Thread ring gauges are essential tools in precision engineering, where accuracy is everything. These small yet mighty instruments ensure that threaded components fit together seamlessly, facilitating the smooth operation of countless machines and devices across various industries. Behind these essential tools lie skilled manufacturers who meticulously craft them to exacting standards. In this guide, we delve into the world of thread ring gauge manufacturers, exploring their role, the manufacturing process, key considerations, and how they contribute to seamless operations in diverse sectors.

Understanding Thread Ring Gauges

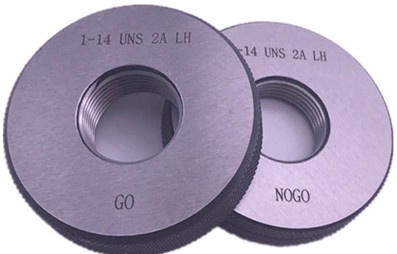

Thread ring gauges are precision tools used to measure threaded parts' pitch diameter and functional thread. They consist of an internal and external ring with accurately machined threads to verify the pitch diameter and ensure conformity to specified tolerances. These gauges are critical in quality control, ensuring that threaded components meet precise specifications and standards.

The Importance of Choosing the Right Manufacturer

Selecting the right thread ring gauge manufacturer is paramount to ensure the quality, accuracy, and reliability of the gauges. Here are some key factors to consider:

Expertise and Experience:

Look for manufacturers with a proven track record of expertise and experience in producing high-quality thread ring gauges. Experienced manufacturers are more likely to have a deep understanding of industry standards, materials, and manufacturing techniques, ensuring the reliability and accuracy of their gauges.

Precision Manufacturing Processes:

Choose manufacturers that employ state-of-the-art manufacturing processes and equipment to ensure the precision and consistency of their gauges. Advanced machining techniques, such as CNC machining, grinding, and EDM (Electrical Discharge Machining), contribute to the production of gauges with tight tolerances and superior accuracy.

Quality Assurance:

Ensure that the manufacturer has robust quality assurance processes in place to maintain the highest standards of quality and accuracy. This includes comprehensive inspection and testing procedures throughout the manufacturing process to detect any deviations from specifications and ensure the integrity of the gauges.

Customization Capabilities:

Opt for manufacturers that offer customization options to tailor thread ring gauges to specific requirements. Whether it's custom thread profiles, sizes, or materials, the ability to customize gauges ensures they meet the unique needs of different applications and industries.

The Manufacturing Process

The manufacturing process of thread ring gauges involves several precise steps to ensure the quality and accuracy of the final product:

Material Selection: High-quality materials, such as tool steel or carbide, are selected based on the application requirements and desired durability.

Machining: The selected material is machined using advanced CNC equipment to create the internal and external threads of the ring gauges with utmost precision.

Grinding: Grinding processes are employed to refine the threads and achieve the desired surface finish and dimensional accuracy.

Heat Treatment: The gauges undergo heat treatment processes, such as hardening and tempering, to enhance their hardness, durability, and resistance to wear and deformation.

Final Inspection: Each gauge undergoes rigorous inspection using precision measuring instruments to verify its dimensions, thread profiles, and conformity to specified tolerances.

Certification: Once the gauges pass inspection, they are certified and marked with relevant information, such as size, thread type, and tolerance class, ensuring traceability and compliance with standards.

Key Considerations for Users

When using thread ring gauges, it's essential to keep the following considerations in mind to ensure accurate measurements and optimal performance:

Proper Handling: Handle gauges with care to avoid damage to the threads or surfaces, which could affect their accuracy.

Regular Calibration: Periodic calibration ensures that gauges maintain their accuracy over time, especially in demanding or high-volume applications.

Storage Conditions: Store gauges in a clean, dry environment away from moisture, dust, and corrosive substances to prevent damage and maintain their integrity.

Usage Guidelines: Follow manufacturer-recommended guidelines for using thread ring gauges, including proper insertion techniques and torque values, to obtain accurate measurements and prolong gauge life.

Conclusion

In conclusion, thread ring gauges play a crucial role in ensuring the quality, reliability, and performance of threaded components across various industries. Choosing the right manufacturer is essential to obtain high-quality gauges that meet stringent standards and specifications. By understanding the manufacturing process, key considerations, and the role of manufacturers, users can make informed decisions and maximize the value of thread ring gauges in their applications.

For premium-quality thread ring gauges crafted with precision and expertise, trust Gaugestools – your reliable partner in precision measurement solutions.

No comments yet