1. Why is Mechanical Drafting Required and Important?

Mechanical drafting is crucial in the design and manufacturing process as it serves as a bridge between conceptual ideas and the actual creation of a product. Here are some reasons why it is essential:

- Precision and Accuracy: Mechanical drafting ensures that every detail of a design is accurately represented, minimizing errors during production.

- Communication: It serves as a universal language for engineers, architects, and manufacturers to communicate design specifications.

- Visualization: Drafts provide a visual representation of complex ideas, allowing stakeholders to understand the design before production.

- Cost Reduction: By identifying issues early in the design phase, mechanical drafting helps reduce the likelihood of costly errors during manufacturing.

2. How Does Mechanical Drafting Work and What is the Process?

Mechanical drafting involves several steps:

- Conceptualization: Engineers conceptualize the design, considering functionality, materials, and dimensions.

- Sketching: Initial sketches are created, either by hand or using computer-aided design (CAD) software.

- Detailed Drafting: Detailed drawings are developed, including specifications, tolerances, and material requirements.

- Review and Approval: Designs are reviewed by relevant stakeholders, and necessary changes are incorporated.

- Finalization: Once approved, final drafts are created, ready for manufacturing.

3. Costing of Opting for a Mechanical Drafting Company:

The cost varies based on factors like complexity, size, and scope of the project, as well as the reputation and expertise of the drafting company. It's crucial to get detailed quotes and understand the services included.

4. Standards and Codes:

Mechanical drafting must adhere to industry standards and codes. Examples include ASME (American Society of Mechanical Engineers) standards and ISO (International Organization for Standardization) codes.

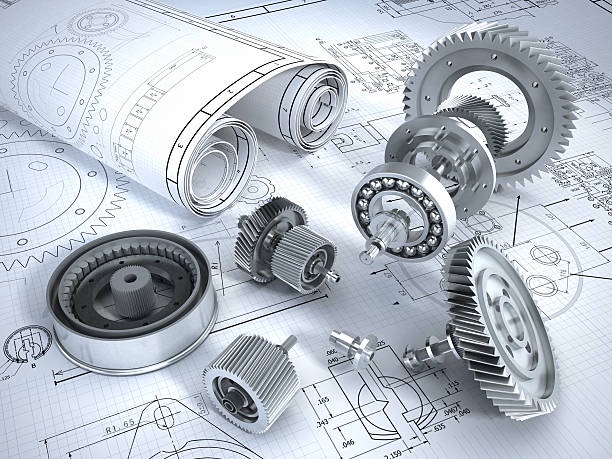

5. Examples of Mechanical Drafting:

Examples include architectural plans, machine drawings, assembly drawings, and exploded views of products.

6. Quality Control and Assurance:

Quality control ensures that drafts meet specified standards. This involves regular checks, reviews, and testing to identify and rectify any issues. Quality assurance involves implementing processes to prevent errors.

7. Why Choose Edanbrook Consultancy Services:

Edanbrook Consultancy Services stands out for several reasons:

- Expertise: A team of highly skilled and experienced draftsmen and engineers.

- Compliance: Adherence to international standards and codes.

- Innovation: Integration of the latest technologies and industry best practices.

- Quality Assurance: Rigorous quality control processes to ensure precision and accuracy.

- Custom Solutions: Tailored services to meet specific client needs.

In conclusion, mechanical drafting is indispensable in the design and manufacturing process, ensuring precision, accuracy, and effective communication. Opting for a reputable consultancy service like Edanbrook ensures the highest quality and innovative solutions.

No comments yet