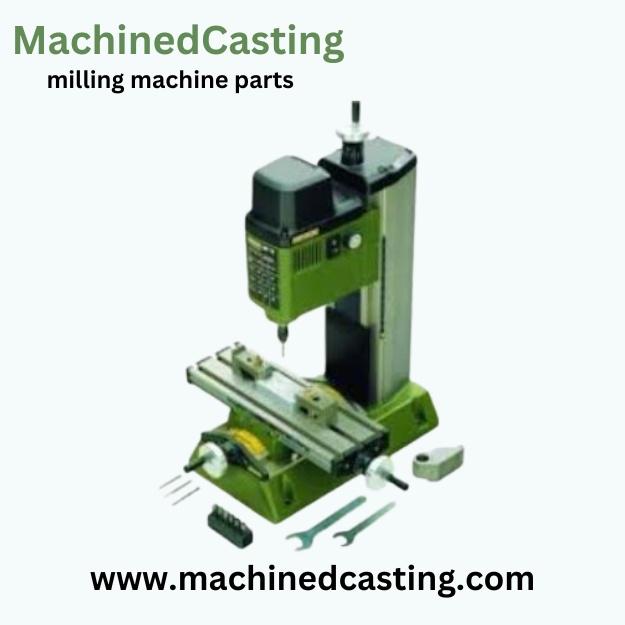

Milling machines are essential tools in various industries, from manufacturing to metalworking and beyond. Understanding their intricate parts and functions is crucial for efficient operation and maintenance. In this guide, we'll delve into the key milling machine parts, providing a detailed overview to aid both beginners and seasoned professionals.

-

Base: The base is the foundation of the milling machine parts, providing stability and support for all other components. Typically made of cast iron, it ensures vibration-free operation by absorbing and dampening any machine-generated vibrations.

-

Column: Mounted on the base, the column houses the spindle assembly and supports the vertical movement of the saddle and knee. It's crucial for maintaining the alignment and rigidity of the machine during operation.

-

Knee: The knee is a vertically adjustable component that supports the saddle and table. Its precise movement enables vertical positioning of the workpiece and cutting tools, allowing for accurate milling operations.

-

Saddle: Mounted on the knee, the saddle provides horizontal movement along the length of the table. It supports the table and workpiece during machining, facilitating precise positioning for horizontal milling operations.

-

Table: The table is the work surface where the workpiece is secured during milling. It can be moved longitudinally, transversely, and vertically to accommodate various machining requirements. T-slots on the table allow for secure clamping of workpieces and accessories.

-

Spindle: The spindle is the rotating shaft that holds the cutting tool and performs the actual milling operation. It can be driven by various means, such as a motor or manual power feed, and is capable of rotating at different speeds to accommodate different materials and cutting requirements.

-

Cutting Tool: The cutting tool is the business end of the milling machine, responsible for shaping the workpiece to the desired dimensions and surface finish. Various types of cutting tools, such as end mills, face mills, and drills, are used depending on the specific machining task.

Conclusion: Mastering the milling machine parts is essential for achieving precision and efficiency in machining operations. By understanding the roles and functions of each part, operators can maximize the machine's capabilities while ensuring safe and reliable performance. Regular maintenance and proper care of these components are also vital for prolonging the machine's lifespan and maintaining optimal performance.

No comments yet