Automotive electronics have evolved remarkably in recent years, with technology playing a pivotal role in enhancing vehicle performance, safety, and efficiency. One of the key innovations contributing to these advancements is the integration of Rigid-Flex PCBs (Printed Circuit Boards) in automotive electronic systems. Let's explore the significance of rigid-flex PCBs in the automotive industry, including their applications, benefits, and impact on vehicle design and functionality.

Navigating Rigid-Flex PCBs

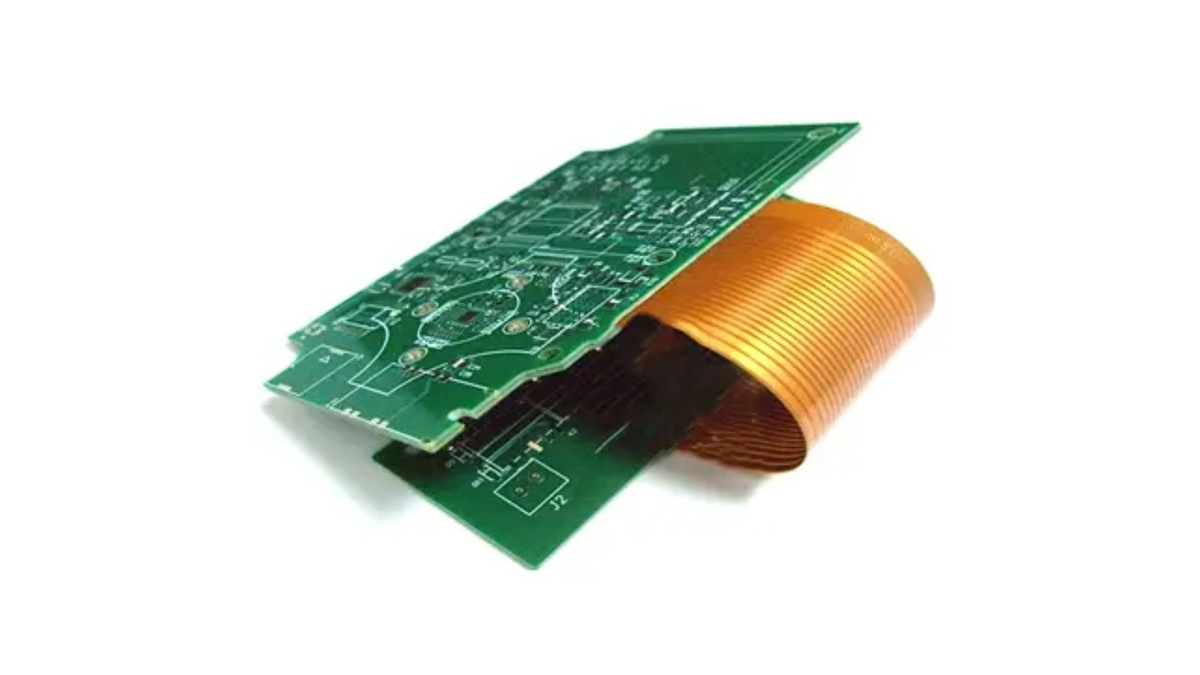

- Rigid-Flex PCB Board: Rigid-Flex PCBs are hybrid circuit boards that combine both rigid and flexible board technologies. These boards consist of myriad layers of flexible circuit substrates related to one or more rigid boards. This unique design allows for three-dimensional configurations, enabling electronic components to be interconnected seamlessly.

- Flex-Rigid PCB: A subset of Rigid-Flex PCBs, Flex-Rigid PCBs are characterized by their aptitude to bend and fold without compromising structural integrity. This flexibility is particularly advantageous in applications where space constraints and complex designs demand a more adaptable circuitry solution.

Applications in Automotive Electronics

- In-Car Infotainment Systems: Rigid-flex PCBs play an important role in developing in-car infotainment systems. The flexible nature of these boards allows for easy integration into the curved surfaces of modern vehicle interiors, facilitating the creation of sleek and aesthetically pleasing multimedia interfaces. Additionally, their compact design contributes to space optimization within the limited confines of a vehicle's dashboard.

- Advanced Driver Assistance Systems (ADAS): The automotive industry's shift towards autonomous driving and enhanced safety features has increased the reliance on ADAS. Rigid-flex PCBs enable the seamless integration of sensors, cameras, and radar systems necessary for ADAS functionality. The flexibility of these boards accommodates the diverse shapes and contours of modern vehicle exteriors, ensuring optimal sensor placement for reliable performance.

- Engine Control Units (ECUs) and Power Management: Efficient power distribution and management are critical in modern vehicles. Rigid-flex PCBs find applications in Engine Control Units, managing the complex network of sensors and actuators that regulate engine performance. Their compact design aids in minimizing signal interference and optimizing the layout of power circuits, enhancing overall vehicle efficiency.

Benefits of Rigid-Flex PCBs in Automotive Applications

- Space and Weight Savings: Traditional rigid boards and interconnecting cables can occupy a significant amount of space within a vehicle. With their streamlined design, Rigid-Flex PCBs eliminate the need for multiple connectors and cables, leading to space savings and reduced weight. This is particularly advantageous in electric vehicles, where weight reduction improves energy efficiency.

- Reliability and Durability: Automotive environments pose challenges such as vibrations, temperature variations, and exposure to moisture. Rigid-flex PCBs, designed with materials resistant to these factors, exhibit enhanced reliability and durability. This ensures the longevity of electronic components, reducing the likelihood of system failures and minimizing maintenance requirements.

- Design Flexibility: The flexibility of Rigid-Flex PCBs allows for intricate and compact designs, catering to the evolving aesthetic and functional requirements of modern vehicles. This adaptability is especially valuable in electric and hybrid vehicles, where unconventional shapes and configurations are increasingly common.

The Future of Rigid-Flex PCBs in Automotive Electronics

As automotive tech continues to advance, the role of Rigid-Flex PCBs is expected to grow. The continuous development of electric and autonomous vehicles will demand even more sophisticated and compact electronic systems, further emphasizing the benefits of Rigid-Flex PCBs in optimizing space, weight, and functionality.

The Final WORDS

Rigid-flex PCBs are integral to the evolution of automotive electronics, offering a versatile solution to the complex design challenges posed by modern vehicles. From in-car infotainment to advanced driver assistance systems and power management, the applications of Rigid-Flex PCBs are diverse and impactful. As automotive technology progresses, these innovative circuit boards will continue to play an essential part in shaping the future of electronic systems in the automotive industry!

No comments yet