We all know what high feed milling is, but various other factors are to be known. So today, in this article, we will discuss a few ways to optimize high-feed milling. We all know that high-feed milling tries to remove maximum material in the shortest time, which is considered one of the best processes for many business organizations. The report says that it has also been seen that many organizations don't prefer using this technique as it can cause unfavorable results if not applied properly. So, if you're planning to apply this technique, make sure you apply it correctly. Expert says that the process offers excellent productivity. As per the latest research, many other things must be considered to make this process work.

Machine Tools

Highly advanced machine tools are essential as the cutter runs at high feed, which needs control and the machine to stay updated with all the demands. The report says advanced equipment is more beneficial when dealing with milling technology. You can run high-feed mills on old machines, but it won't work at an incredible speed.

Insert Grade

When you plan to work with this process, ensure you have the best insert grade, as no one wants their tool to fail prematurely, especially when you are under a light-out operation. Choosing the correct insert grade for the process will help you increase tool predictability, less reworking, and fewer rejects. Along with all these tools, there are some more tools that are needed to be considered, and they are:

- Engaged tools

- Programming

- Machining application

- Inserts

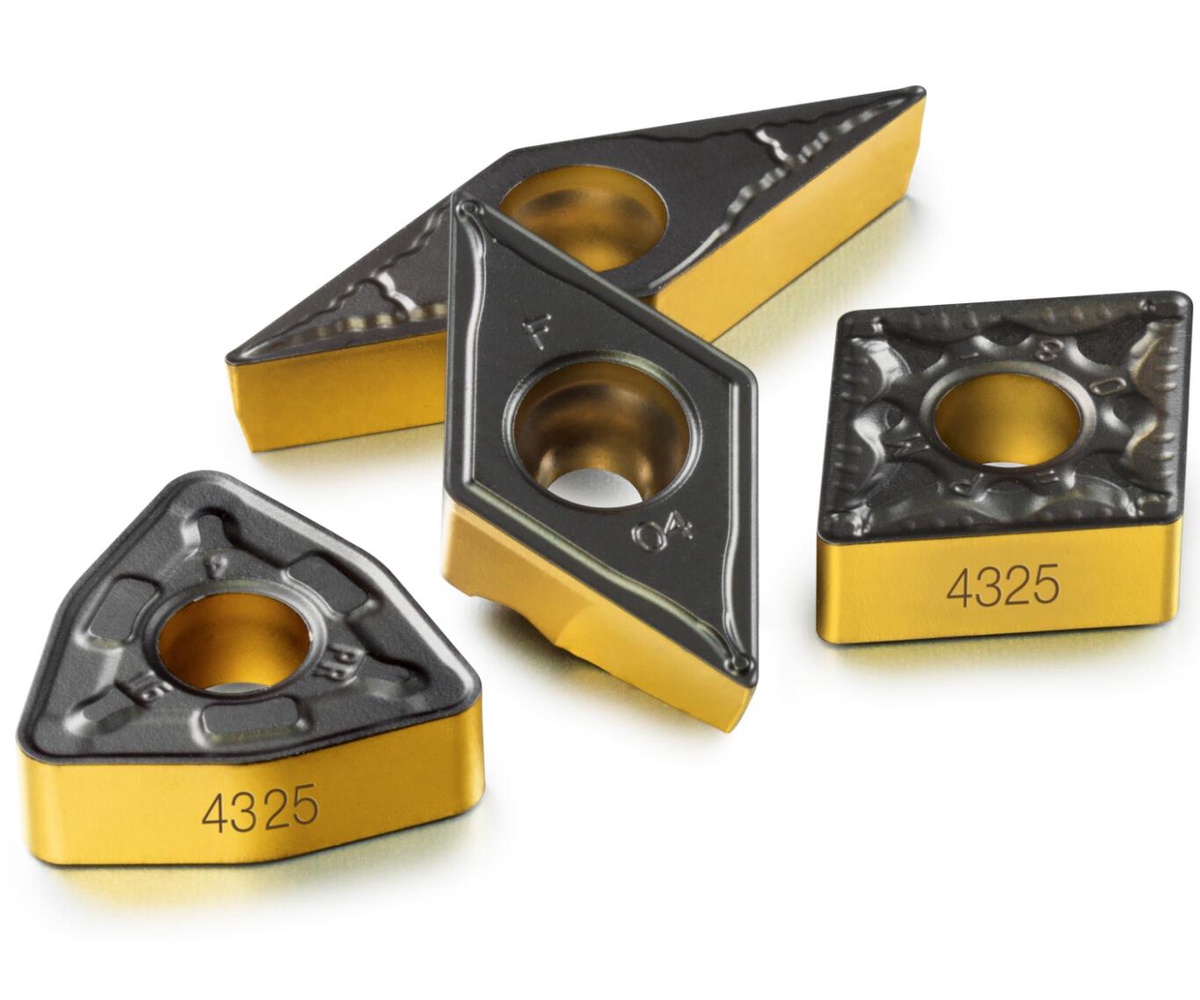

All You Need To Know About ISO Turning Inserts

Inserts are simply small things we generally use to cut material, but unfortunately, these small things hugely impact our shop's profitability. Because of its excellent properties, everyone should gather knowledge about ISO turning inserts. Inserts are known by their ISO naming convention, which speaks about their size and shape, and every number and alphabet signifies a part of the insert's size and shape.

Action Point

If you decide on the tooling part (e.g., imagine you are the process planner, programmer, or industrial engineer), you need to know all the naming conventions nicely and the reason behind choosing the size and shape of an insert. Considering basic knowledge about the ISO turning, insert terminology if you want to gather information.

Conclusion

Suppose you are one who is gathering knowledge about ISO turning insert and high feed milling. In that case, this article is perfect for you as it contains all the necessary relevant information for the following. You can also stick to the browser to learn more about them.

No comments yet