In a world, where innovation and performance reign supreme, carbon fiber stands out as a symbol of cutting-edge technology and unparalleled strength. Its lightweight yet durable properties have revolutionized numerous industries, from aerospace marvels to high-performance sports equipment. However, amidst this allure lies a pervasive challenge: counterfeit products flooding the market.

Counterfeit carbon fiber products, or fake carbon fibers, imitate the appearance of real ones but are produced at a lower cost using materials like fiberglass, plastic, or low-quality carbon fiber remnants. This exploration delves into distinguishing between authenticity and imitation in the battle between real and fake carbon fiber, empowering consumers to make informed decisions in this realm.

Top of Form

Real Carbon fibers?

Real carbon fibers are thin strands of carbon atoms bonded together in a crystal alignment, forming a lightweight and incredibly strong material. They serve as the fundamental building blocks for carbon fiber composites used in various industries. The manufacturing process of real carbon fibers involves several key steps. It starts with selecting a precursor material, often polyacrylonitrile (PAN), and subjecting it to temperatures of 200°C to 400°C in an oxygen-deprived environment for stabilization. Subsequently, carbonization occurs, subjecting the material to even higher temperatures in an inert atmosphere (typically nitrogen) ranging from 1000°C to 3000°C to eliminate non-carbon atoms and leave behind pure carbon structures. Optionally, carbon fibers may undergo graphitization to further enhance their properties by subjecting them to temperatures up to 3000°C in a controlled environment, rearranging carbon atoms into a more ordered graphite-like structure.

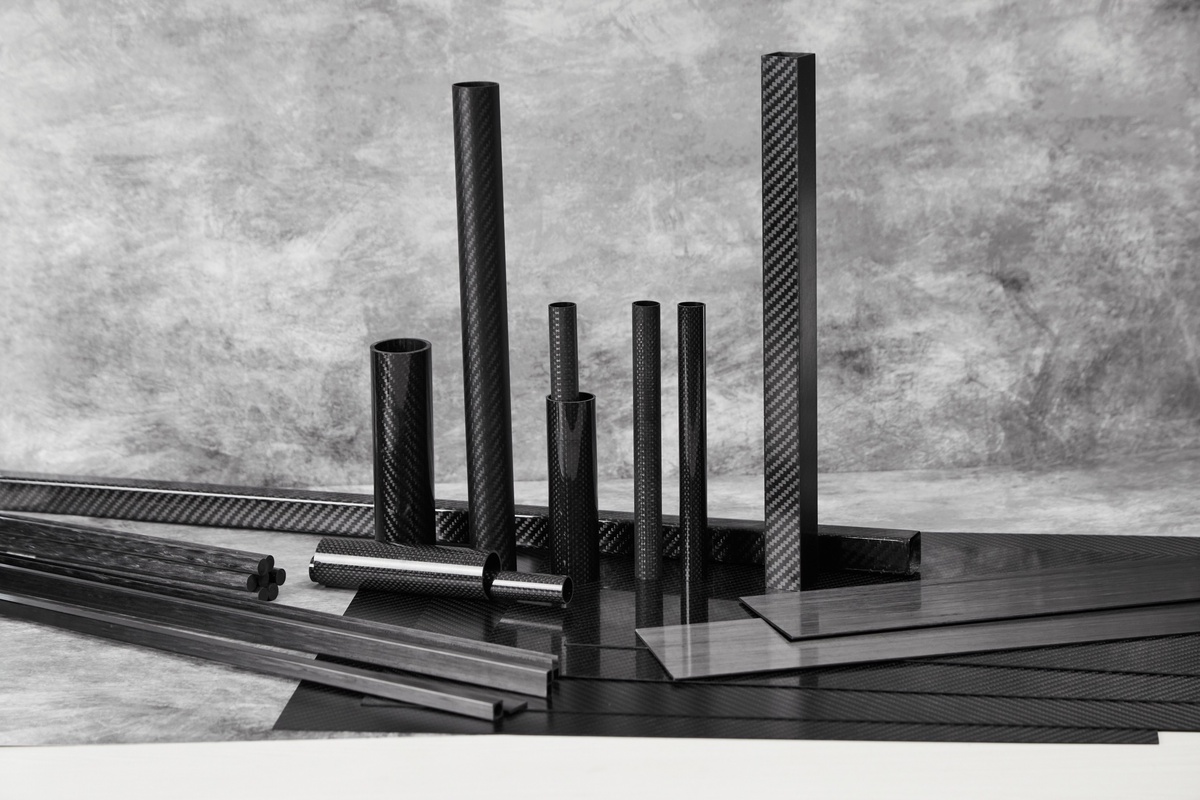

These high-performance carbon fibers serve as the basis for manufacturing various carbon fiber products, including sheets, rods, and tubes. Carbon fiber sheets are typically created by layering carbon fiber fabric or unidirectional tape and impregnating it with resin, then curing it under heat and pressure to form a solid composite sheet.

Carbon fiber tubes and rods are produced similarly, with layers of carbon fiber wrapped around a mandrel, infused with resin, and cured to form rigid structures. The meticulous control of thermal processes ensures that these carbon fiber products maintain exceptional strength, stiffness, and lightweight properties, making them ideal for a wide range of applications across industries.

Fake carbon fibers?

Fake carbon sheets, also known as imitation carbon fiber sheets, are produced using a manufacturing process aimed at replicating the visual aesthetics of real carbon fiber without delivering the same level of performance or quality.

Typically, these sheets are crafted using base materials like fiberglass, plastic, or low-quality carbon fiber remnants selected primarily for their cost-effectiveness and ease of processing. The manufacturing process involves molding or pressing the base material into sheets, often incorporating resin to improve cohesion and achieve a smoother surface finish. To mimic the distinctive weave pattern of real carbon fiber, a carbon fiber-like design is printed or painted onto the surface of the sheet. Surface treatments, such as applying a clear coat or glossy finish, may be employed to enhance the appearance and durability of the fake carbon sheets. Despite their resemblance to real carbon fiber, these imitation sheets lack the inherent strength, stiffness, and lightweight properties that characterize genuine carbon fiber composites.

Decoding Carbon Fiber: Recognizing Genuine vs Counterfeit Products

Carbon fiber has revolutionized various industries due to its exceptional properties and versatile applications. Understanding the characteristics of real carbon fiber and its manufacturing process is essential for identifying genuine products and distinguishing them from counterfeit ones.

Distinct Weave Patterns: Real carbon fiber exhibits a consistent and intricate weave pattern, often resembling a checkerboard or herringbone design. The weave should be tight and uniform across the surface, showcasing the precision of its manufacturing process. In contrast, fake carbon fiber often displays irregular or inconsistent weave patterns, lacking the precision and uniformity seen in genuine products.

Smooth Texture: Genuine carbon fiber has a smooth and glossy texture, reflecting light uniformly across its surface. The finish is flawless, with no visible imperfections such as bubbles, wrinkles, or irregularities. Counterfeit carbon fiber products may have visible imperfections, such as bubbles, wrinkles, or uneven surfaces, indicating a lower quality manufacturing process.

Weight and Strength: Authentic carbon fiber is renowned for its lightweight yet incredibly strong properties. When compared to similar-sized objects made from other materials, genuine carbon fiber products will typically feel lighter while maintaining exceptional strength and rigidity. Fake carbon fiber products may feel heavier than their genuine counterparts due to the presence of additional fillers or lower-grade materials used in the manufacturing process.

Resonance Test: Tapping or lightly knocking on a real carbon fiber object produces a distinct, high-pitched sound. This resonance is a result of the material's stiffness and low mass, indicating its authenticity. In contrast, fake carbon fiber products may produce a dull or muffled sound rather than the crisp, high-pitched tone characteristic of real carbon fiber.

Colored Carbon Fiber: Real carbon fiber cannot be colored or tinted, so any product marketed as "colored carbon fiber" is likely fake. The characteristic color of carbon fibers is due to the nature of graphitic materials, and it cannot be altered. Therefore, colored carbon fiber parts are a clear indicator of counterfeit products.

Genuine Manufacturers: When purchasing carbon fiber products, it's essential to buy from genuine manufacturers known for their quality and authenticity. Reputable companies adhere to strict quality control standards and use advanced manufacturing processes to ensure the integrity of their carbon fiber products. By choosing products from trusted manufacturers, consumers can have confidence in the authenticity and performance of their carbon fiber gear.

Conclusion

Understanding the distinctive characteristics of real carbon fiber and being aware of common indicators of fake products, such as weave patterns, texture, weight, resonance, colored fibers, and internal structure, can help consumers make informed purchasing decisions. Whether you're in the market for sporting equipment, automotive parts, or other carbon fiber products, knowing how to identify genuine carbon fiber is essential for ensuring quality and performance. Choosing products from genuine manufacturers adds an extra layer of assurance, allowing consumers to enjoy the benefits of authentic carbon fiber gear with confidence.

No comments yet