Introduction

In the bustling world of food production and packaging, precision and efficiency are paramount. Flour, a staple in countless culinary creations, is no exception. The flour packing machine is a game-changing piece of equipment that revolutionizes the packaging process. In this article, we will delve into the significance of flour packing machines, their operation, benefits, and the impact they have on the food industry.

The Flour Packing Machine: A Marvel of Automation

Automating the Packaging Process

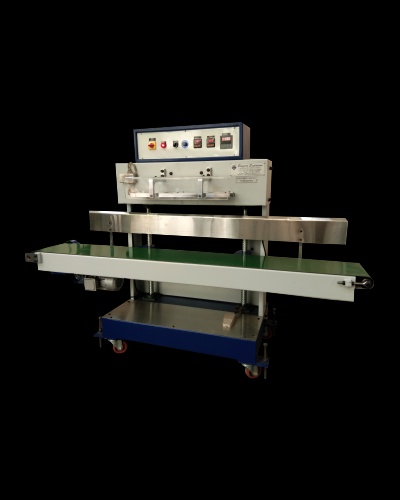

Flour packing machine is automated systems designed to efficiently and accurately package flour into bags or containers. These machines have become indispensable in flour mills and food production facilities, streamlining what was once a labor-intensive and error-prone process.

How Flour Packing Machines Work

Precision in Action

Flour packing machines work with remarkable precision. They typically consist of a conveyor system that transports the flour to a weighing station. Here, the flour is weighed to the desired amount with extreme accuracy, ensuring that each package contains the correct quantity. The flour is then dispensed into bags or containers, which are sealed securely.

Benefits of Using Flour Packing Machines

Efficiency and Consistency

Flour packing machines offer a plethora of benefits to food producers:

- Speed and Efficiency: These machines can package flour at a significantly faster rate than manual methods, increasing production output.

- Accuracy: Precision weighing and filling reduce the likelihood of overfilling or underfilling, ensuring consistency across packages.

- Labor Savings: Flour packing machines require minimal human intervention, leading to reduced labor costs and the reallocation of personnel to other critical tasks.

- Reduced Waste: Accurate portioning minimizes product waste, contributing to cost savings and environmental sustainability.

- Improved Hygiene: Automated systems adhere to strict hygiene standards, reducing the risk of contamination.

Customization and Adaptability

Meeting Diverse Packaging Needs

Flour packing machines are adaptable and can cater to various packaging needs. They can accommodate different bag sizes, types, and packaging materials. This flexibility allows producers to meet market demands and consumer preferences effectively.

Impact on the Flour Industry

Enhancing Flour Production and Quality

The adoption of flour packing machines has had a profound impact on the flour industry:

- Increased Production: Flour mills can produce larger quantities of flour in less time, meeting the ever-growing demand for this staple ingredient.

- Consistent Quality: With precise weighing and packaging, flour quality remains consistent, leading to satisfied customers and brand loyalty.

- Competitive Edge: Flour producers who invest in automation gain a competitive edge by optimizing production and reducing costs.

- Market Expansion: The ability to efficiently package and distribute flour opens doors to new markets, both domestically and internationally.

Sustainability in Flour Packaging

Balancing Efficiency with Environmental Responsibility

In today's eco-conscious world, sustainability is a paramount concern. Flour packing machines can contribute to sustainability efforts in several ways:

- Reduced Packaging Waste: Accurate portioning minimizes excess packaging, reducing the environmental impact.

- Energy Efficiency: Modern flour packing machines are designed with energy-efficient features, decreasing their carbon footprint.

- Materials Choice: Producers can select eco-friendly packaging materials, aligning with consumer preferences for sustainable products.

Innovations in Flour Packing Machines

Embracing Technological Advancements

As technology advances, so do flour packing machines. Innovations in automation, data collection, and machine learning have led to even greater precision, efficiency, and predictive maintenance capabilities. These advancements ensure that flour packing machines remain at the forefront of packaging technology.

Conclusion

Flour packing machines have emerged as indispensable tools in the food industry, revolutionizing flour packaging by offering unparalleled efficiency, precision, and flexibility. In a world where consumers demand quality and sustainability, these machines play a pivotal role in meeting these expectations. As the flour industry continues to evolve, the adoption of cutting-edge flour packing machines will be essential for producers aiming to thrive in this competitive market. By embracing automation and sustainability, the food industry can deliver top-quality flour products while minimizing its environmental impact, setting a promising course for the future.

No comments yet