Introduction

Welcome to this comprehensive guide on properly storing and handling welding electrodes. If you're involved in welding operations, you understand welding electrodes' critical role in achieving strong and durable welds. However, even the highest-quality electrodes can lose effectiveness if not stored and handled correctly. This article will delve into essential tips and best practices to ensure your welding electrodes remain in optimal condition, allowing you to deliver top-notch welding results consistently. If you want to get a quote on welding electrode you can contact Goodluck Metal Corporation. They are the leading supplier of welding electrodes, speciallly e308l electrode.

Why Proper Storage and Handling Matter?

Before we delve into the specifics, let's highlight the significance of properly storing and handling welding electrodes. These small but crucial consumables are responsible for conducting electricity to create the arc necessary for welding. If they are mishandled or improperly stored, it can lead to several problems, including:

- Moisture Absorption: Welding electrodes are susceptible to moisture absorption, which can lead to porosity and cracks in welds, affecting their integrity.

- Contamination: Exposure to dust, dirt, or other contaminants can compromise the quality of the electrode and the resulting weld.

- Electrode Brittleness: Improper handling, such as dropping or mishandling electrodes, can lead to brittleness, making them more prone to breakage during use.

- Reduced Performance: Poorly stored electrodes can suffer from reduced arc stability and inconsistent weld penetration, leading to subpar welds.

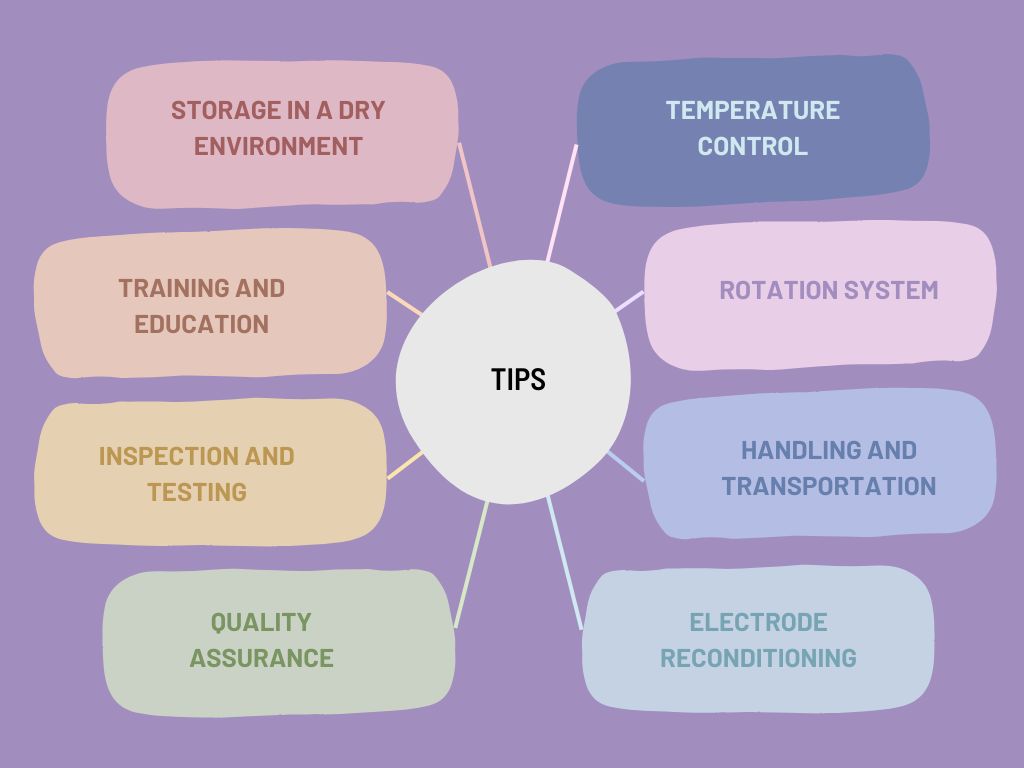

Now, let's dive into the essential tips for proper storage and handling to maximize the performance and longevity of your welding electrodes.

Tip 1: Storage in a Dry Environment

The first and most critical aspect of electrode care is storage in a dry environment. Moisture is the number one enemy of welding electrodes, as it can cause hydrogen embrittlement, leading to weld defects. To prevent moisture absorption, follow these steps:

- Store electrodes in airtight containers or resealable bags.

- Add desiccant packs to the storage containers to absorb any residual moisture.

- Avoid storing electrodes directly on the floor; use pallets or shelves to keep them off the ground.

Tip 2: Temperature Control

Temperature fluctuations can also impact the quality of welding electrodes. Extremes of heat or cold can affect the coating and the electrode's core. Here's how to maintain proper temperature control:

- Store electrodes in a climate-controlled environment with consistent temperature and humidity levels.

- Avoid exposure to direct sunlight or other heat sources.

Tip 3: Rotation System

Implementing a rotation system is an effective strategy for businesses that use welding electrodes frequently. This ensures that older electrodes are used first, reducing the risk of expired or deteriorated ones in storage.

Tip 4: Handling and Transportation

Proper handling and transportation are crucial to maintaining the integrity of welding electrodes. Follow these guidelines:

- Always handle electrodes with clean, dry gloves to prevent contamination.

- Avoid dropping or mishandling electrodes to prevent brittleness.

- During transportation, secure the electrodes to prevent movement and potential damage.

Tip 5: Electrode Reconditioning

If you suspect your welding electrodes may have absorbed moisture or become contaminated, consider reconditioning them before use. This process involves baking the electrodes to remove moisture and restore their performance. However, be cautious and follow the manufacturer's recommendations, as over-baking can harm the electrodes.

Tip 6: Quality Assurance

Investing in high-quality welding electrodes is crucial for obtaining consistent and reliable welds. Choose reputable brands and suppliers to ensure the best results. Low-quality electrodes may be more prone to moisture absorption and can lead to welding defects.

Tip 7: Inspection & Testing

Regularly inspect your welding electrodes for any signs of damage, such as cracks, chipping, or discolouration. Perform test welds to ensure the electrodes are performing as expected. If you notice any abnormalities, replace the electrodes immediately.

Tip 8: Training and Education

Proper storage and handling of welding electrodes should be part of your welders' training program. Educate your team on best practices and the importance of electrode care to avoid common pitfalls.

Conclusion

By following these tips for properly storing and handling welding electrodes, you can ensure that your welding operations are consistently efficient and produce high-quality welds. Remember, welding electrodes are not just consumables but the backbone of every successful welding project. So, prioritize their care and maintenance to stay ahead in the competitive world of welding and fabrication.

No comments yet