Are you trying to find solutions to reduce expenses and increase efficiency in your manufacturing processes? You only need to look at internet CNC machining services! Businesses require simplified solutions that provide speed and precision in today's fast-paced world. That is precisely what Online CNC service provide: a hassle-free, practical substitute for conventional brick-and-mortar machine shops that provide top-notch machining services. Utilizing the possibilities of online CNC machining can provide you, regardless of size—whether you're a well-established player in the industry or a tiny startup—the competitive advantage you need. So let's explore how digital manufacturing can alter your production processes without breaking the bank as we delve into this fascinating field.

Benefits and Significance of CNC Machining Services Provided Online

With so many benefits to offer, online CNC machining services are essential in today's manufacturing environment. One cannot ignore the convenience element. From the convenience of your home or workplace, you can access a wide range of machining capabilities with online services. The days of obtaining bids or discussing project needs by going to actual machine shops are long gone.

Online CNC services offer unmatched efficiency and speed. These platforms' sophisticated software and automated procedures enable them to evaluate your design files rapidly and produce precise quotes in a matter of minutes. This guarantees quicker project response times in addition to saving you precious time.

Online CNC machining also makes cost reductions possible without sacrificing quality. When compared to traditional machine shops, online service providers frequently have fewer overhead expenses, allowing them to provide competitive pricing alternatives. Additionally, you can choose from a larger pool of manufacturers and suppliers, which will boost competition and further reduce costs.

Convenience, speed, efficiency, and cost savings are all advantages of online CNC machining services, and they are all important considerations in the very competitive manufacturing environment of today. Adopting digital manufacturing through online CNC services is a crucial first step towards optimizing productivity while lowering costs, regardless of the size of your company. Small businesses wishing to prototype new products or huge corporations seeking efficient production solutions at scale should embrace this approach.

Knowing CNC Machining: Materials and Procedures

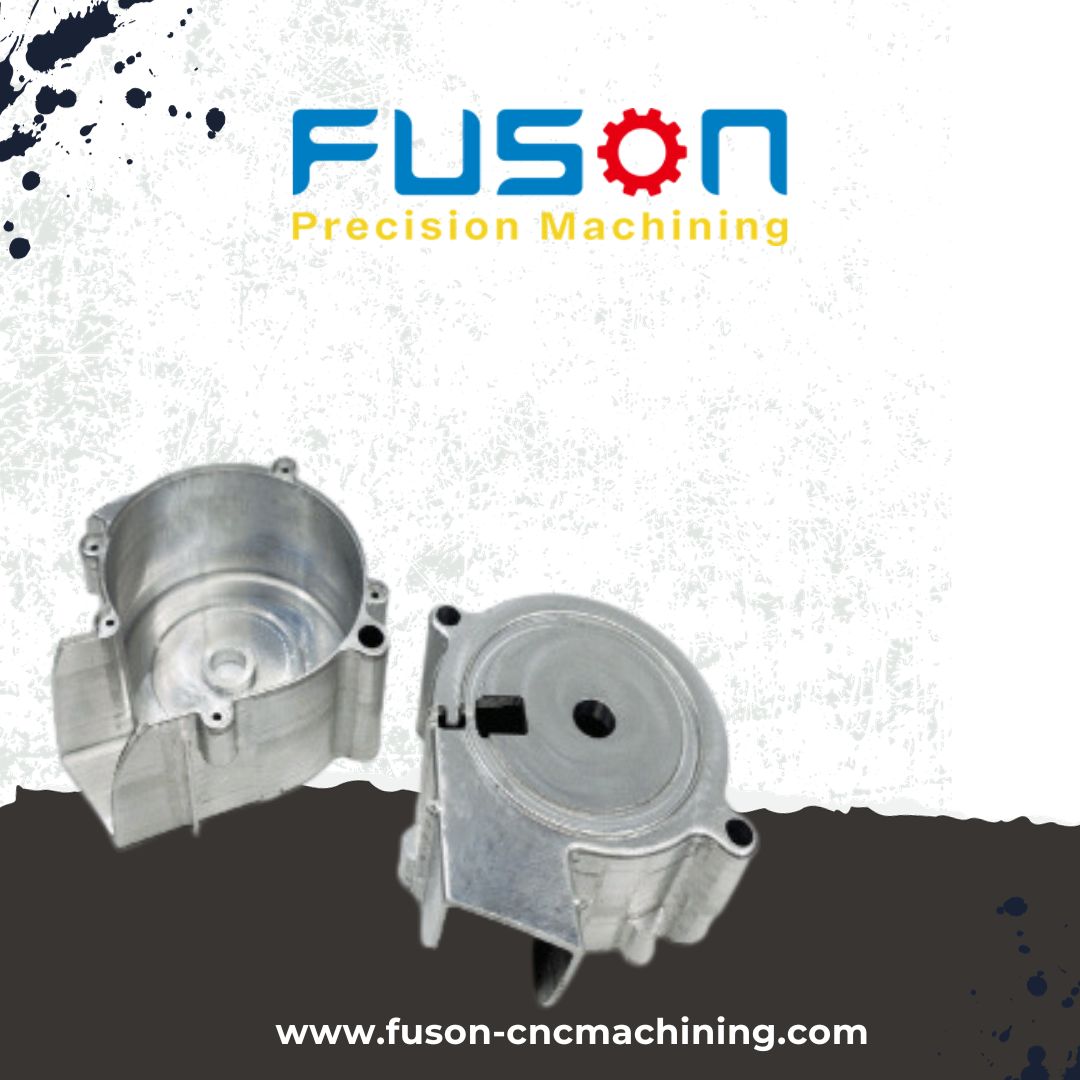

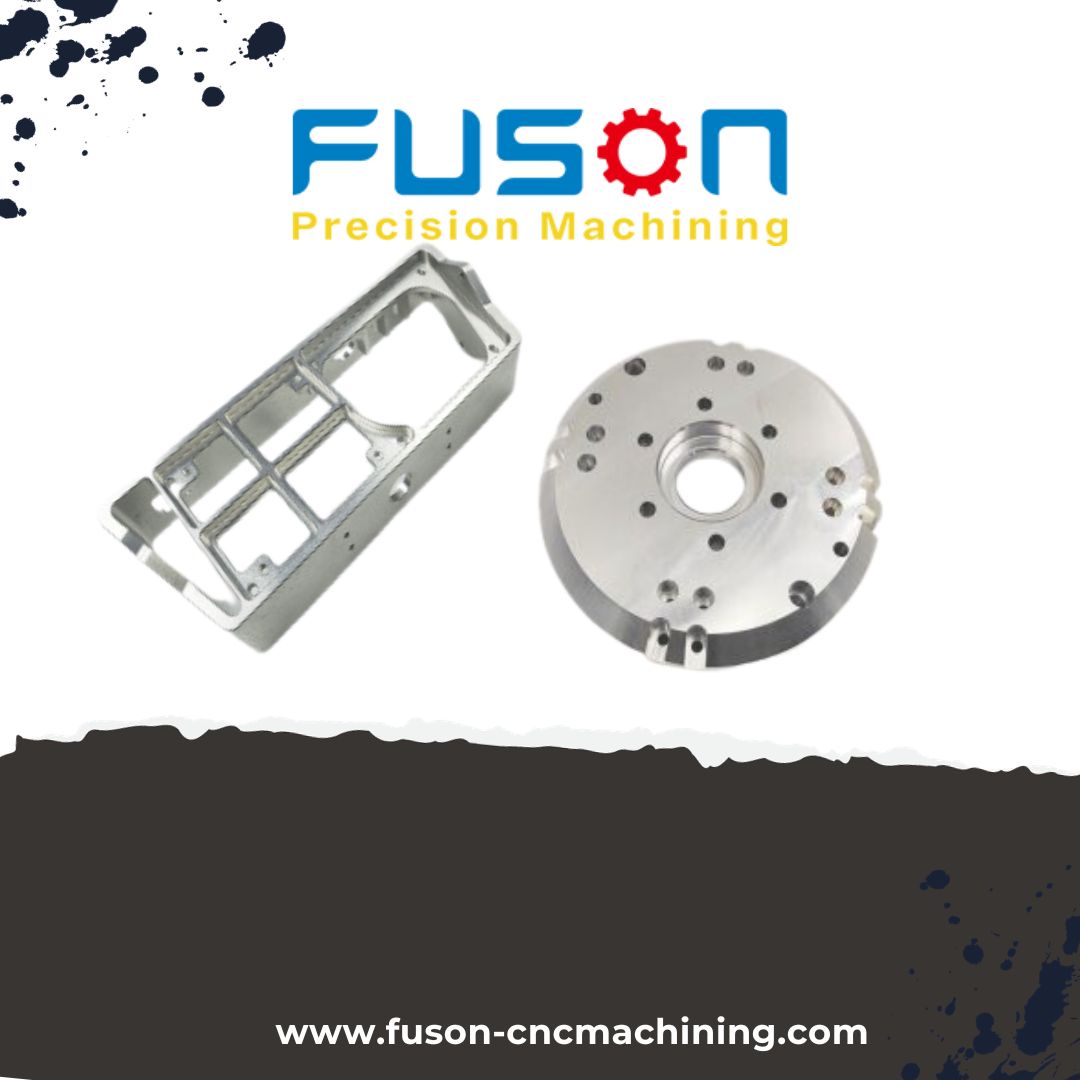

The manufacturing method known as CNC machining, or computer numerical control machining, makes use of automated tools and systems to create intricate and accurate parts. The manufacturing sector has seen a transformation because to this technology, which has increased productivity, accuracy, and versatility.

A number of crucial procedures are involved in CNC machining. The first stage is called design, during which engineers make a digital model of the desired part using specialist software. Programming is the next step, where professionals translate the design into instructions that a machine can understand. The CNC machine follows these instructions to carry out different operations including drilling, milling, turning, and cutting.

The materials used in CNC machining can change based on the particular needs of every project. Metals like titanium, steel, brass, and aluminum are examples of common materials. Because of its flexibility and durability, plastics like nylon and ABS (Acrylonitrile Butadiene Styrene) are also widely utilized.

Businesses may maximize productivity and cut costs by making informed decisions about their production needs by knowing the materials and procedures involved in CNC machining services provided online by machine shops like Fuson Precision Machining!

Typical Materials for CNC Machining

Selecting the appropriate material for CNC machining is essential to producing results that are of the highest caliber. Several typical materials are utilized a lot in CNC machining procedures. Let's take a closer look at a few of them.

Aluminum: Due to its remarkable strength-to-weight ratio, this versatile, lightweight material is used extensively in many different industries. Because it is easy to process, it is a wonderful alternative for precisely constructing intricate parts.

Steel: Due to its strength and durability, steel is a material that is frequently used in CNC machining. It is an excellent choice for applications needing robust components due to its strong resistance to corrosion and capacity to withstand elevated temperatures.

Plastics: From ABS and polycarbonate to nylon and acrylics, plastics offer a wide range of options for CNC machining applications. They are affordable, lightweight, and easily customizable to meet particular design specifications.

The desired qualities, financial limitations, and application requirements all play a role in the material selection process. Dealing with an online CNC service provider gives you access to a range of materials, making it easy for you to choose the best one for your project!

Advantages of Using CNC Machining Services Online

Any manufacturing organization must maximize efficiency and cost savings in the fast-paced, highly competitive business world of today. Online CNC machining services are useful in this situation. These services provide many advantages by utilizing the internet and technology, which can greatly increase production while cutting expenses.

Time Savings: By removing the need to look for nearby machine shops or wait for quotations, using online CNC machining services can help you save a lot of time. You can upload your design files and get fast quotations from several providers in just a few clicks. You may expedite manufacturing schedules and launch items more quickly thanks to this streamlined procedure.

Cost savings: High setup costs, wasteful material use, and labor expenditures are common with traditional machining techniques. Since online CNC machining services use automated methods to reduce errors and maximize material utilization, many of these overheads are eliminated. Because of the growing competition, their wide network of manufacturers also guarantees competitive prices.

Access to Cutting-Edge Technology: You may get cutting-edge equipment without having to buy pricey equipment by using an online CNC service. These platforms work with reliable producers who have sophisticated CNC machinery that can precisely produce intricate pieces.

Extensive Selection of Materials: Online CNC machining services provide an extensive selection of materials appropriate for many applications, regardless of your need for aluminum prototypes or production parts made of stainless steel or plastic. Their extensive assortment guarantees that your unique needs are effectively fulfilled.

Quality Assurance: To guarantee that every component produced satisfies stringent industry requirements, reputable Online machine shop services implement strong quality control methods throughout the manufacturing process.

You may rely on them for accuracy as well as consistency in terms of product quality, as their reputation is built on providing excellent products on time.

No comments yet