Introduction

In the intricate world of pharmaceutical manufacturing, precision is paramount. From the formulation of life-saving drugs to the delicate intricacies of packaging, every step demands an environment that ensures the highest standards of quality and purity. Enter nitrogen – the unsung hero quietly revolutionizing pharmaceutical production processes. In this blog, we embark on a journey through the growing role of nitrogen in pharmaceutical manufacturing, exploring its multifaceted contributions and the profound impact it has on ensuring the safety, efficacy, and integrity of pharmaceutical products.

Pharmaceutical manufacturers are increasingly turning to nitrogen as an indispensable tool in their quest for excellence. Beyond its inert nature, nitrogen serves a plethora of purposes critical to the pharmaceutical industry. As we delve into the nuances of nitrogen applications, we will uncover its influence on enhancing drug stability, preventing contamination, and safeguarding the overall integrity of pharmaceutical processes.

What does industrial nitrogen mean?

Industrial nitrogen refers to nitrogen gas produced and utilized in various industrial applications. Nitrogen is a colorless, odorless, and inert gas that makes up a significant portion of the Earth's atmosphere. In industrial settings, nitrogen is separated and purified for specific applications, leveraging its inert properties and diverse characteristics.

Key characteristics and applications of industrial nitrogen include:

- Inert Atmosphere: Nitrogen is often used to create inert atmospheres in industrial processes, particularly in manufacturing and storage. Its inert nature helps prevent oxidation, combustion, and degradation of sensitive materials and products.

- Blanketing and Padding: Nitrogen is commonly employed in processes where maintaining a controlled environment is crucial. It is used for blanketing and padding to displace oxygen and other gases, reducing the risk of explosions or degradation.

- Food and Beverage Industry: In the food and beverage industry, nitrogen is utilized for food packaging. Nitrogen flushes oxygen out of packaging, extending the shelf life of products and preventing spoilage.

- Pharmaceutical Manufacturing: Nitrogen plays a vital role in pharmaceutical manufacturing. It is used to create inert atmospheres during the production of drugs and to prevent oxidation and degradation of sensitive pharmaceutical compounds.

- Welding and Metal Processing: In welding, nitrogen is sometimes used as a shielding gas to protect molten metal from atmospheric contamination. It is also employed in metal processing to prevent oxidation during heat-treating processes.

- Electronics Manufacturing: Nitrogen is essential in electronics manufacturing, where it is used in various processes such as soldering and wave soldering to prevent oxidation and ensure the quality of electronic components.

- Oil and Gas Industry: In the oil and gas sector, nitrogen is utilized for various purposes, including well stimulation, enhanced oil recovery, and purging pipelines to remove flammable gases and prevent explosions.

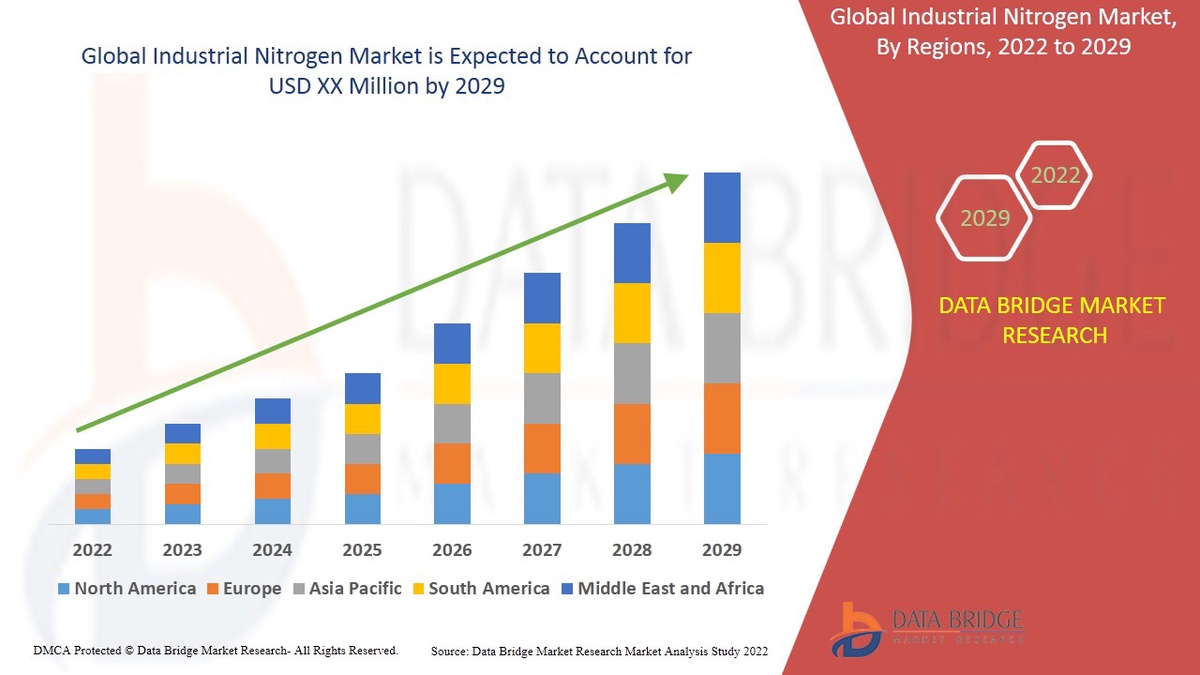

Expansion rate in industrial nitrogen market

- In the forecast period spanning from 2022 to 2029, the industrial nitrogen market is poised for substantial growth, according to an analysis conducted by Data Bridge Market Research. Projections indicate a robust Compound Annual Growth Rate (CAGR) of 7.90%, signifying a significant expansion in market size and opportunities.

- The anticipated growth is attributed to the increasing adoption of nitrogen across diverse industrial sectors, driven by its versatile applications and critical role in ensuring safety, quality, and efficiency in various processes. Industries such as pharmaceuticals, electronics manufacturing, food and beverages, and oil and gas are expected to contribute significantly to this upward trajectory. The rising demand for nitrogen in inerting atmospheres, preventing oxidation, and enhancing product stability underscores its indispensable nature in industrial applications. Data Bridge Market Research's comprehensive analysis takes into account various market dynamics, trends, and factors influencing the growth of the industrial nitrogen market, providing stakeholders with valuable insights to make informed decisions in this dynamic and evolving landscape.

Growing Role of Nitrogen in Pharmaceutical Manufacturing

- The pharmaceutical manufacturing landscape is experiencing a transformative shift with the growing acknowledgment of nitrogen's pivotal role in enhancing precision and ensuring the integrity of the entire production process. Nitrogen, a colorless and inert gas, has emerged as a silent catalyst in pharmaceutical manufacturing, contributing significantly to various critical aspects. This blog delves into the burgeoning significance of nitrogen in the pharmaceutical industry, uncovering its multifaceted applications and the profound impact it has on the safety, efficacy, and overall quality of pharmaceutical products.

- In the pharmaceutical realm, where precision is paramount and product quality is non-negotiable, nitrogen has become an indispensable ally. One of its primary applications lies in creating inert atmospheres during the manufacturing of drugs. This ensures that sensitive pharmaceutical compounds are shielded from the detrimental effects of oxygen, preventing oxidation and degradation that could compromise the efficacy of the final product.

- Beyond its role in maintaining inert environments, nitrogen plays a crucial part in preventing contamination during various stages of pharmaceutical production. It acts as a protective shield, safeguarding the integrity of pharmaceutical formulations from unwanted reactions or impurities that could compromise the safety of medications.

- Nitrogen's influence extends to the packaging stage, where it is employed to create controlled atmospheres that prolong the shelf life of pharmaceutical products. By displacing oxygen in packaging, nitrogen helps prevent oxidative reactions that could lead to the degradation of drugs, ensuring that medications reach end-users with their potency intact.

- Moreover, as pharmaceutical manufacturing processes become more sophisticated and precise, nitrogen finds applications in enhancing the efficiency of equipment and processes. Its use in processes such as freeze-drying and inerting reaction vessels contributes to the overall quality and consistency of pharmaceutical products.

To gain more knowledge about market visit

https://www.databridgemarketresearch.com/reports/global-industrial-nitrogen-market

Conclusion

In conclusion, the growing role of nitrogen in pharmaceutical manufacturing is a testament to its versatility and reliability in ensuring the highest standards of quality and safety. As the pharmaceutical industry continues to evolve, nitrogen stands as a fundamental element in the pursuit of precision, contributing significantly to the production of medications that meet the stringent demands of regulatory compliance and patient well-being. This blog aims to unravel the layers of nitrogen's involvement in pharmaceutical manufacturing, shedding light on its transformative impact on an industry dedicated to improving global health.

No comments yet