In the ever-advancing landscape of power generation and industrial processes, the role of steam turbine and gas turbine components has significantly evolved. These critical components have come a long way from their humble beginnings, ushering in a new era of efficiency, reliability, and sustainability.

Steam Turbine Components: Powering the Past and Present

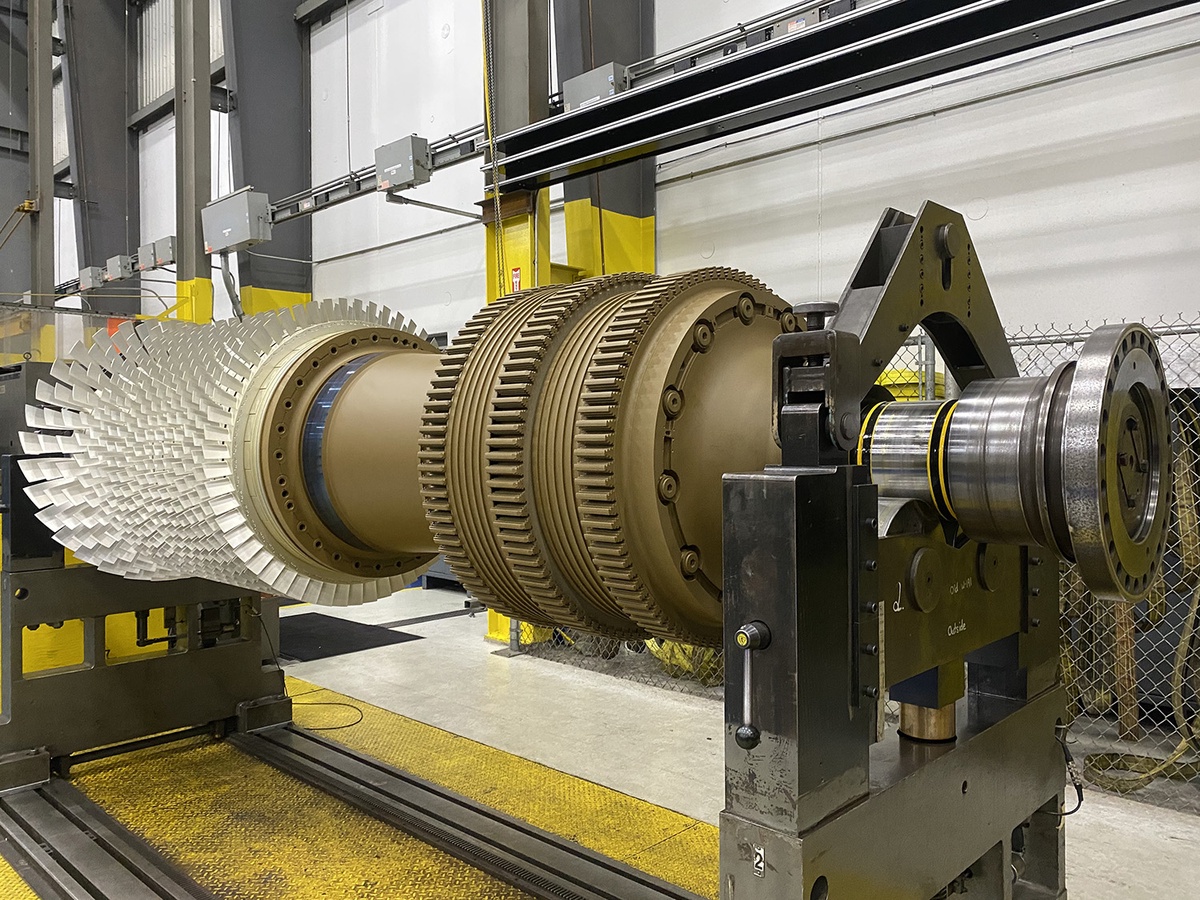

Steam turbines have been a fundamental part of power generation for over a century. Their components, which include rotors, blades, nozzles, and casings, have witnessed remarkable changes. Modern steam turbine components are precision-engineered to maximize energy conversion and reduce waste.

The evolution of steam turbine components has led to enhanced thermal efficiency, enabling power plants to generate electricity with lower fuel consumption and reduced greenhouse gas emissions. Advancements in materials, manufacturing techniques, and design have contributed to their increased reliability and longevity.

Gas Turbine Components: A Leap Forward in Efficiency

Gas turbines have gained prominence for their versatility in various industries, including aviation and power generation. The components of gas turbines, such as compressor blades, combustion chambers, and turbine blades, have undergone significant improvements to meet the increasing demands for efficiency and environmental sustainability.

These components have been redesigned to withstand higher temperatures and pressures, leading to enhanced power output and reduced emissions. Additionally, innovations in cooling technologies have prolonged the lifespan of gas turbine components, making them more cost-effective in the long run.

The Convergence of Steam and Gas Turbine Components

In modern industry, it's not uncommon to find combined cycle power plants that utilize both steam and gas turbines to maximize energy production. This integration has led to the development of sophisticated components designed to work seamlessly together. Steam turbine and gas turbine components are now engineered with compatibility in mind, resulting in greater overall system efficiency.

The Role of Digitalization and Monitoring

The digital revolution has also played a crucial role in the evolution of turbine components. Monitoring systems, predictive maintenance, and real-time data analytics have become essential tools in ensuring the optimal performance and reliability of these components. With these technologies, manufacturers and operators can proactively address issues and prevent costly downtime.

Looking Ahead: The Future of Turbine Components

As the demand for cleaner and more efficient energy sources continues to grow, the evolution of steam turbine and gas turbine components is expected to continue. Innovations in materials, 3D printing, and advanced coatings are likely to further improve their performance and durability.

In conclusion, the evolution of steam turbine and gas turbine components has been instrumental in shaping the landscape of modern industry. These components have advanced significantly in terms of efficiency, reliability, and sustainability, and their continued development will play a crucial role in meeting the world's energy needs while minimizing environmental impact. As technology continues to advance, the future of turbine components holds promise for even greater achievements in power generation and industrial processes.

No comments yet