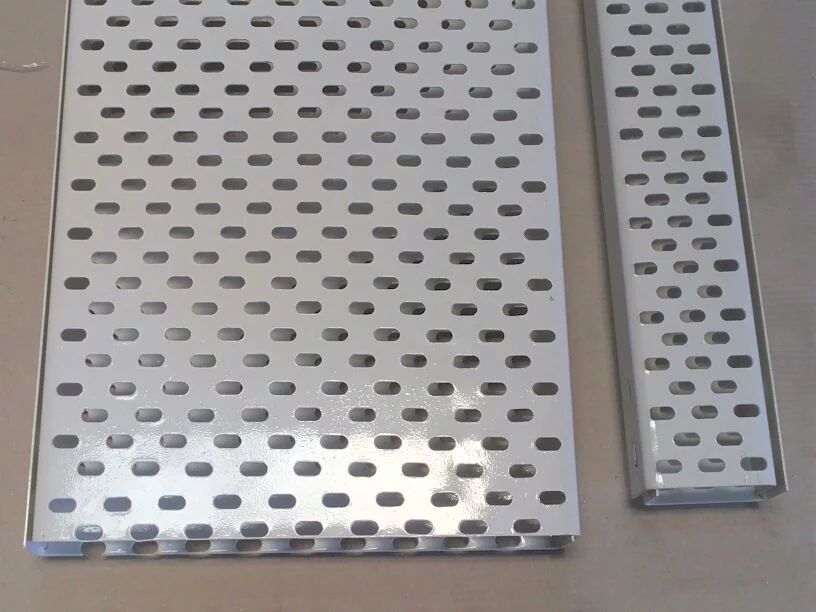

Benefits Of Perforated Cable Trays

A perforated cable tray manufacturer plays a crucial role in the field of electrical and networking infrastructure. Perforated Cable Tray Manufacturer in India is essential components used for the management and support of cables in various industries and commercial buildings. The significance of a perforated cable tray manufacturer lies in several key aspects:

Cable Management:

Perforated cable trays are designed to organize and support cables effectively. They provide a structured system for routing and securing cables, preventing them from becoming tangled or damaged. The manufacturer ensures that the trays are engineered to meet industry standards and specific project requirements, allowing for efficient cable management.

Air Circulation:

The perforations in cable trays serve a vital purpose in maintaining proper air circulation around the cables. Adequate ventilation is essential to dissipate heat generated by the cables, especially in data centers and industrial settings where large amounts of data are processed. A perforated cable tray manufacturer ensures that the trays are designed to promote optimal airflow, helping to prevent overheating and ensuring the longevity of the cables.

Corrosion Resistance:

Manufacturing perforated cable trays with materials that resist corrosion is crucial, especially in environments where exposure to moisture or harsh chemicals is a concern. The manufacturer selects materials and employs coating techniques that enhance the trays' durability and resistance to corrosion, ensuring a longer lifespan and reduced maintenance requirements.

Compliance with Standards:

Cable tray systems must comply with industry standards and regulations to ensure safety and reliability. A reputable manufacturer is responsible for producing trays that meet or exceed these standards, providing assurance to engineers, contractors, and end-users that the cable management system is reliable and safe.

Customization and Flexibility:

Different projects may require unique cable management solutions. A perforated cable tray manufacturer offers a range of customization options to meet the specific needs of a project. This flexibility ensures that the cable trays can adapt to the layout and requirements of different installations, promoting efficiency and ease of installation.

Cost-Effectiveness:

By producing high-quality perforated cable trays that are durable and require minimal maintenance, the manufacturer contributes to the overall cost-effectiveness of a project. The longevity and reliability of the cable tray system reduce the need for frequent replacements or repairs, resulting in long-term cost savings for the end-user.

In conclusion, the significance of a perforated cable tray manufacturer lies in its contribution to efficient cable management, heat dissipation, and corrosion resistance, compliance with standards, customization options, and overall cost-effectiveness. These factors make the manufacturer a crucial partner in the design and implementation of reliable electrical and networking infrastructure systems.

Reasons Why Industry Use Ladder Cable Tray

Ladder cable trays have become an integral component in various industrial settings, offering a reliable and efficient solution for managing and supporting cables. These structures consist of a series of side rails connected by rungs, forming a ladder-like configuration. The choice to implement ladder Cable Trays in industrial environments is driven by several practical and advantageous reasons.

Cable Support and Organization:

Ladder cable trays provide a systematic framework for supporting and organizing cables. The open design allows for easy placement and removal of cables, facilitating efficient maintenance and troubleshooting processes. This organized approach minimizes the risk of cable damage and ensures a tidy and accessible cable management system.

Ventilation and Heat Dissipation:

The open structure of ladder cable trays allows for improved ventilation around the cables. This is crucial in industrial settings where numerous electronic devices and machinery generate heat. Efficient ventilation helps dissipate heat, preventing cables from overheating and ensuring the longevity of both cables and connected equipment.

Accessibility for Maintenance:

The design of ladder cable trays makes them easily accessible for maintenance personnel. Technicians can quickly inspect, repair, or replace cables without the need for extensive disassembly. This accessibility contributes to minimizing downtime and enhancing the overall efficiency of industrial operations.

Adaptability to Varied Environments:

Ladder cable trays are versatile and can be adapted to fit various environmental conditions. They are suitable for indoor and outdoor use and can withstand harsh industrial environments, including exposure to chemicals, extreme temperatures, and other challenging conditions. This adaptability makes them a preferred choice in diverse industries.

Cost-Effectiveness:

Implementing ladder cable trays is often a cost-effective solution for cable management. The simplicity of the design, ease of installation, and reduced maintenance requirements contribute to overall cost savings for industries. Additionally, the durability of these trays ensures a long lifespan, further enhancing their cost-effectiveness.

Scalability and Expansion:

Industries are dynamic, and their infrastructure requirements may change over time. Ladder cable trays offer scalability, allowing for easy modifications and expansions. As the need for additional cables arises, the existing tray system can be extended or reconfigured without significant disruptions to ongoing operations.

Compliance with Safety Standards:

Ladder cable trays are designed with safety in mind. A leading Ladder Cable Tray Manufacturer help in preventing cable entanglement, reducing the risk of electrical hazards and fire incidents. The adherence to safety standards is crucial in industrial environments, making ladder cable trays a preferred choice to ensure a secure and compliant cable management system.

In conclusion, the utilization of ladder cable trays in industries is driven by a combination of factors ranging from cable organization and accessibility to ventilation, adaptability, cost-effectiveness, and safety compliance. These trays play a pivotal role in ensuring the reliability and efficiency of industrial operations, making them a preferred choice for cable management solutions.

No comments yet