This article has provided an overview of robotic sortation and its benefits. It has also provided guidance on how to implement and enhance order fulfillment accuracy in your warehouse.

Businesses are constantly looking for methods to optimise their operations and improve efficiency in today's fast-paced environment. Warehouse management is one sector that has witnessed tremendous developments in recent years.

Businesses may now automate their order fulfilment operations and enhance accuracy while lowering labour costs thanks to the introduction of robotic sortation devices.

Optimizing warehouse operations is crucial to meet the growing demands of e-commerce and fast-paced supply chains. Robotics, powered by technologies like Autonomous Mobile Robots (AMRs), has emerged as a game-changing solution for warehouses and distribution centers.

This article delves into the world of robotic sortation, highlighting its benefits and providing guidance on how to implement and enhance order fulfillment accuracy in your warehouse.

What is Robotic Sorting?

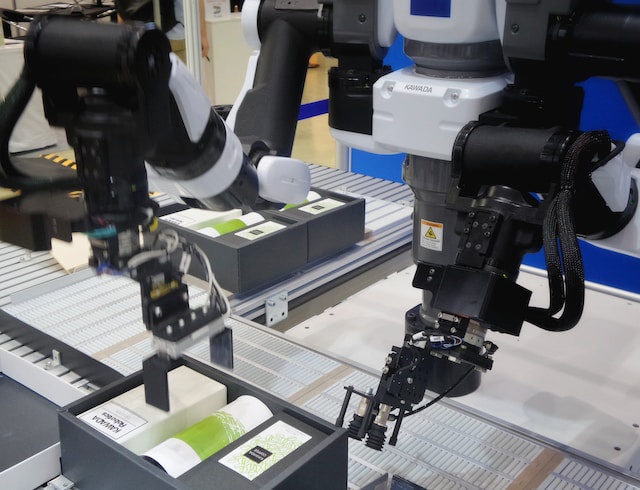

Robotics in sortation is a cutting-edge method of efficiently sorting inventory or orders within a warehouse or distribution center, relying on robotics, primarily Autonomous Mobile Robots (AMRs), to sort items, units, cases, or totes into orders.

This can involve sorting items into orders or preparing orders for packaging and shipping. Robotic sortation inherits the advantages of traditional automated sortation systems, including increased order accuracy, enhanced efficiency, and reduced labor costs, but it also brings its unique benefits, making it an ideal choice for modern warehouses.

Benefits of Robotic Sortation

In warehousing and e-commerce, the integration of robotic sortation systems has revolutionized the way businesses manage their inventory and fulfill customer orders. These advanced systems bring a plethora of advantages to the table, fundamentally altering the efficiency and precision of warehouse operations.

- Increased Order Accuracy:

In the quest for error-free order fulfillment, robotic sortation systems emerge as the unsung heroes. Renowned for their unwavering precision, they excel in minimizing errors in the order assembly process. With meticulous attention to detail, robotic arms and sensors ensure that every item is placed in the right order, resulting in a significant reduction in shipping mistakes. Ultimately, this translates into improved customer satisfaction, as recipients receive the correct products on time, leading to fewer returns and higher customer loyalty.

- Increased Efficiency:

The relentless pace of modern commerce demands efficiency at every turn. Robotic sortation systems rise to the occasion, processing orders at a remarkable speed, far surpassing the capabilities of manual labor. This efficiency boost becomes particularly critical during peak seasons when order volumes soar. With robotic precision and tireless work ethic, these systems not only expedite order fulfillment but also enable businesses to meet fluctuating demands seamlessly.

- Lower Labor Costs:

Labor costs can constitute a significant portion of a business's expenses. Robotic sortation systems provide an elegant solution by automating the labor-intensive sorting process. This reduction in reliance on manual labor not only leads to substantial cost savings but also frees up human resources for more strategic tasks, such as quality control and customer service. It's a win-win situation, where businesses cut costs while enhancing operational effectiveness.

- Improved Flexibility:

In the dynamic world of warehousing, adaptability is key. Robotic sortation systems are designed with versatility in mind, capable of seamlessly adjusting to changing operational requirements. Whether it's accommodating new product lines, altering sorting criteria, or responding to shifts in customer demands, these systems can be reconfigured with ease. This adaptability empowers businesses to stay agile in a competitive marketplace and swiftly respond to evolving needs.

- Reduced Floor Space:

Utilizing warehouse space efficiently is essential for businesses aiming to maximize storage capacity without the expense of expanding facilities. Robotic sortation systems are space-savvy, utilizing a compact footprint compared to traditional automated sortation solutions. This efficiency in space usage allows businesses to make the most of their available warehouse layout, optimizing storage while maintaining accessibility and workflow efficiency.

The incorporation of robotic systems isn't just a technological advancement; it's a strategic investment in the future of efficient and precise order fulfillment. Robotics in sortation systems offer a multitude of advantages, transforming warehouse and e-commerce order fulfillment centers into highly efficient and accurate operations.

How to Implement Robotic Sortation in Your Warehouse

Integrating robotics into your warehouse operations is a transformative step towards achieving higher efficiency and order accuracy. However, it's not a simple plug-and-play solution; it requires a meticulously planned implementation process. In this section, we'll guide you through the crucial steps to successfully implement robotic sortation in your warehouse, ensuring that it aligns with your specific needs and yields optimal results.

- Identify Your Needs:

Before diving into the world of robotic sortation, take the time to assess your warehouse's unique requirements. Consider factors such as the volume and variety of items you handle, your order processing times, and your long-term business goals. This assessment will guide you in selecting the most suitable robotic sortation system that fits seamlessly into your operations, addressing your pain points and objectives.

- Choose a Vendor:

Researching and selecting the right vendor is a pivotal decision in the implementation process. Look for vendors with a strong track record in providing robotic sortation solutions. Evaluate their offerings, ensuring they align with your identified needs. Additionally, prioritize vendors who offer comprehensive support, including installation, maintenance, and technical assistance, as a reliable partner can make a significant difference in your long-term success.

- Plan Your Implementation:

Developing a robust implementation plan is the cornerstone of a successful integration. Your plan should encompass every aspect of the process, starting with the installation of the robotic sortation system.

Consider how the system will seamlessly integrate with your existing warehouse infrastructure and systems, such as inventory management and order processing software.

Furthermore, anticipate potential challenges and create contingency plans to address any unforeseen issues that may arise during implementation. A well-structured plan minimizes disruptions and ensures a smooth transition.

- Train Your Staff:

While robotic sorting systems are designed for automation, your staff's familiarity with the technology is crucial for smooth operations. Invest in thorough training programs to educate your team on how to effectively operate and supervise the new robotic system. Emphasize safety protocols to prevent accidents and ensure that your staff is well-equipped to troubleshoot common issues. Staff training is not a one-time event; ongoing education will help your team adapt to the technology and maximize its potential.

- Monitor Performance:

Post-implementation, continuous monitoring of the robotic sortation system's performance is essential for fine-tuning and optimization. Collect data on its efficiency, accuracy, and any bottlenecks in the workflow. Use this information to make informed adjustments and improvements. Regularly review your system's performance against predefined key performance indicators (KPIs) to ensure that it is delivering the expected benefits. Stay agile and be prepared to make necessary adjustments as your warehouse evolves and grows.

How to Improve Order Fulfillment Accuracy with Robotic Sortation

Robotic sortation can significantly enhance order fulfillment accuracy. To maximize its benefits, consider the following tips:

- Use Barcodes:

Implementing barcode systems in conjunction with your robotic sortation system is akin to providing a precise roadmap for each item in your inventory. Barcodes enable real-time tracking of items and orders, from the moment they enter your warehouse to the point of dispatch. This not only ensures accurate sorting but also facilitates inventory management and order tracking. Barcodes reduce the chances of errors and discrepancies, enhancing overall operational efficiency.

- Optimize Workflows:

Streamlining workflows within your warehouse is crucial for harnessing the full potential of robotic sortation. Analyze and redesign your processes to ensure a seamless flow of items through the sortation system. Identify and eliminate bottlenecks and redundancies that may hinder efficiency. By optimizing workflows, you can capitalize on the speed and accuracy of robotic sortation, allowing orders to move swiftly from intake to dispatch, ultimately meeting customer expectations more effectively.

- Monitor Performance:

To maintain peak performance, it's essential to keep a watchful eye on your robotic sortation system's operations. Regular performance monitoring involves collecting data on sorting speed, error rates, and equipment reliability. By analyzing this data, you can identify patterns and pinpoint areas that require improvement or adjustments. This proactive approach allows you to fine-tune the system, ensuring it consistently operates at its best, which is essential in meeting the ever-evolving demands of modern e-commerce.

- Train Staff:

While automation is a cornerstone of robotic sortation, well-trained staff are equally vital. Continual education ensures that your employees are well-versed in the technology, from routine maintenance to troubleshooting. Staff who are confident in their ability to work alongside the robotic system can provide valuable oversight, rapidly addressing any unforeseen issues that may arise. Moreover, a well-trained team contributes to a safer work environment, reducing the risk of accidents and downtime.

With these strategies, you not only enhance the capabilities of your sortation system but also create a dynamic and adaptable warehouse environment.

Conclusion

Robotic sortation stands as a transformative solution in the order fulfillment and distribution industry, offering operations the means to significantly enhance efficiency, order accuracy, and throughput while simultaneously reducing labor costs. By following the steps outlined in this article, you can successfully implement robotic sortation in your warehouse, ultimately improving order fulfillment accuracy and bolstering your bottom line. Embrace the future of warehousing with robotic sortation technology.

No comments yet