Introduction

In the realm of modern technology, the importance of precise and reliable measurement techniques cannot be overstated. Among the various methods employed, capacitive measurement stands out as a versatile and efficient means of gauging parameters in a wide array of applications. In this blog post, we will delve into the intricacies of capacitive measurement, exploring its principles, applications, and the role it plays in advancing industries.

Understanding Capacitive Measurement

At its core, capacitive measurement relies on the principles of capacitance, an electrical property that manifests itself when two conductive objects are separated by a non-conductive material, often referred to as a dielectric. The capacitor formed by these elements stores electrical energy, and changes in capacitance can be correlated with alterations in the physical or environmental factors affecting the capacitor.

Principles of Capacitive Measurement

The fundamental concept behind capacitive measurement lies in the relationship between capacitance, charge, and voltage. As the distance between the two conductive surfaces changes, the capacitance also changes, leading to variations in the amount of charge the capacitor can store. By measuring these changes in capacitance, it becomes possible to infer alterations in the parameters being monitored.

The Capacitive Sensor: A Key Player

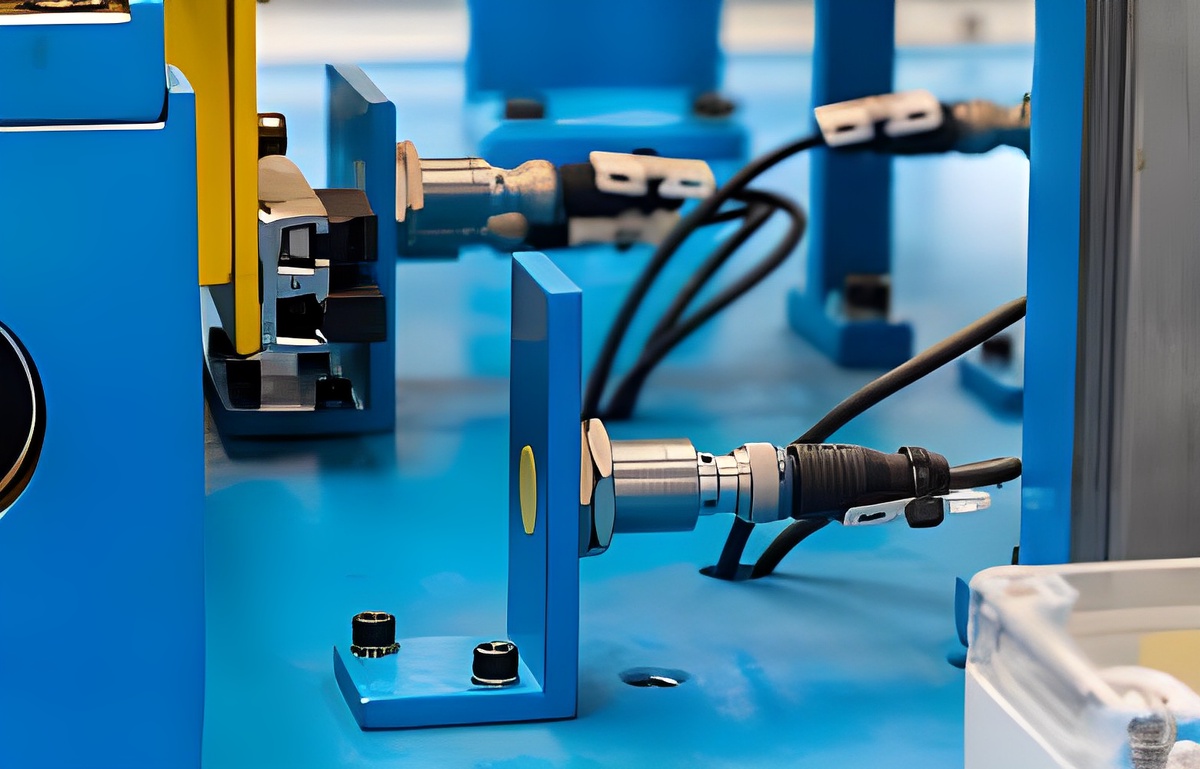

Capacitive sensors are the backbone of capacitive measurement systems. These sensors can detect changes in capacitance with high sensitivity, making them ideal for applications where precision is paramount. Typically, capacitive sensors consist of electrodes and a dielectric material. When subjected to changes in the surrounding environment, such as alterations in temperature or the presence of an object, the capacitance between the electrodes is affected.

Applications of Capacitive Measurement

-

Touchscreens and Human-Machine Interfaces (HMIs): Capacitive measurement is widely utilized in touchscreens, revolutionizing the way we interact with devices. The touch-sensitive capabilities of screens on smartphones, tablets, and other electronic devices are made possible through capacitive sensors. This has not only enhanced user experience but also allowed for more intuitive and responsive interfaces.

-

Proximity Sensing: In applications where detecting the proximity of an object is crucial, such as in automatic faucets or hand dryers, capacitive sensors play a vital role. Their ability to sense changes in capacitance without physical contact makes them suitable for proximity detection, contributing to improved hygiene and convenience.

-

Industrial Automation: Capacitive measurement finds extensive use in industrial automation for detecting the level of liquids or granular materials in containers. This application is particularly relevant in sectors such as food processing, pharmaceuticals, and chemicals, where precise level control is essential for efficient and safe operations.

-

Automotive Systems: The automotive industry leverages capacitive measurement for various purposes, including touch-sensitive controls, proximity sensors for parking assistance, and occupant detection for airbag deployment. The reliability and precision of capacitive sensors make them integral to enhancing both safety and user experience in vehicles.

-

Medical Devices: Capacitive measurement is employed in medical devices for applications such as fluid level monitoring, touch-sensitive controls in diagnostic equipment, and even non-invasive monitoring of physiological parameters. The non-contact nature of capacitive sensors is advantageous in medical settings, where hygiene and patient comfort are paramount.

Advantages of Capacitive Measurement

-

High Sensitivity: Capacitive sensors are known for their high sensitivity, enabling them to detect subtle changes in capacitance. This makes them suitable for applications where precision is crucial.

-

Non-Contact Operation: Unlike some other measurement techniques, capacitive measurement does not require physical contact between the sensor and the object being measured. This non-contact operation minimizes wear and tear, contributing to the longevity of the sensing system.

-

Versatility: Capacitive sensors can be adapted to measure a wide range of parameters, from position and displacement to humidity and pressure. This versatility makes them applicable in diverse industries and settings.

Challenges and Considerations

While capacitive measurement offers numerous advantages, it is essential to be mindful of certain challenges. Factors such as environmental conditions, material properties, and interference from nearby electrical sources can impact the accuracy of capacitive sensors. Calibration and proper system design are crucial to overcoming these challenges and ensuring reliable measurements.

Future Prospects and Innovations

As technology continues to evolve, so do the capabilities of capacitive measurement systems. Ongoing research aims to enhance sensor performance, reduce power consumption, and expand the range of measurable parameters. With advancements in materials science and signal processing, the future holds promising possibilities for capacitive measurement in fields ranging from healthcare to robotics.

Conclusion

In conclusion, capacitive measurement stands as a testament to the ingenuity of modern engineering, providing precise and reliable solutions to a multitude of measurement challenges. From the touchscreens we use daily to the intricate processes in industrial settings, capacitive sensors play a pivotal role in advancing technology and improving our quality of life. As we look toward the future, the continued refinement of capacitive measurement techniques promises even greater innovation and application across diverse industries.

No comments yet