In today's consumer driven market product durability and safety cannot be ignored for manufacturers across industry. Whether it is electronics automotive parts or household appliances, ensuring that the products can withstand the rigors of everyday use and unexpected accidents is very important. You must know that drop test machine, plays a very important role in the process. By subjecting products to controlled impact testing stimulating real-world scenarios and evaluating their performance under stress you cannot ignore the role of drop tester. In this guide you can learn everything about the functionality applications and significance of drop test machines and ensuring product durability and safety.

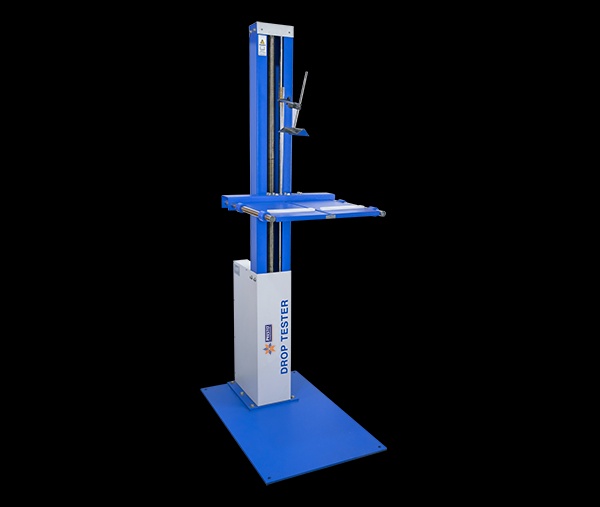

What is a drop test machine?

You need to know that drop test machine, is also known as a drop tester or an impact tester. It is a specialized testing instrument used to understand the impact resistance and durability of the products when subjected to products or impacts. The machine stimulate different drop scenarios like falls from specific heights or collision with surfaces to evaluate how the products will withstand the mechanical shocks. You need to know that the drop test machines come in different configurations like hydraulic and electromechanical systems catering to unique testing requirements of different industries.

Components of drop tester

- The drop platform is the surface on which the test specimen or the product is placed before it is subjected to the drops. It is basically equipped with fixture clamps or adapters to securely hold the product in place during testing.

- The guided form mechanism controls the element of the drop platform and ensure that it follows A predefined trajectory or path during testing. It might include rails guides or pneumatic cylinders which regulate the speed and direction of the drop.

- Drop test machines allow users to adjust the height from which the product is dropped to simulate different impact scenarios. This features allows testing at different drop heights angles and orientations to understand the product performance under different conditions.

- An impact detection system is integrated in the drop test machine to measure and record the impact force acceleration and other relevant parameters during testing. The data provides you valuable insights in the products response to mechanical shocks and helps you evaluate the structural integrity and resilience

- Well, you need to know that the control panel and software interface allows you to configure test parameters set drop conditions and monitor the test progress in real time. They can facilitate data analysis reporting and documentation of test results for quality assurance and compliance purpose.

Applications of drop test machine

- In the electronics industry drop tests are basically used to understand impact resistance of smartphones tablets and laptops and other electronic devices. They can help you identify the weak points in product design and packaging and optimize them to withstand accidental drops and impact.

- In the automotive and aerospace industries the drop tester is basically used to test the durability of the packaging materials and shipping crates. They stimulate the impact and vibrations encountered during transportation and storage to ensure that your products remain intact and undamaged throughout the supply chain.

- In the medical wise and pharmaceutical industries, drop test machines are used to understand the impact resistance of the medical equipment. They help you ensure the safety and reliability of healthcare products and reduce the risk of damage or contamination during handling and use.

Importance of drop test machines

- Drop test machines play a very important role in quality assurance by identifying design flaws and manufacturing defects and material weakness that could compromise product performance and safety. By subjecting products to controlled impact testing and manufacturers can detect potential issues early in the development process and implement corrective measures to improve the product quality and reliability.

- Many industries have regulatory standards and certification requirements governing Product Safety and durability. You need to know that the drop test machines allow you to conduct compliance testing and demonstrate that your products meet or exceed the industry specific regulations and standards. When you compile with these standards it can improve customer confidence, reduce liability risks and facilitate market access for the products and services.

So, you need to know that the drop test machines are very important tools for evaluating the impact, resistance and durability of your products across industries.

No comments yet