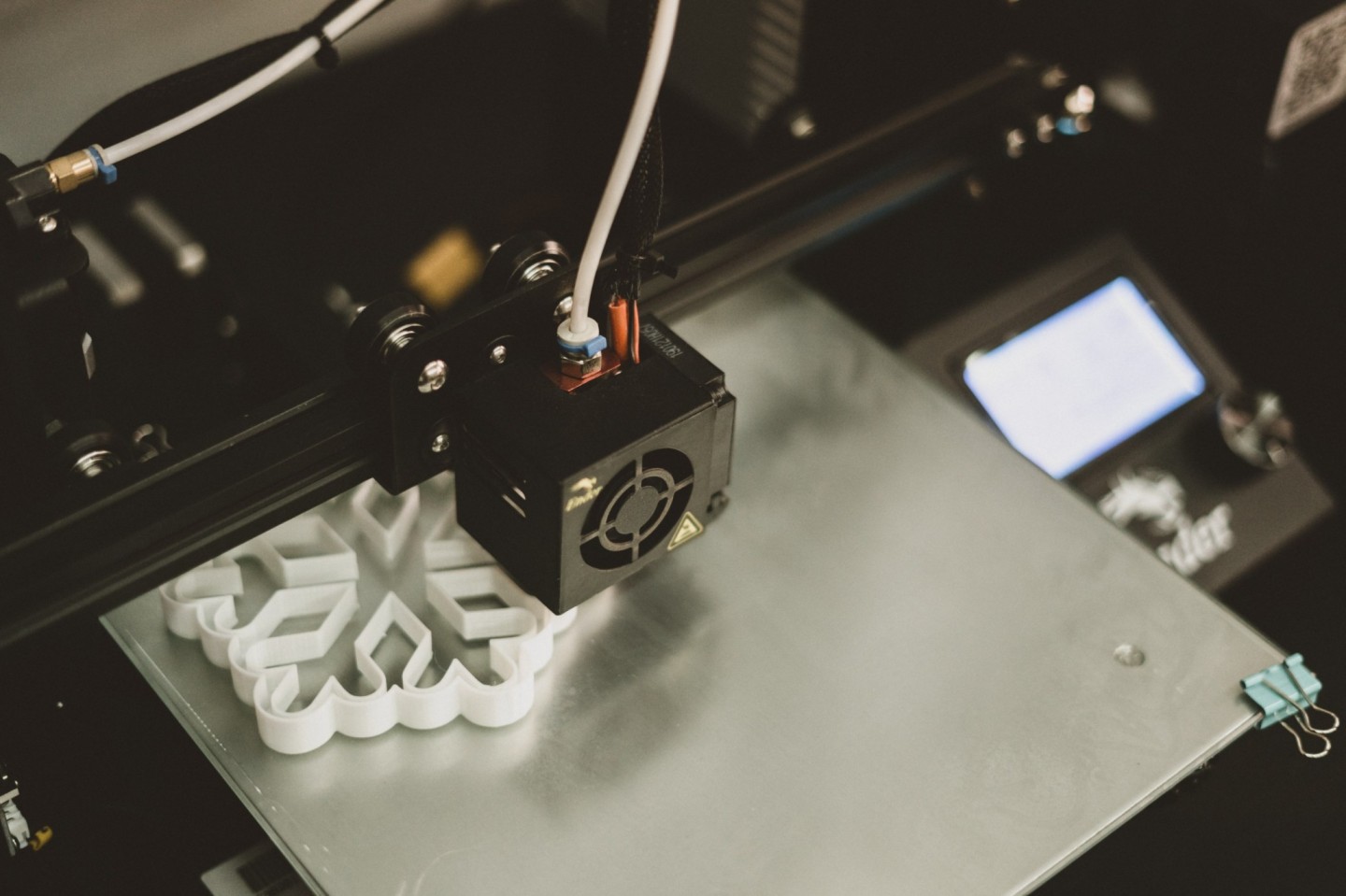

In the ever-evolving landscape of HP design and manufacturing Hewlett-Packard's (HP) Jet Fusion technology stands out as a revolutionary force, redefining the traditional norms of production. This blog explores how HP Jet Fusion is transforming the manufacturing process within the framework of HP design and manufacturing, addressing historical barriers, and unlocking new possibilities for designers and manufacturers alike.

A 3D Printing Revolution:

HP Jet Fusion represents a paradigm shift in manufacturing, challenging century-old practices within the context of HP design and manufacturing. Historically, production processes, from design to manufacturing, have followed a linear path. However, Jet Fusion introduces a disruptive 3D printing solution, breaking free from the constraints of traditional manufacturing and ushering in a new era of flexibility and efficiency within the realm of HP design and manufacturing.

Cost and Quality- Former Barriers to Adoption:

Traditionally, cost and quality have been significant barriers to adopting 3D printing for final part fabrication within the framework of HP design and manufacturing. The perceived flat cost per part and limited production capacity hindered widespread adoption. HP Jet Fusion, with its Multi Jet Fusion technology, shatters these barriers. It introduces a cost-effective solution with enhanced production capacity, making 3D printing a competitive choice for manufacturing within the context of HP design and manufacturing.

Optimizing Design for Jet Fusion:

To fully harness the potential of HP Jet Fusion within the context of HP design and manufacturing, designers need to understand and embrace its unique design guidelines. This involves guiding designers on optimizing their creations for optimal quality and cost-effectiveness. The ability to digitally tune designs to the fabrication process marks a significant departure from traditional, labor-intensive tuning methods within the scope of HP design and manufacturing.

The Proposed Solution:

HP Jet Fusion 3D Printing Solutions offer a roadmap for businesses embarking on their 3D printing journey within the framework of HP design and manufacturing. As software development progresses, the seamless integration of design tools and the Jet Fusion process becomes a key driver for success within HP design and manufacturing.

Approaching the Perfect Storm in Manufacturing:

As the manufacturing landscape undergoes a perfect storm of change, with global competition and hyper-connectivity within the framework of HP design and manufacturing, HP Jet Fusion emerges as a catalyst for success. The technology not only addresses cost and quality concerns but also enables the production of differentiating products through unique designs within the context of HP design and manufacturing. The future promises even more, with Jet Fusion's potential to offer multiple properties within a single object, providing unprecedented versatility in manufacturing.

Conclusion:

In conclusion, HP Jet Fusion transcends the boundaries of traditional manufacturing within the context of HP design and manufacturing, offering a transformative solution that combines cost-effectiveness with unparalleled design flexibility. With the integration of software, optimized design processes, and a commitment to addressing historical barriers within HP design and manufacturing, HP Jet Fusion paves the way for a future where 3D printing becomes synonymous with agile, efficient, and innovative manufacturing. Embracing HP Jet Fusion within the scope of HP design and manufacturing means not just adapting to change but leading the way into a new era of part fabrication.

No comments yet