In the realm of modern materials, High-Density Polyethylene (HDPE) sheets have established themselves as a versatile and indispensable component. Behind these sheets lies a meticulous process of manufacturing that blends precision, innovation, and a commitment to quality. In this exploration, we delve into the intricacies of HDPE sheets manufacturing, uncovering the journey from raw materials to the final product.

Raw Materials: Building Blocks of Quality

High-Quality Resins: The Foundation of HDPE

The manufacturing journey begins with the selection of high-quality HDPE resins. These resins, derived from ethylene monomers through a polymerization process, serve as the foundational building blocks of HDPE sheets. The choice of resins influences the material's strength, flexibility, and resistance to environmental factors, setting the stage for the production of top-tier HDPE sheets.

Additives for Enhancement: Tailoring Properties

Manufacturers often introduce additives to the HDPE resin to enhance specific properties. UV stabilizers may be incorporated to ensure resistance to sunlight, while fire-retardant additives enhance safety. The careful balance of additives allows manufacturers to tailor HDPE sheets to meet diverse industry requirements, from construction to healthcare and beyond.

Manufacturing Process: Precision in Action

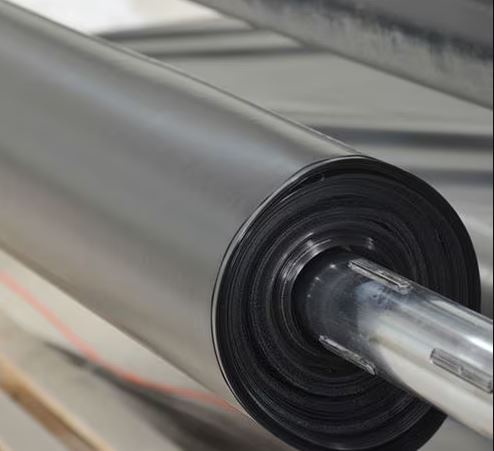

Extrusion: Shaping the Foundation

The heart of HDPE sheets manufacturing lies in the extrusion process. HDPE resin, blended with additives, is melted and then extruded through a die to create a continuous, flat sheet. This process ensures uniformity in thickness and density, laying the foundation for sheets with consistent mechanical properties. Extrusion not only guarantees precision but also enables the production of sheets in varying sizes and thicknesses.

Cooling and Cutting: Solidifying Form

Once extruded, the hot HDPE sheet undergoes a rapid cooling process to solidify its form. This cooling stage is crucial for maintaining the sheet's structural integrity and preventing warping or deformities. Following cooling, the sheet is precisely cut to the desired dimensions, showcasing the precision that defines the manufacturing process.

Quality Control: The Guardian of Excellence

Thickness Uniformity Checks: Precision Assurance

Quality control measures are integral to HDPE sheets manufacturing. Advanced technology is employed to ensure the thickness of each sheet meets exact specifications. This meticulous monitoring guarantees uniformity, whether the sheets are destined for construction projects, healthcare applications, or intricate industrial uses.

Comprehensive Testing: Beyond the Surface

Beyond thickness checks, comprehensive testing is conducted to assess various mechanical and chemical properties. Tensile strength, impact resistance, and chemical stability undergo scrutiny to ensure that each HDPE sheet meets or exceeds industry standards. This commitment to quality testing underscores the manufacturer's dedication to delivering sheets of unparalleled performance.

Customization: Meeting Diverse Industry Needs

Color Variations: Aesthetic Versatility

HDPE sheets manufacturers recognize the importance of aesthetic versatility. Through the addition of pigments or colorants during the manufacturing process, a spectrum of color variations is achieved. This customization option caters to industries where visual appeal is as crucial as functional performance, ranging from architectural applications to consumer products.

Specialty Additives: Tailoring Functionality

In certain applications, specialty additives are introduced during manufacturing to imbue HDPE sheets with specific functionalities. Whether it's antimicrobial properties for healthcare settings or conductive additives for electronic applications, manufacturers have the expertise to tailor HDPE sheets to address the unique demands of diverse industries.

Sustainability: Crafting with Responsibility

Recycling Initiatives: Closing the Loop

Sustainability takes center stage in HDPE sheets manufacturing. Manufacturers actively engage in recycling initiatives, ensuring that production waste and post-consumer HDPE sheets are efficiently recycled. This commitment to a circular economy aligns with global sustainability goals, reducing the environmental impact associated with plastic production.

Efficient Energy Use: Minimizing Footprint

Manufacturers implement energy-efficient practices during the manufacturing process, from the melting of resins to the extrusion and cooling stages. This not only minimizes the environmental footprint but also reflects a responsible approach to resource utilization. Efficient energy use is integral to the holistic sustainability ethos of HDPE sheets manufacturing.

Nanotechnology Integration: Enhancing Performance at the Molecular Level

Nano-Enhanced HDPE: A Technological Leap

The integration of nanotechnology into HDPE sheets manufacturing marks a technological leap. By incorporating nanomaterials, manufacturers enhance the material's mechanical properties at the molecular level. Nano-enhanced HDPE exhibits improved strength, durability, and even advanced functionalities such as self-cleaning surfaces or enhanced electrical conductivity. This infusion of nanotechnology pushes the boundaries of what HDPE sheets can achieve in various industries.

Smart HDPE Sheets: Embracing the Internet of Things (IoT)

IoT-Enabled Sensors: Intelligence in Every Sheet

The evolution of HDPE sheets extends to the realm of smart materials. IoT-enabled sensors embedded within HDPE sheets create a new paradigm of functionality. These sensors can monitor structural integrity, environmental conditions, or even provide real-time data on the sheet's performance. Smart HDPE sheets find applications in structural health monitoring, ensuring early detection of potential issues and contributing to predictive maintenance strategies.

3D Printing Advancements: Tailoring HDPE Sheets with Precision

Additive Manufacturing: Design Freedom Unleashed

Advancements in 3D printing technology open new avenues for tailoring HDPE sheets with precision. Additive manufacturing allows for the creation of complex geometries, intricate patterns, and customized features within HDPE sheets. This level of design freedom not only expands the aesthetic possibilities of HDPE but also enables the production of sheets with specific structural enhancements based on the intended application.

Biodegradable HDPE: Pioneering Sustainable Solutions

Eco-Friendly Additives: Redefining End-of-Life Scenarios

In response to the global push for sustainable materials, manufacturers are exploring the integration of biodegradable additives into HDPE sheets. These additives facilitate the breakdown of HDPE sheets over time, addressing concerns related to plastic waste. Biodegradable HDPE sheets represent a pioneering step towards creating environmentally friendly alternatives while retaining the material's inherent strengths.

Interactive Surface Technologies: Transforming User Experiences

Touch-Sensitive HDPE: A Fusion of Functionality

The integration of touch-sensitive technologies into HDPE sheets transforms them into interactive surfaces. This innovation finds applications in retail displays, educational settings, and interactive architectural elements. Touch-sensitive HDPE opens up new possibilities for user engagement, creating immersive experiences and pushing the boundaries of how HDPE sheets can interact with the surrounding environment.

Collaborative Research Initiatives: Shaping Tomorrow's Innovations

As HDPE sheets continue to evolve, collaborative research initiatives play a pivotal role in shaping tomorrow's innovations. Manufacturers, researchers, and industry experts collaborate to explore novel materials, advanced manufacturing techniques, and cutting-edge applications. These initiatives propel HDPE sheets into uncharted territories, where the intersection of science, technology, and creativity gives rise to solutions that redefine the role of HDPE in the modern world.

Conclusion: A Dynamic Landscape of Possibilities

In conclusion, the future of HDPE sheets is a dynamic landscape of possibilities, fueled by innovation, technology, and a commitment to sustainability. From the integration of nanotechnology to the advent of smart materials and biodegradable solutions, HDPE sheets are not just evolving; they are pioneering new frontiers. As research initiatives continue to unravel the potential within this versatile material, HDPE sheets stand ready to shape the future of industries, from construction and healthcare to emerging technologies that are yet to be imagined. The journey of HDPE is not confined to its manufacturing process; it's an ongoing exploration of what can be achieved when ingenuity meets the limitless potential of this remarkable material.

No comments yet