Plating is a process that adds a layer of metal to a product. This process can be used to protect a product, to give it a brighter appearance, or to make a product stronger. The process can be used on many different types of metals, including silver, bronze, gold, and brass. It is used on both new and used products. Some of the most common uses include automotive applications, and medical devices.

Processes used

Plating is a chemical process that deposits metal particles on an item to make it more desirable and improve the properties of the metal. Tin is a non-toxic and non-corrosive metal that can be used to increase the surface thickness and conductivity of metal parts. It is used for a variety of applications including food containers, electrical machinery parts, and other packaging. There are four basic electrolytic plating processes that can be used for tin deposits.

During tin plating, the surface is etched in order to maximize tin deposition. This process is typically performed at a temperature of 70 to 90 deg C. The process is contact free and is also more environmentally friendly. However, it is important to maintain proper control of the anode in order to avoid rough, porous deposits.

To ensure proper tin deposition, the strip must be cleaned to remove dirt and other contaminants. It must also be pickled to remove oxide layers. The pickling process also leaves the surface etched to improve tin deposition.

Common uses

Several industries rely on tin plating, including electronics, food processing, and chemical manufacturing. Tin is one of the most inexpensive metals available, making it a popular choice for manufacturers.

Tin plating can produce a tin surface that has excellent corrosion protection, solderability, and ductility. The surface can be used in almost any industrial application. Its surface has good layer thickness distribution, and it is self-lubricating.

Tin alloys are used to plate iron and steel parts. They are soft, but can be deposited and reflowed to produce a shiny, bright finish. They are often used to protect ferrous metals from corrosion, and they can be used for functional and decorative purposes. They are also used in solar and food processing industries.

In the electronics industry, tin plating is often used to coat wires. The alloys used in the process provide excellent conductivity, and they are also resistant to corrosion. A thin tin layer can also be layered with other layers to increase its corrosion resistance.

Safety considerations

Whether you’re using tin as a plating material or a food packaging material, there are important safety considerations to keep in mind. Tin is an extremely conductive metal, making it a good choice for soldering applications. However, it also carries a number of hazards.

One of the main concerns with tin plating is that it can form tin whiskers. These microscopic metal fibers can cause electrical failures. Fortunately, there are ways to mitigate this problem.

While there is no proven way to avoid tin whiskers, there are mitigation strategies that can be applied. One is to avoid using pure tin. Another is to use tin-lead alloy solder. These alloys are not as susceptible to whisker growth as pure tin.

The electronics industry has been looking to significantly reduce lead and has turned to tin-compounds as the first low-cost replacement. However, further research is needed to understand how tin whiskers form and how to avoid them.

Production methods

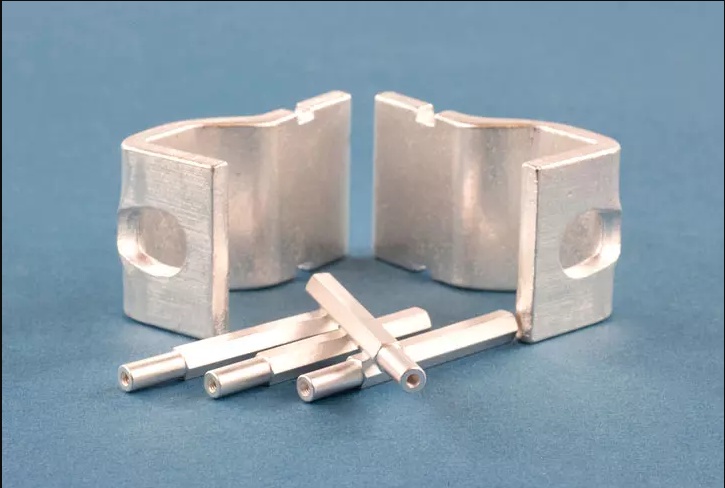

Plating of tin has a number of uses in the chemical and electrical manufacturing industry. It can produce a matte, silver or shiny finish on an object. It provides protection against corrosion and rust. It also has a high level of solderability and ductility. It is used in electrical contacts, connectors, circuit boards and machine components.

Tin plating can be accomplished using one of three methods: tin electroplating, tin plating, or tin dipping. These processes vary according to the type of part being plated, its configuration, and the customer’s specifications.

Tin electroplating is an electrolytic process that deposits a thin layer of tin on a metal object. It is a low-cost, environmentally-friendly process that has a high level of solderability. The process is controlled by the concentration of the plating solution. The concentration of the solution is adjusted to match the temperature of the object being plated. The solution contains an alloying metal compound that provides the metal in soluble form. This compound can be nickel, copper, or cobalt.

No comments yet