Fuel injectors play a crucial role in the operation of diesel engines, ensuring precise fuel delivery and combustion. As the heart of the fuel delivery system, these small yet vital components determine the engine's efficiency, power output, and emissions. To achieve optimal performance and reliability, diesel engine enthusiasts and mechanics turn to aftermarket upgrades like the Fuel Injector Return Banjo Bolt Kit and Injector Cups.

The Fuel Injector Return Banjo Bolt Kit serves as a critical component that enhances the fuel injection process by securing the return fuel line to the fuel injector. By providing a secure and leak-free connection, this kit ensures that the injector operates at its peak efficiency, maximizing fuel delivery and minimizing fuel waste.

In the following blog, we will delve deeper into the benefits and significance of these upgrades, exploring their compatibility with different diesel engine models and providing valuable insights on their installation and maintenance. Join us as we uncover the power of Fuel Injector Return Banjo Bolt Kit and Injector Cups, elevating your diesel engine's performance to new heights.

Understanding Fuel Injectors: Role and Importance

Fuel injectors are integral components of the diesel engine's fuel delivery system, responsible for precisely delivering the right amount of fuel into the combustion chamber at the correct time. Unlike carburetors, which were commonly used in older engines, fuel injectors cups provide a more efficient and controlled method of fuel delivery, offering several benefits for engine performance and efficiency.

Role of Fuel Injectors in the Diesel Engine's Fuel Delivery System:

Precise Fuel Delivery: Fuel injectors spray fuel in a fine mist directly into the combustion chamber under high pressure. This precision ensures an accurate fuel-air mixture, essential for efficient combustion.

Optimized Fuel Atomization: The high-pressure spray pattern allows for better fuel atomization, breaking down the fuel into tiny droplets. This improves the surface area of fuel exposed to oxygen, promoting more complete combustion.

Injection Timing Control: Modern fuel injection systems use electronic controls to precisely time the injection process. This allows the engine management system to adjust the timing based on various factors such as engine load, RPM, and temperature, optimizing performance under different driving conditions.

Improved Combustion Efficiency: Efficient combustion reduces fuel wastage, emissions, and the production of harmful pollutants. Properly atomized fuel ensures that the engine extracts the maximum energy from the fuel, translating into better fuel efficiency.

Importance of Proper Fuel Injection for Engine Efficiency and Power:

Power Output: Correct fuel injection directly influences the engine's power output. A well-timed and precisely metered fuel delivery allows for optimal combustion, generating more power per unit of fuel consumed.

Fuel Efficiency: Proper fuel injection leads to improved fuel efficiency, meaning the engine can produce more work from less fuel. This results in fewer trips to the gas station and reduced operating costs for vehicle owners.

Emissions Reduction: Efficient combustion reduces the formation of harmful pollutants in the exhaust gases, contributing to lower emissions and compliance with environmental regulations.

Engine Smoothness and Reliability: Properly functioning fuel injectors ensure smoother engine operation, reducing vibrations and enhancing overall driving comfort. Additionally, precise fuel delivery helps prevent engine damage caused by incomplete combustion.

Fuel Injector Return Banjo Bolt Kit

The Fuel Injector Return Banjo Bolt Kit serves a crucial role in the diesel engine's fuel injection system. Its primary purpose is to secure the return fuel line to the fuel injector, ensuring a reliable and leak-free connection. The Banjo Bolt Kit typically consists of banjo bolts, washers, and seals necessary for proper installation.

Purpose and Function of Fuel Injector Return Banjo Bolt Kit

Secure Connection: The Banjo Bolt Kit securely fastens the return fuel line to the fuel injector, preventing any potential fuel leaks or seepage that could lead to inefficient fuel delivery or engine performance issues.

Optimized Fuel Flow: By creating a secure connection, the Banjo Bolt Kit ensures consistent and uninterrupted fuel flow back to the fuel tank. This contributes to efficient fuel circulation within the fuel injection system, maintaining a stable fuel pressure.

Benefits of Fuel Injector Return Banjo Bolt Kit

- Prevents Fuel Leaks: The Banjo Bolt Kit's design with proper seals and washers ensures a tight connection between the return fuel line and the fuel injector. This prevents fuel leaks and wastage, promoting more efficient fuel utilization.

- Improved Fuel Efficiency: By eliminating potential fuel leaks, the Banjo Bolt Kit helps maintain the proper fuel pressure and fuel flow rates required for efficient combustion. This, in turn, leads to improved fuel efficiency and reduced fuel consumption.

- Enhanced Engine Performance: A secure and consistent fuel supply enhances engine performance by ensuring a steady and precise fuel delivery. This contributes to smoother engine operation and better power output.

- Reliability and Durability: The Banjo Bolt Kit's high-quality construction and secure fastening minimize the risk of fuel system malfunctions and potential damage, contributing to the long-term reliability and durability of the engine.

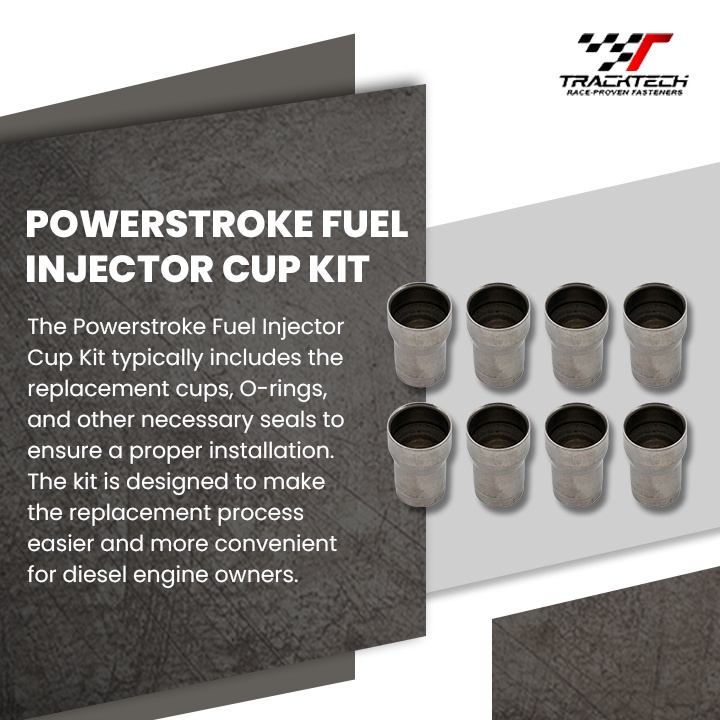

Injector Cups

Injector Cups are essential components used during fuel injector installations in diesel engines. Also known as injector sleeves or injector seat cups, they play a crucial role in creating a reliable seal between the fuel injector and the cylinder head.

Significance of Injector Cups in Fuel Injector Installations:

Seal and Leak Prevention: Injector Cups provide a tight and secure seal between the fuel injector and the cylinder head. This prevents fuel from leaking into the combustion chamber or escaping into the cylinder head, ensuring efficient fuel delivery.

Heat Dissipation: Injector Cups help dissipate the intense heat generated during the combustion process. They act as a barrier between the hot combustion gases and the fuel injector, preventing potential heat-related issues and maintaining injector performance.

Role of Injector Cups in Preventing Leaks

- Secure Injector Fitment: The precise design of injector cups allows for a perfect fit between the injector and the cylinder head, reducing the risk of misalignment and fuel leaks.

- Fuel System Integrity: Properly installed injector cups create a hermetic seal, maintaining the fuel system's integrity and preventing fuel seepage that could lead to performance issues.

Compatibility and Application

The Fuel Injector Return Banjo Bolt Kit and Injector Cups are designed to be compatible with a wide range of diesel engine models, making them versatile upgrades for various diesel vehicles and industrial machinery. These components are often engineered to meet OEM specifications, ensuring a perfect fit and seamless integration into the fuel injection system of different diesel engines.

Their application extends to popular diesel vehicle brands such as Ford, Chevrolet, Dodge, GMC, and others, including light-duty trucks, heavy-duty trucks, and commercial vehicles. Moreover, they find use in industrial equipment like generators, construction machinery, and agricultural machinery, where reliable and efficient fuel delivery is essential for optimal performance.

Performance Enhancement

The presence of a well-maintained Fuel Injector Return Banjo Bolt Kit and properly installed Injector Cups significantly enhances the fuel injection performance, positively impacting various aspects of engine operation.

- Fuel Efficiency: The secure connection provided by the Banjo Bolt Kit ensures consistent fuel flow and proper fuel pressure, leading to better fuel atomization and combustion efficiency. This results in improved fuel economy and reduced fuel consumption.

- Power Output: With optimized fuel delivery, the engine experiences enhanced combustion, allowing it to extract more energy from the fuel. As a result, the power output of the engine increases, leading to improved acceleration and towing capabilities.

- Emission Reduction: Efficient fuel injection results in cleaner and more complete combustion, minimizing the production of harmful emissions. This translates to reduced nitrogen oxides (NOx), particulate matter, and hydrocarbons, promoting a greener and more environmentally friendly operation.

Installation and Maintenance

Installing the Fuel Injector Return Banjo Bolt Kit

- Begin by safely relieving the fuel system pressure to prevent fuel spray during installation.

- Carefully remove the old banjo bolts, washers, and seals from the return fuel line and fuel injectors.

- Clean the banjo bolt and injector surfaces thoroughly to ensure a clean mating surface.

- Install the new banjo bolts, ensuring they are correctly aligned and torqued to the manufacturer's specifications.

- Replace the washers and seals, making sure they are properly seated to prevent any fuel leaks.

- Reconnect the fuel lines and check for any signs of leaks.

Installing the Injector Cups

- Remove the old injector cups, taking care not to damage the cylinder head or injector bores.

- Clean the injector bore thoroughly to remove any debris or carbon buildup.

- Lubricate the new injector cups with a light oil or assembly lubricant before installing them into the injector bores.

- Gently tap the new injector cups into place, ensuring they are fully seated and flush with the cylinder head surface.

- Reinstall the injectors, making sure they fit snugly into the new injector cups.

- Perform a fuel system pressure test to check for leaks and verify the proper installation of the injector cups.

Maintenance Tips

- Regularly inspect the Banjo Bolt Kit and Injector Cups for signs of wear, damage, or fuel leaks.

- Keep the fuel system clean and free from debris to ensure proper fuel flow and injector performance.

- Follow the manufacturer's recommended maintenance intervals for the fuel injection system and its components.

- Use high-quality fuel and fuel additives to promote cleaner combustion and reduce the risk of injector clogging.

Conclusion

In conclusion, the Fuel Injector Return Banjo Bolt Kit and Injector Cups are essential upgrades that significantly improve fuel injection performance in diesel engines. Their compatibility with various engine models and applications ensures versatile use. These upgrades enhance fuel efficiency, power output, and emission reduction, promoting a greener and more efficient engine operation. Proper installation and maintenance are key to maximizing their benefits, providing a reliable and powerful fuel delivery system for your diesel engine. Trust in these components to elevate your engine's performance and make every journey more efficient and powerful.

No comments yet