In the ever-evolving landscape of additive manufacturing, where innovation is the driving force, one name stands out prominently - Igus. With a relentless commitment to advancing the field of 3D printing, Igus has become synonymous with innovation, and its materials are making waves in the industry. In this article, we delve into the world of 3D printing with Igus materials, exploring how these cutting-edge filaments are reshaping the future of additive manufacturing.

The Evolution of 3D Printing

Before we dive into the innovations brought forth by Igus materials, let's take a moment to understand the evolution of 3D printing. Also known as additive manufacturing, 3D printing has come a long way since its inception. Initially, it was limited to prototyping and small-scale projects. However, advancements in technology and material science have grown into a full-fledged industrial revolution.

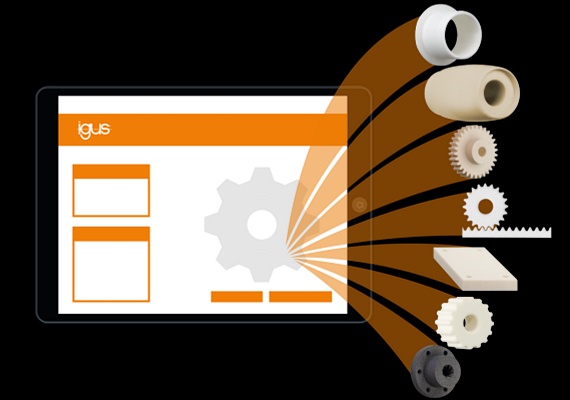

Igus Materials: A Game-Changer in 3D Printing

Igus, with its unwavering commitment to innovation, has introduced a range of materials that are redefining the capabilities of 3D printing. These materials go beyond the conventional, offering unique advantages that open new avenues for additive manufacturing.

- Enhanced Durability

One of the standout features of Igus materials is their exceptional durability. These filaments are engineered to withstand wear and tear, making them ideal for applications. that demand robust and long-lasting components. Whether creating intricate mechanical parts or producing functional prototypes, Igus materials ensure your creations stand the test of time.

- Low Friction Properties

Friction is a common enemy in many mechanical systems. Igus materials are designed to combat this challenge with their low friction properties. This makes them perfect for creating parts in applications where smooth movement and reduced wear are critical.

- Self-Lubricating

Imagine components that resist wear and lubricate themselves during operation. Igus materials bring this innovation to life with their self-lubricating capabilities. This feature reduces maintenance requirements and extends the lifespan of 3D-printed parts, making them an economical choice for various industries.

- Chemical Resistance

In 3D printing, compatibility with various chemicals is paramount. Igus materials excel in this aspect, boasting impressive resistance to various chemicals. This makes them indispensable for industries that deal with corrosive substances, such as the automotive and chemical industries.

Diverse 3D Printing Applications

Igus materials are versatile and find applications across many industries. Their unique properties open doors to countless possibilities, some of which include:

- Automotive Industry

In the automotive sector, precision and durability are non-negotiable. Igus materials offer solutions for producing components like bushings, gears, and brackets that can withstand the rigours of the road while providing impeccable performance. Additionally, their self-lubricating properties reduce maintenance, a significant advantage in the fast-paced automotive world.

- Aerospace and Aviation

In the aerospace and aviation sector, where weight and reliability are of utmost importance, and Igus materials are gaining traction. 3D-printed components using these materials are not only lightweight but also resistant to extreme temperatures, chemicals, and mechanical stresses. This makes them suitable for various critical applications, from engine components to interior fittings.

- Medical Devices

Precision and biocompatibility are paramount in the medical device industry. Igus materials are ideal for 3D printing components such as prosthetic limbs, surgical tools, and customised implants. Their durability and chemical resistance ensure these devices can withstand the demanding healthcare environment.

- Manufacturing and Automation

In manufacturing and automation, where machinery runs round the clock, wear and tear are inevitable. Igus materials come to the rescue by offering self-lubricating properties that reduce friction and extend the life of moving parts. This enhances the efficiency of automated systems and lowers maintenance costs.

The Future of 3D Printing with Igus Materials

As we look ahead, it's clear that Igus Materials will continue to drive innovation in the world of 3D printing. With ongoing research and development, we can anticipate even more groundbreaking advancements. The materials' ability to combine durability, low friction, self-lubrication, and chemical resistance is a cornerstone in the additive manufacturing landscape.

- Customization and Personalization

One exciting aspect of 3D printing is its potential for customisation and personalisation. Igus materials, with their versatility, will play a crucial role in enabling tailored solutions for various industries. Whether creating unique consumer products or highly specialised industrial components, 3D printing with Igus materials will allow for unprecedented customisation.

- Sustainability

In an era where sustainability is paramount, Igus materials are making strides in reducing environmental impact. With their longevity and reduced maintenance requirements, 3D printed parts using Igus materials contribute to a greener future by reducing waste and resource consumption.

- Collaboration and Innovation

The 3D printing community thrives on collaboration and innovation. Igus actively engages with makers, engineers, and designers to push the boundaries of what's possible. Their commitment to open innovation ensures that the 3D printing ecosystem continues to evolve, with new applications and solutions emerging regularly.

In the world of additive manufacturing, Igus materials have emerged as a game-changer. Their exceptional durability, low friction properties, self-lubrication, and chemical resistance make them a go-to choice for various industries. From automotive and aerospace to medical devices and automation, Igus materials are pushing the boundaries of 3D printing.

As we look to the future, Igus materials are poised to lead the way in customisation, sustainability, and collaborative innovation. The world of 3D printing is evolving, and the possibilities are limitless with Igus materials at its core. Embrace the revolution and witness the transformative power of 3D printing with Igus materials in the world of additive manufacturing.

No comments yet