Butterfly valves are crucial components in various industries, offering efficient flow control solutions. Whether it's in water treatment plants, oil refineries, or food processing facilities, selecting the right butterfly valve supplier is paramount. This comprehensive guide will walk you through everything you need to know about finding the best butterfly valves supplier for your needs.

Introduction to Butterfly Valves

Butterfly valves are quarter-turn rotational motion valves, typically used to regulate fluid flow. They consist of a circular disc or vane with its pivot axis at right angles to the flow direction within a pipe. These valves are widely favored for their simplicity, lightweight, and quick operation.

Types of Butterfly Valves

Concentric Butterfly Valves

Concentric butterfly valves have a resilient rubber seat with a centered disc. They are commonly used in low-pressure applications.

Eccentric Butterfly Valves

Eccentric butterfly valves have the shaft offset from the centerline of the disc and seat. This design reduces wear and tear, making them suitable for high-pressure applications.

Double Offset Butterfly Valves

Double offset butterfly valves feature both the shaft and the center of the disc offset from the centerline of the bore. They offer improved sealing performance and are ideal for high-performance applications.

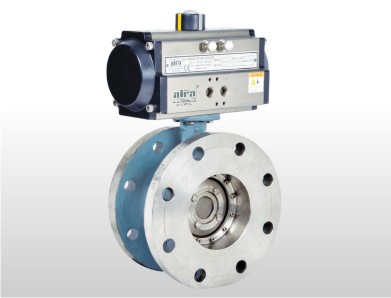

Triple Offset Butterfly Valves

Triple offset butterfly valves have the shaft and the center of the disc offset from the centerline of the bore in three directions. This design provides bubble-tight shut-off and is commonly used in critical applications such as in the oil and gas industry.

Components of Butterfly Valves

Butterfly valves consist of several key components, including the body, disk, seat, and actuator. The body is the outer shell of the valve, housing the internal components. The disk, also known as the butterfly, controls the flow by rotating within the valve body. The seat provides a sealing surface for the disk, preventing leakage. The actuator is responsible for operating the valve, either manually or automatically.

Applications of Butterfly Valves

Butterfly valves find applications in various industries, including HVAC systems, water treatment plants, chemical processing, and power generation. Their versatility, reliability, and cost-effectiveness make them a popular choice for flow control.

Factors to Consider When Choosing a Butterfly Valve Supplier

Selecting the right butterfly valve supplier requires careful consideration of several factors to ensure optimal performance and reliability.

Quality of Products

Choose a supplier that offers high-quality products manufactured using durable materials and precise engineering processes.

Experience and Reputation

Look for a supplier with a proven track record and positive reputation in the industry, with years of experience delivering reliable solutions.

Customization Options

Opt for a supplier that offers customization options to tailor their products to your specific requirements and applications.

Technical Support

Ensure the supplier provides comprehensive technical support, including installation guidance, troubleshooting assistance, and maintenance advice.

Cost-effectiveness

Consider the overall value proposition offered by the supplier, including the initial cost, long-term maintenance expenses, and return on investment.

Top Features to Look for in a Butterfly Valve Supplier

When evaluating butterfly valve suppliers, keep an eye out for the following key features:

Product Range

Choose a supplier that offers a diverse range of butterfly valves to meet your various application needs.

Quality Assurance

Select a supplier that prioritizes quality assurance measures, including rigorous testing and certification processes.

Certifications and Compliance

Ensure the supplier's products comply with relevant industry standards and regulations, such as ISO certification and API standards.

Delivery Time and Logistics

Consider the supplier's delivery capabilities and logistics network to ensure timely and efficient delivery of products.

How to Evaluate Butterfly Valve Suppliers

Evaluating butterfly valve suppliers requires thorough research and assessment to make an informed decision.

Research and Reviews

Conduct online research and read customer reviews to gather insights into the supplier's reputation and customer satisfaction levels.

Requesting Quotations

Request quotations from multiple suppliers and compare pricing, product specifications, and additional services offered.

Site Visits and Inspections

Arrange site visits or inspections to assess the supplier's facilities, manufacturing processes, and product quality firsthand.

Benefits of Choosing the Right Butterfly Valve Supplier

Selecting the right butterfly valve supplier offers several benefits, including:

- Enhanced performance and reliability of your fluid control systems.

- Reduced maintenance costs and downtime.

- Access to expert technical support and guidance.

- Long-term partnership opportunities for future projects.

Case Studies: Successful Implementations

Explore case studies of successful implementations showcasing how choosing the right butterfly valve supplier has resulted in improved efficiency and performance for various industries.

Common Mistakes to Avoid When Selecting a Butterfly Valve Supplier

Avoid these common pitfalls when selecting a butterfly valve supplier:

- Focusing solely on price and overlooking quality and reliability.

- Neglecting to assess the supplier's reputation and track record.

- Overlooking the importance of technical support and after-sales service.

- Ignoring compliance requirements and certifications.

Tips for Maintaining Butterfly Valves

Proper maintenance is essential to ensure the longevity and optimal performance of butterfly valves. Follow these tips for effective valve maintenance:

- Regularly inspect valves for signs of wear, corrosion, or leakage.

- Ensure smooth operation by lubricating moving parts.

- Schedule routine maintenance tasks, including cleaning and calibration.

- Ensure that personnel are trained on how to operate and maintain valves properly.

Conclusion

Choosing the right butterfly valve supplier is crucial for the success and efficiency of your fluid control systems. By considering factors such as product quality, experience, and technical support, you can find a reliable supplier that meets your specific needs and requirements.

No comments yet