Efficiency is the lifeblood of industries, impacting productivity, sustainability, and cost-effectiveness. Whether in aerospace, electronics, material science, or the energy sector, the quest for efficiency drives innovation. Thermal analysis emerges as a key player in achieving and maintaining efficiency standards.

This analytical approach is a crucial scientific discipline that delves into the study of material properties as they respond to temperature changes. It assumes a central role across diverse industries, guiding processes to achieve optimal efficiency and performance.

In this article, we will explore the fundamental importance of this analytical method in optimizing efficiency across diverse industries, delving into key features that make it an indispensable tool.

What are the key features of thermal analysis?

Here are the key features of this analytical method:

-

Sensitivity to Temperature Changes

This analysis approach is prized for its sensitivity to temperature variations, providing insights into how materials respond under different thermal conditions. Whether a material becomes brittle, ductile, or undergoes phase transitions, understanding these changes is fundamental for optimizing processes.

In metallurgy, for instance, the tempering of steel relies on precise analysis. The transformation of the material's structure at specific temperatures ensures desired mechanical properties, reinforcing the critical role of thermal sensitivity.

-

Precision in Measurement

The modern analytical approach employs sophisticated instruments capable of precise temperature measurement. Differential Scanning Calorimeters (DSC) and Thermogravimetric Analyzers (TGA) provide accurate data, enabling scientists and engineers to make informed decisions based on real-time thermal data.

In industries like pharmaceuticals, where temperature control is paramount, this approach ensures the production of consistent and high-quality products. The precision in measurement contributes to the optimization of manufacturing processes, reducing waste and enhancing overall efficiency.

-

Heat Capacity Analysis

Heat capacity analysis is integral to comprehending how materials store and release heat. This understanding is crucial in designing energy-efficient systems and products. Materials with high heat capacity can absorb and release large amounts of energy, influencing their suitability for specific applications.

In architecture, the analysis of building materials' heat capacity aids in designing energy-efficient structures. The capacity of materials to control temperature variations aids in diminishing energy usage for heating and cooling in harmony with global sustainability targets.

-

Thermal Conductivity Insights

Thermal conductivity analysis provides insights into a material's ability to conduct heat. This property is vital in various applications, from electronics to construction. Materials exhibiting high thermal conductivity enable effective dissipation of heat, preventing overheating and ensuring optimal performance.

In the automotive industry, thermal conductivity analysis guides the selection of materials for engine components. Efficient heat transfer properties contribute to enhanced engine performance, fuel efficiency, and overall reliability.

-

Real-time Monitoring

One of the distinctive features of this analytical approach is its ability to monitor processes in real-time. This continuous analysis is particularly valuable for dynamic systems where temperature changes occur rapidly. Real-time monitoring allows for immediate adjustments, preventing inefficiencies and ensuring optimal performance.

Industries with dynamic processes, such as chemical manufacturing, benefit from real-time thermal testing to make proactive adjustments. Identifying and addressing potential issues in advance enables companies to minimize downtime, lower energy consumption, and boost overall operational efficiency.

Applications in Different Industries

Here are the applications of thermal analysis in various industries:

-

Aerospace

Aerospace engineering relies heavily on this analytical strategy to guarantee the safety and effectiveness of aircraft. Understanding heat distribution and dissipation is critical for preventing overheating of components, ensuring fuel efficiency, and maintaining structural integrity under extreme conditions.

-

Electronics

In the electronics industry, this strategy is indispensable for managing heat generated by electronic components. Efficient heat dissipation is crucial for preventing overheating, which can degrade performance and lead to premature component failure.

By optimizing the thermal design of electronic devices, manufacturers enhance overall system performance. The analysis strategy guides the selection of materials and cooling solutions, contributing to the development of reliable and high-performance electronic products.

-

Material Science

Material scientists leverage this analytical approach to innovate and develop new materials with desired thermal properties. Whether for medical implants or sustainable packaging, understanding how materials respond to temperature changes is essential for pushing the boundaries of material science.

The quest for sustainable materials involves analyzing their thermal properties. Materials designed with a focus on thermal efficiency contribute to energy conservation and environmental sustainability, aligning with global initiatives for a greener future.

-

Energy Sector

In the energy sector, it is instrumental in optimizing power generation processes. Power plants benefit from insights into heat transfer and storage, improving overall thermal efficiency and reducing environmental impact.

The development of renewable energy technologies, such as solar panels and wind turbines, relies on this analysis method. Understanding how materials respond to varying temperatures enhances the efficiency of these technologies, making them more viable and competitive in the energy landscape.

What are the future trends and innovations?

-

Evolving Technologies

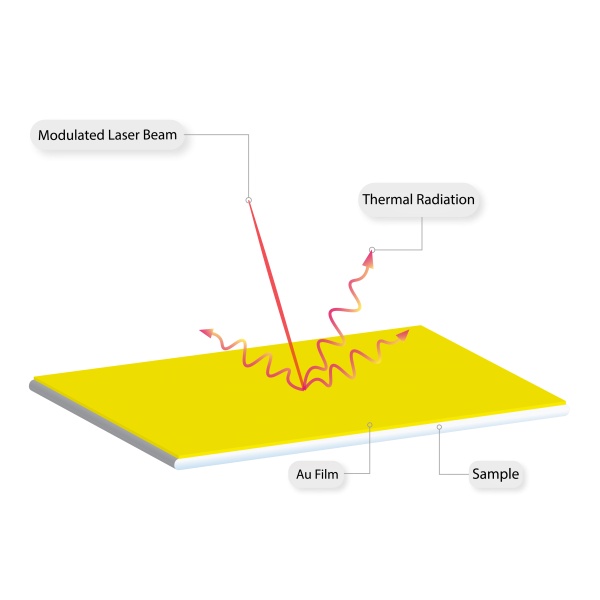

As technology advances, new tools for thermal analysis continue to emerge. Infrared thermography, for example, offers non-contact temperature measurement, opening new possibilities for understanding thermal dynamics in complex systems.

The integration of advanced tools promises improvements in efficiency across industries. From more accurate predictions in material behavior to enhanced process optimization, evolving technologies in this analytical approach pave the way for unprecedented levels of efficiency.

-

Integration with Artificial Intelligence

The synergy between this analytical method and artificial intelligence (AI) is a game-changer. AI algorithms excel in processing immense datasets of thermal information, uncovering patterns and correlations that may go unnoticed in human analysis. This results in heightened precision in predictions and a more profound comprehension of intricate thermal systems.

With the integration of AI, the potential for autonomous efficiency enhancements becomes apparent. Systems equipped with AI-driven thermal testing can adapt in real-time, making continuous improvements without human intervention. This heralds a new era in efficiency optimization.

Conclusion

In conclusion, thermal analysis stands as a cornerstone in the pursuit of efficiency across diverse industries. Its sensitivity to temperature changes, precision in measurement, insights into heat capacity and conductivity, real-time monitoring capabilities, and applications in various sectors make it an indispensable tool. As we look to the future, the integration of evolving technologies and artificial intelligence in this analytical approach promises even greater strides in efficiency, paving the way for a more sustainable and technologically advanced world.

No comments yet