In the world of metal fabrication, the pursuit of precision and quality is paramount. To achieve these objectives, manufacturers often rely on a variety of specialized tools and machinery, one of which is the straightening machine. These machines play a crucial role in shaping and refining metal components, ensuring they meet exacting standards. This article explores the world of straightening machines, delving into their history, operation, applications, and the myriad advantages they offer to various industries.

- The Historical Evolution of Straightening Machines

The concept of straightening metal has roots dating back to ancient times, where skilled artisans utilized hammers and anvils to correct bends, twists, and deformities in metal objects. As metalworking evolved through the ages, the need for more efficient and precise straightening methods became evident. This led to the development of mechanical straightening machines.

The earliest mechanical straightening machines were relatively simple compared to their modern counterparts. However, they laid the foundation for the advanced, automated straightening machines used in today's metal fabrication industry.

- How Straightening Machines Operate

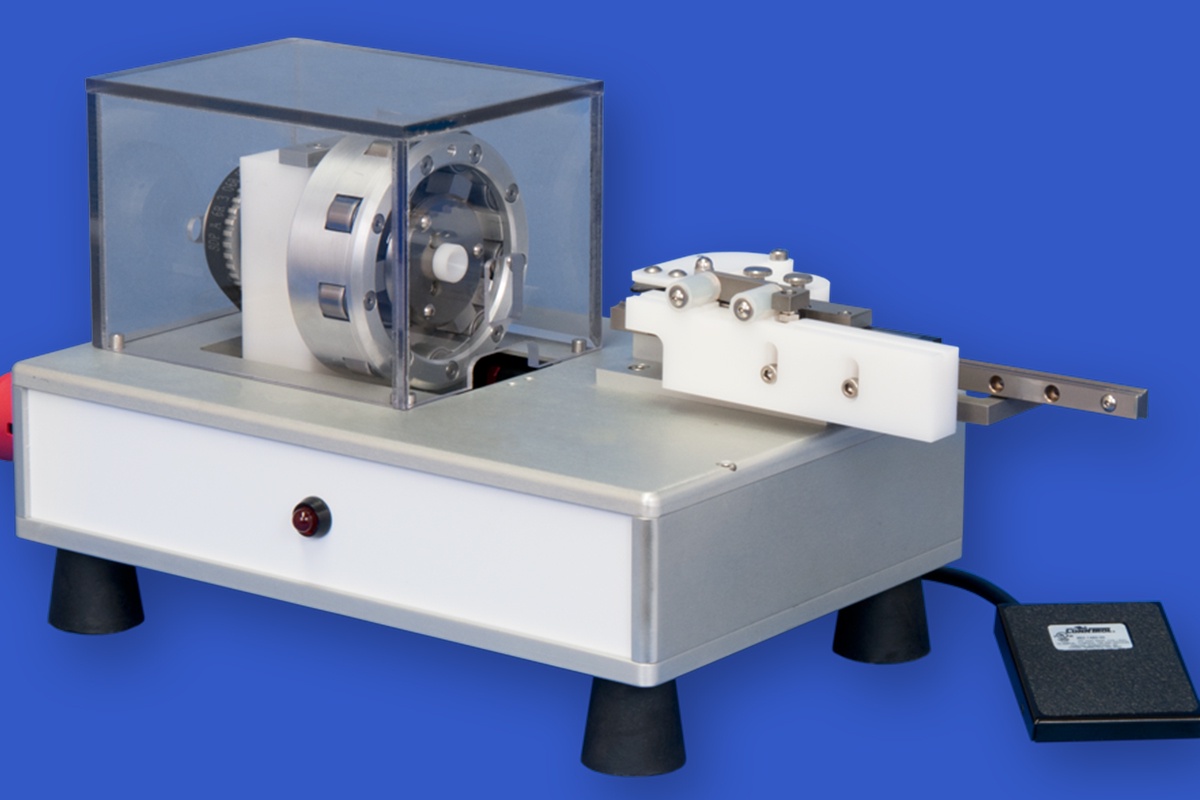

Straightening machines are specifically designed to rectify deformities in metal components, whether they are plates, bars, or tubes. The fundamental components of a straightening machine include:

a. Rollers or Dies: Straightening machines are equipped with multiple rollers or dies organized in sets. These rollers apply pressure to the metal workpiece as it passes through the machine, flexing and straightening it in the process.

b. Entry and Exit Guides: These guides ensure that the workpiece enters and exits the machine in a straight line, a crucial aspect of the straightening process.

c. The Straightening Process: As the metal workpiece progresses through the machine, the rollers or dies apply pressure at various points along its length, counteracting deformities and gradually straightening the material.

d. Adjustable Settings: Most modern straightening machines are equipped with settings that can be adjusted to fine-tune the straightening process. This enables operators to tailor the machine's operation to meet specific requirements.

- Applications of Straightening Machines

Straightening machines have diverse applications across a wide spectrum of industries due to their ability to produce straight and precisely shaped metal components. Some notable applications include:

a. Automotive Industry: Straightening machines are instrumental in ensuring the straightness of axles, drive shafts, chassis components, and other metal parts used in the automotive sector.

b. Manufacturing: Manufacturers use straightening machines to straighten metal bars, rods, and sheets that serve as raw materials for various production processes.

c. Construction: Construction companies rely on straightening machines to ensure that metal reinforcements, rebars, and structural components are straight and aligned, thereby enhancing the structural integrity of buildings.

d. Aerospace: The aerospace industry extensively employs straightening machines to produce straight and defect-free metal components used in aircraft manufacturing, where precision is a critical factor.

e. Steel and Metal Fabrication: Straightening machines play a pivotal role in the steel and metal fabrication industry by ensuring that materials are straight and devoid of deformities before being used in a wide array of applications.

- The Advantages of Straightening Machines

Straightening machines offer numerous advantages to manufacturers and industries:

a. Precision: Straightening machines are capable of achieving high levels of precision, ensuring that metal products meet stringent tolerances and quality standards.

b. Efficiency: By significantly reducing the time and labor required to straighten metal workpieces, these machines enhance efficiency and reduce production costs.

c. Material Savings: Straightening machines help minimize material wastage, thereby lowering costs associated with scrap and contributing to sustainability.

d. Enhanced Structural Integrity: These machines improve the structural integrity and durability of metal components, making them more reliable and safer for various applications.

e. Customization: The adjustability of straightening machines allows manufacturers to customize the straightening process to meet specific design requirements, further expanding their utility in metal fabrication.

Conclusion

Straightening machines are pivotal tools in the metal fabrication industry, providing precision, efficiency, and quality control. These machines ensure that metal products are free from deformities and are utilized across a multitude of sectors, including automotive, aerospace, construction, and manufacturing. As technology continues to advance, straightening machines will continue to play a critical role in the pursuit of excellence in metal fabrication and manufacturing.

No comments yet