The importance of quality control in the building industry cannot be ignored, especially when producing shuttering plywood. Shuttering plywood, which is frequently referred to as the foundation of concrete construction, is essential for offering structural support during the pouring and setting of concrete. Nevertheless, strict quality control procedures must be used all along the manufacturing process to guarantee peak performance and durability.

On building sites, shuttering plywood — also referred to as formwork plywood — is exposed to harsh elements such as dampness, pressure, and temperature changes. Therefore, any quality compromise may result in unsafe conditions, structural flaws, and higher maintenance expenses. Examining the different steps of production in further detail is necessary to comprehend the significance of quality control in shuttering plywood manufacture.

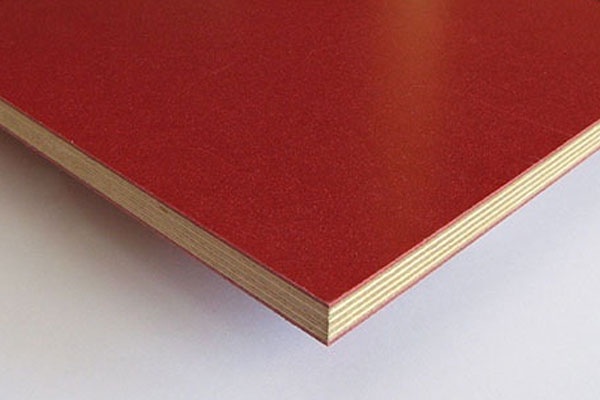

Ensuring quality control during the manufacturing of shuttering plywood starts from the first step, i.e. the selection of the right raw material. As we understand, shuttering plywood is made by sticking or adhering the layers of veneers together. Using good quality adhesives and ensuring proper pressing methods ensures the strength, longevity, and dimensional stability of the finished best shuttering plywood. Manufacturers like Bhutan Tuff carefully check and source premium wood veneers and adhesives that adhere to industry requirements.

Thereafter the processing of quality raw materials through several stages, including cutting, drying, glueing, and pressing, quality control measures are set up at every stage to identify any deviations from the predetermined parameters. For example, to avoid the plywood sheets warping or delamination during the drying process, the moisture content needs to be closely watched. In the same way, uniform and consistent adhesive application is necessary to ensure the ideal bonding strength.

Adhering to industrial certifications and regulations is an important aspect of quality control in the shuttering plywood manufacturing process. It is essential to follow all the necessary rules to ensure that product quality and safety are established by regulatory organizations like the International Organization for Standardisation (ISO). Manufacturers like Bhutan Tuff are keen to ensure that they are committed to providing plywood that meets or above industry standards by obtaining the necessary certifications.

Moreover, testing and assessment processes are an important aspect of quality control, which goes beyond the manufacturing floor. Samples of plywood have to pass the testing procedures to check out its mechanical qualities, including shear, flexibility, and tensile strength. The accelerated ageing test is another important procedure used to assess resilience to environmental conditions such as dampness, fungal degradation, and insect infestation.

Investing in quality control methods ensures the fabrication of an industry-standard product and leads to customer satisfaction and brand reputation in addition to protecting the integrity of the finished product. Shuttering plywood is a crucial material that builders would meet the demands of construction projects confidently. Manufacturers build long-lasting relationships with their customers by adhering strictly to quality standards. Effective quality control procedures also minimise waste and save costs eventually resulting in increased production and profitability.

To conclude, it is critical to recognise the significance of quality control in shuttering plywood production to produce high-quality goods that satisfy the requirements of distinct building projects. If you have any further queries you must ask the experts at Bhutan Tuff or explore the website to know in depth. The company is a leading producer of various kinds of plywood like flexible plywood, commercial plywood, and many more. Visit the website now!

No comments yet