Welcome to our comprehensive guide on hydraulic pump leaks! In this blog post, we will delve into the intricate world of hydraulic pumps, exploring their significance in various industries, the potential causes of leaks, methods for detection, repair techniques, and preventive measures.

So, buckle up and get ready to enhance your understanding of hydraulic pump maintenance and ensure the optimal performance of your equipment.

Hydraulic pumps are pivotal in numerous industries, powering machinery and equipment essential for various operations. From construction and manufacturing to automotive and aerospace sectors, the efficient functioning of hydraulic pumps is instrumental in driving productivity and performance. However, the occurrence of hydraulic pump leaks can significantly impact the overall efficiency and safety of equipment, making it imperative to address this issue promptly and effectively.

II. Understanding Hydraulic Pumps

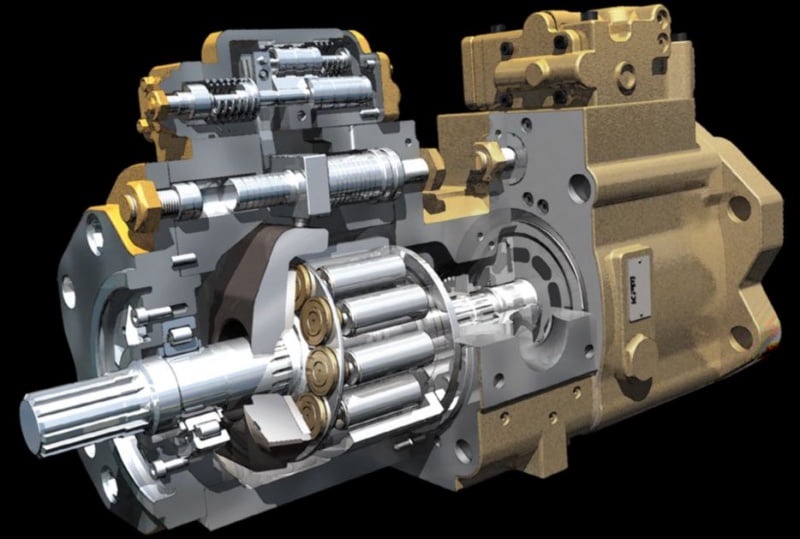

Before delving into the complexities of hydraulic pump leaks, let's establish a foundational understanding of these critical components. Hydraulic pumps are mechanical devices designed to generate fluid flow within a hydraulic system, facilitating power transmission to different machinery parts. These pumps come in various types, including gear, piston, and vane pumps, each serving specific purposes in different applications. Maintaining the efficiency of hydraulic pumps is essential to ensure the seamless operation of equipment and machinery across diverse industries.

III. Causes of Hydraulic Pump Leaks

1. Wear and Tear on Seals and Gaskets:

The primary reason behind hydraulic pump leaks often boils down to the natural wear and tear of seals and gaskets. These vital components, subjected to continuous exposure to high-pressure hydraulic fluids, gradually degrade over time. The resulting deterioration compromises their integrity, leading to fluid seepage and the potential for leaks. As these seals and gaskets lose their resilience, the hydraulic system becomes susceptible to leakage, necessitating regular inspection and replacement to maintain optimal functionality.

2. Contamination from External Factors:

The infiltration of external contaminants poses a significant threat to hydraulic systems, potentially resulting in pump leaks. Dirt, debris, and various particulate matter can infiltrate the hydraulic system through seals or other access points. Once inside, these contaminants compromise the pump's integrity, hindering its smooth operation and potentially causing leaks. Preventative measures, such as regular system checks, proper sealing, and maintaining a clean working environment, are crucial to minimizing the risk of contamination-related leaks.

3. High Pressure Leading to Component Failure:

Excessive pressure within the hydraulic system exerts undue stress on pump components, increasing the likelihood of failure and subsequent leaks. The sustained high pressure strains the pump, causing components to weaken or malfunction over time. This stress-induced failure can manifest as cracks, fractures, or ruptures in the pump assembly, resulting in leaks. Proper maintenance practices and adhering to recommended pressure limits are essential in preventing component failure due to excessive pressure, thereby reducing the risk of hydraulic pump leaks.

IV. Detecting Hydraulic Pump Leaks

Accurately identifying hydraulic pump leaks is crucial for initiating timely repairs and preventing further damage to equipment. Here are some effective methods for detecting leaks:

Visual Inspection for Oil Stains or Puddles:

Regular visual inspections of the equipment and its surrounding areas can reveal telltale signs of hydraulic fluid leaks, such as oil stains or puddles, indicating the presence of a leak.

Monitoring Fluid Levels and Pressure Readings:

Tracking fluid levels and pressure readings in the hydraulic system can help in identifying fluctuations that may signify leaks or pressure-related issues.

Using Leak Detection Dyes:

Application of specialised leak detection dyes can aid in pinpointing the exact location of hydraulic pump leaks, facilitating targeted repair efforts.

V. Impact of Hydraulic Pump Leaks

The ramifications of hydraulic pump leaks extend beyond mere operational disruptions, encompassing broader implications for equipment performance and maintenance costs:

Decreased System Efficiency:

Leakage of hydraulic fluid compromises the system's overall efficiency, potentially leading to reduced performance and productivity.

Increased Maintenance Costs:

Addressing hydraulic pump leaks and their associated effects often means heightened maintenance expenditures, impacting the overall operational budget.

Potential Safety Risks for Equipment Operators:

Leakage of hydraulic fluid can create hazardous working conditions, posing safety risks for equipment operators and personnel in the vicinity.

VI. Repairing Hydraulic Pump Leaks

Effective repair of hydraulic pump leaks is essential for restoring the optimal functionality of equipment. Key repair techniques include:

Replacing Worn-Out Seals and Gaskets:

Identifying and replacing worn-out or damaged seals and gaskets is crucial for preventing further fluid leakage from the hydraulic pump.

Flushing the System to Remove Contaminants:

Thoroughly flushing the hydraulic system to eliminate contaminants and impurities can mitigate the risk of leaks and enhance overall system integrity.

Addressing Pressure-Related Issues:

Systematically addressing pressure-related issues, such as regulating pressure settings and ensuring the integrity of pressure control mechanisms, can prevent future leaks.

VII. Preventing Hydraulic Pump Leaks

Proactive measures to prevent hydraulic pump leaks are integral to maintaining equipment reliability and longevity. Consider the following preventive strategies:

Regular Maintenance Schedules:

Establishing routine maintenance schedules for hydraulic systems, including inspections, fluid checks, and component assessments, can pre-emptively address potential issues and mitigate the risk of leaks.

Using High-Quality Replacement Parts:

Utilising high-quality, OEM-recommended replacement parts for hydraulic pumps and associated components can bolster system resilience and minimise the likelihood of leaks.

Taking Proactive Measures to Reduce Contamination Risks:

Implementing measures to minimise the ingress of external contaminants into the hydraulic system, such as effective filtration and sealing practices, can safeguard against potential leaks.

Conclusion

In conclusion, the effective management of hydraulic pump leaks is essential for ensuring equipment's sustained performance and safety in diverse industrial settings. By understanding the causes, detection methods, repair techniques, and preventive measures associated with hydraulic pump leaks, individuals and businesses can proactively address these challenges and uphold the efficiency of their hydraulic systems.

As we conclude this informative discussion, it is paramount to emphasise the significance of prompt action in addressing hydraulic pump leaks. By prioritising maintenance, leveraging effective detection methods, and implementing preventive measures, businesses can fortify their hydraulic systems against potential leaks and sustain operational excellence.

We hope this comprehensive guide has equipped you with valuable insights into the world of hydraulic pumps and the critical considerations surrounding leaks and maintenance. Remember, vigilance and proactive maintenance are the keys to ensuring uninterrupted equipment performance and operational reliability when it comes to hydraulic pump leaks.

So, until next time, stay informed, stay proactive, and keep those hydraulic pumps leak-free!

No comments yet