Rubber conveyor belts have a major role in countless industries, silently handling the transportation of bulk materials across diverse environments. From the scorching heat of steel mills to the frigid depths of mines, these belts endure wear and tear while ensuring efficient and reliable operation.

But with a variety of types available, choosing the right one can be daunting. Let's delve into the fascinating world of rubber conveyor belts, understanding their construction, varieties, and suitable applications.

What is a Rubber Conveyor Belt?

At its core, a rubber conveyor belt is a continuous loop of fabric, typically polyester or nylon, encased in layers of rubber compounds. This construction imparts strength, flexibility, and specific properties depending on the chosen rubber type and ply configuration. The conveyor belt carries materials over rollers, powered by a drive pulley, forming the backbone of numerous material handling systems.

Diving into the Conveyor Belt Types:

- General Purpose Belts: These versatile workhorses handle a wide range of non-abrasive, non-oily materials like sand, gravel, and packaged goods. They offer a balance of affordability and durability, making them ideal for low-demand applications.

- Heat-Resistant Belts: Designed to withstand elevated temperatures, these belts find use in industries like asphalt, cement, and food processing. They employ heat-resistant rubber compounds like silicone or nitrile to prevent softening, melting, or degradation under thermal stress.

- Oil-Resistant Belts: Handling oily materials like coal or food scraps requires belts resistant to oil and grease. Nitrile rubber is a common choice for these applications, as it exhibits excellent resistance to hydrocarbon-based lubricants and fuels.

- Flame-Resistant Belts: Safety is paramount in industries like mining and chemical processing. These belts incorporate flame-retardant additives to minimize fire risk and self-extinguish in case of ignition, ensuring operator safety and compliance with stringent fire regulations.

- Food-Grade Belts: Conveying food items mandates utmost hygiene and safety. Food-grade belts comply with stringent FDA regulations, often made with silicone or polyurethane due to their non-toxic nature and ease of cleaning.

- Steel Cord Reinforced Belts: When dealing with heavy-duty applications involving high tension or long distances, steel cord reinforced belts offer superior strength and stability. The steel cords embedded within the carcass provide exceptional tensile strength, enabling them to handle demanding loads over extended distances.

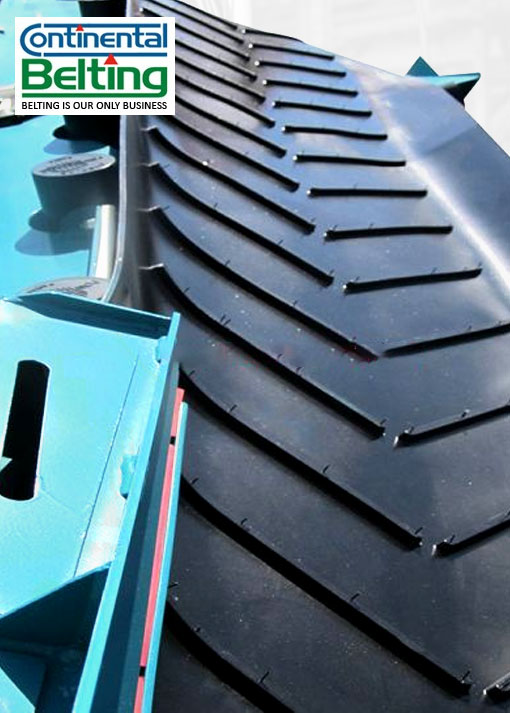

- Specialty Belts: Beyond the standard categories, numerous specialty belts address specific needs. Cleated belts prevent material slippage on inclines, while chevron belts offer superior lateral stability. Anti-static belts dissipate static electricity, crucial in areas with flammable materials.

Choosing the Right Rubber Conveyor Belt:

Selecting the ideal conveyor belt requires careful consideration of several factors:

- Material being conveyed: Abrasiveness, temperature, and chemical properties of the material dictate the belt's composition.

- Capacity and distance: Load weight and travel distance influence the required strength and tension rating.

- Environment: Operating temperature, exposure to oil, dust, or moisture, and safety requirements guide specific features.

- Budget: Costs vary depending on belt type, size, and complexity.

Consulting with conveyor belt manufacturers and considering professional assessments ensures you choose the belt that optimizes performance, maximizes durability, and minimizes costs.

Rubber conveyor belts, although seemingly simple, are marvels of engineering, playing a critical role in diverse industries. You can ensure the smooth and efficient operation of your material handling systems for years to come by understanding their types, functionalities, and selection factors

No comments yet