The semiconductor industry is a key player in the modern technological era, pivotal to the digital infrastructure that underpins everything from smartphones to advanced computing systems. However, it faces considerable challenges in maintaining and enhancing production yields, particularly amid skyrocketing global demand. The industry finds itself under pressure to find solutions to these challenges, chiefly driven by the threat that yields issues posed to the sustainability of businesses in this sector. This blog post delves into the intricate layers of the semiconductor manufacturing process, and the pivotal role of emerging technologies in improving yields, and offers a comprehensive perspective into the future trajectory of semiconductor data production.

Semiconductor Manufacturing: A Complex Affair

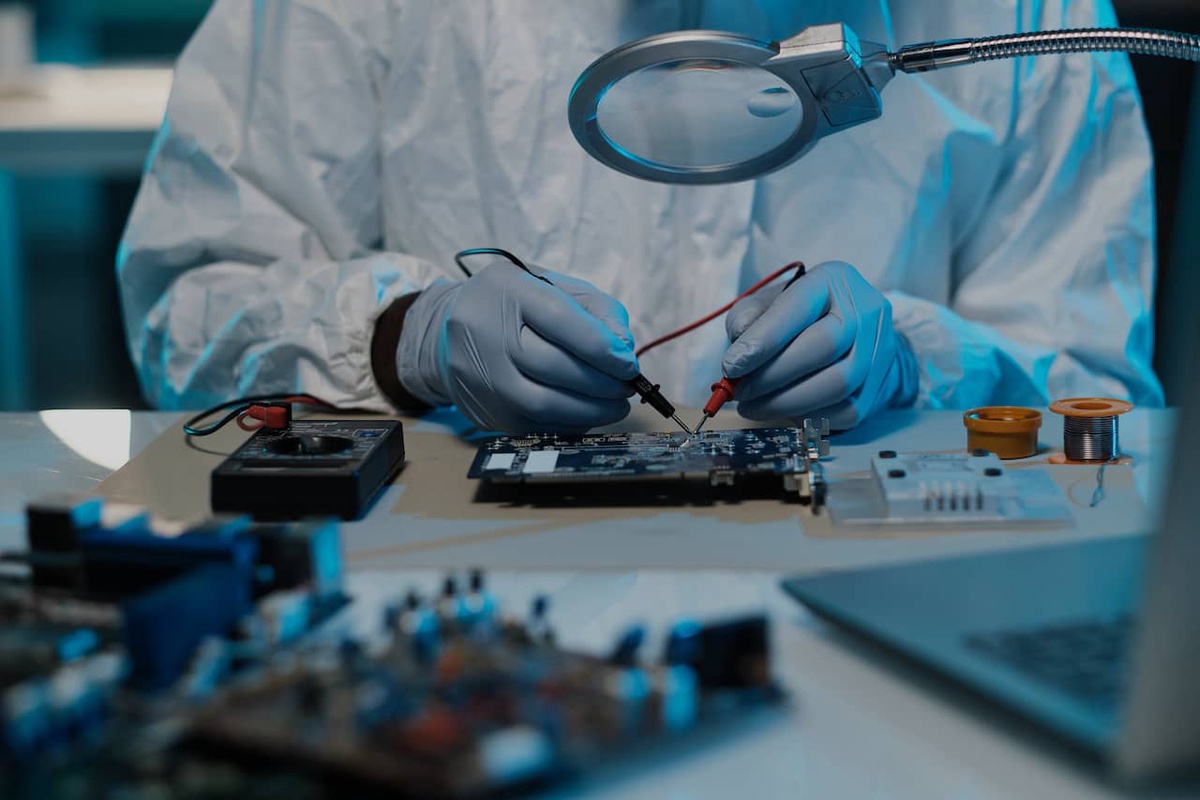

Semiconductor manufacturing is far from a simple process. It involves hundreds of high-precision steps, each of which is critical to the final product's yield and quality. Each step must be carried out with utmost precision to ensure the overall yield is maintained. This complexity is further compounded by the continuous need for design and fabrication improvements, necessitated by the rapid pace of technological advancements.

Falling below the industry's benchmark yield rate of 90% can lead to significant economic impacts. In this environment, it becomes increasingly essential for the sector to adopt advanced technologies such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT), which have the potential to mitigate these challenges and propel yield improvement.

Digitizing Supply Chains for Optimized Production

In the drive to enhance efficiency and boost yields, the industry has turned its attention to end-to-end digitization of supply chains. By leveraging AI/ML and IoT devices, manufacturers have an opportunity to optimize production processes and minimize timing gaps between different steps, thereby boosting overall yields. A fully digitized oee supply chain goes beyond mere process optimization—it provides complete visibility into every stage of the process, from raw materials to the finished product. This level of visibility fosters a culture of data-driven decision-making, enhancing overall yield and driving profitability.

Predictive Maintenance and Digital Twins

To ensure smooth, uninterrupted operations, AI and ML are employed in predictive maintenance, alerting manufacturers to potential equipment failures before they occur. This predictive capability increases machine uptime and contributes significantly to improved yield. In addition, manufacturers are creating digital twins of their manufacturing operations and supply chain reliability. These digital twins serve as a virtual representation of the entire production ecosystem, connecting all stakeholders and assets, providing data for improved efficiency, and offering actionable insights that can lead to yield optimization.

Cognitive Processing and the Manufacturing Value Chain

AI's role in the semiconductor industry goes far beyond maintenance and monitoring. One of the most significant benefits of AI integration is cognitive processing – the incorporation of AI throughout the entire manufacturing value chain. Cognitive processing assists with product lifecycle management, addressing a range of challenges, including the handling and analysis of vast amounts of manufacturing data using data analysis tool, asset maintenance and repair, quality control, resource optimization, and reliability in supply chain management. This intelligent processing capability can identify inefficiencies, suggest improvements, and enable preemptive measures to enhance yield and productivity.

The Role of AR/VR in Enhancing Manufacturing Operations

The potential of augmented reality (AR) and virtual reality (VR) is now being harnessed in the semiconductor industry. By creating immersive digital twins, AR and VR can enhance manufacturing and supply chain operations, leading to improved efficiency and yield. AR, in particular, can overlay real-time data onto real-world objects, greatly enhancing tasks like product and process design, data and yield analytics, quality assurance, diagnostics and maintenance, order picking in warehouses, inventory management, and workforce collaboration. This immersive technology revolutionizes the way work is carried out, improving speed, accuracy, and ultimately, yield.

Understanding Yield Loss Mechanisms

As part of the drive to improve yields, understanding yield loss mechanisms is crucial. AI and ML technologies can parse through vast amounts of data, identifying patterns, trends, and anomalies that give a granular view of the sources of yield loss. With this insight, manufacturers can develop a robust framework to detect and mitigate yield loss effectively. This targeted approach is key to boosting yield rates and maintaining the economic viability of manufacturing operations.

Advanced Analytics for Enhanced Manufacturing Yield

Advanced analytics, supported by AI and ML, can facilitate real-time monitoring and control of production processes. Machine learning models can be trained to provide predictive analytics in semiconductor manufacturing, offering insights into potential issues before they impact yield. This seamless integration of technologies enables the creation of a "smart factory" environment where all components of the manufacturing ecosystem can communicate and make autonomous decisions, contributing to yield optimization.

Executive Dashboard Reporting for Improved Yield Management

To enable effective yield management, executive dashboard reporting is implemented. It provides a clear and concise overview of key performance indicators (KPIs), crucial metrics, and other important data points relevant to the production process. These interactive dashboards allow top executives and stakeholders to quickly assess the performance of various production units, identify trends, and make informed decisions. By providing a high-level view of operations, it allows for rapid response to changes, contributing to improved yield and operational efficiency.

Conclusion

The adoption of a human-centric approach to technology is vital for ensuring the maximum effectiveness of these emerging technologies and for driving profit growth. Such an approach facilitates smoother adoption of technologies like AI/ML, IoT, and AR/VR and ensures that the semiconductor industry continues to evolve and thrive amidst increasing global demand and rapid technological advancements. The future of semiconductor manufacturing is an exciting blend of people and technology, working seamlessly to meet the demands of a rapidly evolving world. The journey towards improving yields and sustaining growth is ongoing, and with the right technology and strategies, the semiconductor industry can look forward to a future of unparalleled innovation and success.

References:

- "Improving Production Yield in the Semiconductor Industry." https://www.infosys.com/digital/radar/assets/pdfs/improving-production-yield-in-the-semiconductor-industry.pdf

- "AI and Machine Learning in Semiconductor Manufacturing: The Rise of Computational Process Control." https://www.intechopen.com/chapters/62670

- "Transforming Manufacturing With AI and IoT." https://www.forbes.com/sites/forbestechcouncil/2020/12/10/transforming-manufacturing-with-ai-and-iot/?sh=6ab83ef813d0

- "Digital Twin: Manufacturing Excellence through Virtual Factory Replication." https://www.arenasolutions.com/resources/articles/digital-twin/

- "Yield Analysis and Optimization." https://www.eetimes.com/why-yield-analysis-and-optimization-is-critical-in-semi-manufacturing/

- "Process Variability and Its Impact on Semiconductor Device Yield." https://www.researchgate.net/publication/324968735_Process_Variability_and_Its_Impact_on_Semiconductor_Device_Yield

- "Enabling Smart Manufacturing with Edge AI." https://ieeexplore.ieee.org/document/9031419

- "Dashboards for Manufacturing." https://www.klipfolio.com/solutions/manufacturing-dashboards

No comments yet