PLCs from Allen-Bradley are essential components of industrial automation and control systems. The input and output devices that these PLCs connect with include sensors, switches, motors, valves, and other field devices. PLCs communicate with these components to collect real-time data from industrial processes and provide instructions to control various parts of the activities.

- I/O Modules:

Input/output (I/O) modules are a requirement for any Allen Bradley PLC system since they act as the interface between the PLC and field devices like sensors, actuators, and other control gear. Some of the most well-liked I/O modules for Allen Bradley PLCs are listed below:

- Digital Input Modules:

A few examples of the digital field devices with which these modules interact are push buttons, limit switches, and sensors. They convert the input signals from these devices into digital signals that the PLC can process.

Push buttons, limit switches, and sensors are examples of digital field devices that are interfaced with using digital input modules. They transform the input signals from these gadgets into digital signals so that the Allen Bradley PLC can process them.

- Digital Output Modules:

These modules may control a variety of digital output devices, including relays, solenoids, and indicators. They receive digital signals from the PLC and convert them into output signals so that they can operate the output devices.

Relays, solenoids, and indicators are examples of digital output devices that are controlled by digital output modules. The Allen Bradley PLC sends digital signals to them, which they then transform into output signals that can control the output devices.

- Analog Input Modules:

The connections to analogue field equipment including flow metres, pressure sensors, and temperature sensors are made using these modules. These devices convert the analogue input signals into digital signals that the PLC can process.

To connect to analogue field equipment including temperature sensors, pressure sensors, and flow metres, analogue input modules are employed. They transform the analogue input signals from these gadgets into digital signals that the Allen Bradley PLC can process.

- Analog Output Modules:

These modules are used to control analogue output actuators, motors, and valves. They accept digital signals from the PLC and convert them into analogue output signals that can be used to operate the output devices.

Examples of analogue output devices that are managed by analogue output modules include valves, motors, and heaters. They transform the digital signals they receive from the Allen Bradley PLC into analogue output signals in order to control the output devices.

- Communication Modules:

The interface between numerous systems, including SCADA, DCS, and HMIs, is made up of these components. They serve as these systems' interfaces for communication with the PLC, allowing for the transfer of data and the alteration of system settings.

When updating an older Allen Bradley PLC system, it's crucial to confirm that the new platform is compatible with the I/O modules already in place, or to make plans to upgrade these parts concurrently with the upgrade. In order to make sure that the new I/O modules can satisfy these objectives, it is also crucial to assess the system's existing and future I/O requirements. Using communication modules, you can connect to other systems like SCADA, DCS, and HMIs.

Check :- Allen Bradley 1766-L32BWAA MicroLogix 1400 PLC

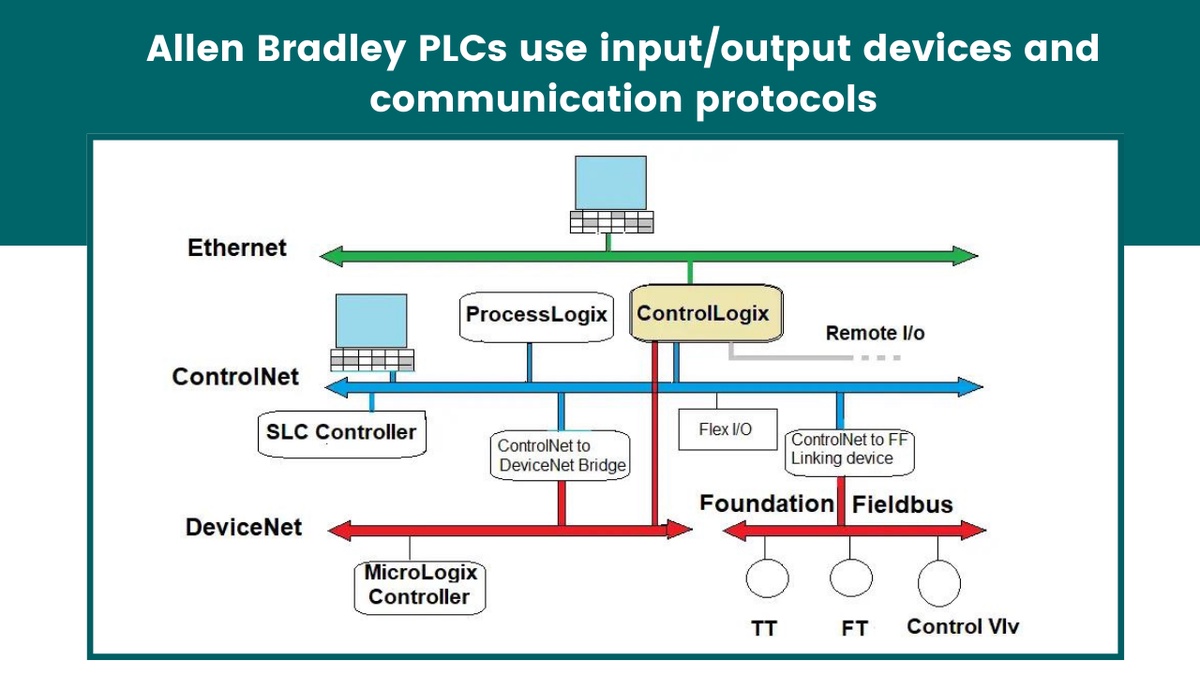

- Communication Protocols:

- Ethernet/IP:

a popular protocol for real-time device control and communication on Ethernet networks

A common communication protocol used by Allen Bradley PLCs and other industrial automation and control systems is Ethernet/IP. Ethernet/IP is based on traditional Ethernet technology and uses the Internet Protocol (IP) to transport data between devices on an Ethernet network.

A variety of communication services are provided by Ethernet/IP, including messaging services for real-time data transmission, data exchange services for block data transfers, and configuration services for configuring networks and devices.

- ControlNet:

a high-speed, deterministic, and fault-tolerant protocol used for connecting PLCs, I/O devices, and other industrial equipment

The company that makes Allen Bradley PLCs, Rockwell Automation, created the proprietary communication protocol called ControlNet. ControlNet is made to offer deterministic, high-speed communication between PLCs, HMIs, and I/O modules, among other types of control devices.

A multi-drop bus topology is used by ControlNet to enable the sharing of a single communication channel by numerous devices. This topology is suitable for real-time control applications because it offers fast communication and deterministic behavior.

- DeviceNet:

a low-cost, user-friendly protocol used in distributed control systems to link sensors, actuators, and other devices

DeviceNet is a communication protocol developed by Rockwell Automation, the manufacturer of Allen Bradley PLCs. DeviceNet was developed to link field equipment, such as sensors, actuators, and I/O modules, to control systems. It provides a simple and cost-effective communication option.

DeviceNet permits the sharing of a single communication channel by many devices through the use of a bus topology. This topology provides a viable cost-saving technique for connecting field equipment by reducing the quantity of cabling required.

- Profibus: a popular protocol for coordinating automation systems, gadgets, and control parts

It is crucial to check that the new platform can communicate with the legacy Allen Bradley PLC system's I/O modules and communication protocols, or to prepare for their upgrade as part of the upgrade process.

PLCs are capable of monitoring, controlling, and optimising intricate industrial processes by smoothly combining input/output devices and communication protocols. Input devices provide the PLC instantaneous insights into process factors, enabling it to make wise judgements.

Asteam Techno Solutions Pvt. Ltd. has boasts over 10 years of experience in the industrial sector, founded in India and then became one of the best industrial automation parts supplier in India as well as globally. We provide automation solutions with reputed brands including Allen Bradley, Mitsubishi, Phoenix Contact, Siemens, Schneider, Moxa, VIPA and more.

No comments yet